85

Cylinder and piston

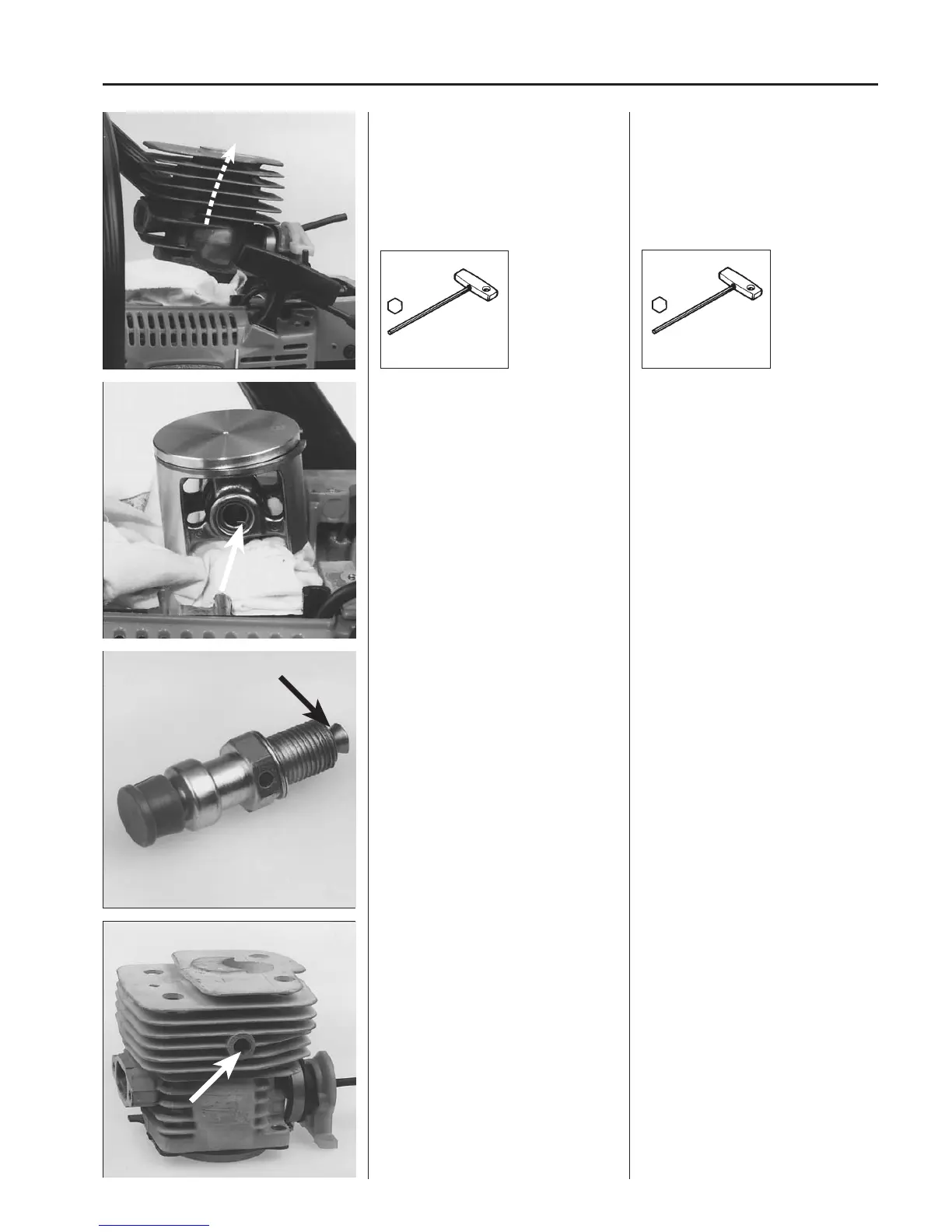

7

502 50 57-01

504 90 00-02

Release the cylinder screws and the screw

which holds the spring element to the

cylinder (mod. 2095).

Dismantle the piston from the connecting

rod.

Fitting

Mod. 625/630/670

Mod. 2077/2083

Mod. 2095

Inspect the piston and cylinder as per

chapters ”Cleaning, inspection” and ”Ana-

lysis and procedure”.

Decompression valve

Mod. 2083 and 2095 are fitted with de-

compression valves.

Check that the valve disc seals tightly. If

necessary rub down with grinding paste.

Release the cylinder screws. Use tool

502 50 57-01 (3/16") for mod. 626/630/

670 and mod. 2095.

Use tool 504 90 00-02 for mod. 2077/

2083.

Lift the cylinder and place a cloth in the

crankcase opening to prevent dirt from

dropping down into the crankcase.

Dismantle the piston from the connecting

rod.

Place a cloth in the crankcase opening to

prevent the piston bolt’s circlip from falling

down if it should be dropped.

Use a pair of flat pliers to remove the

circlip.

Fitting

Mod. 625/630/670

Mod. 2077/2083

Mod. 2095

Before fitting the piston and cylinder refer

to chapters ”Cleaning, inspection” and

”Analysis and procedure”.

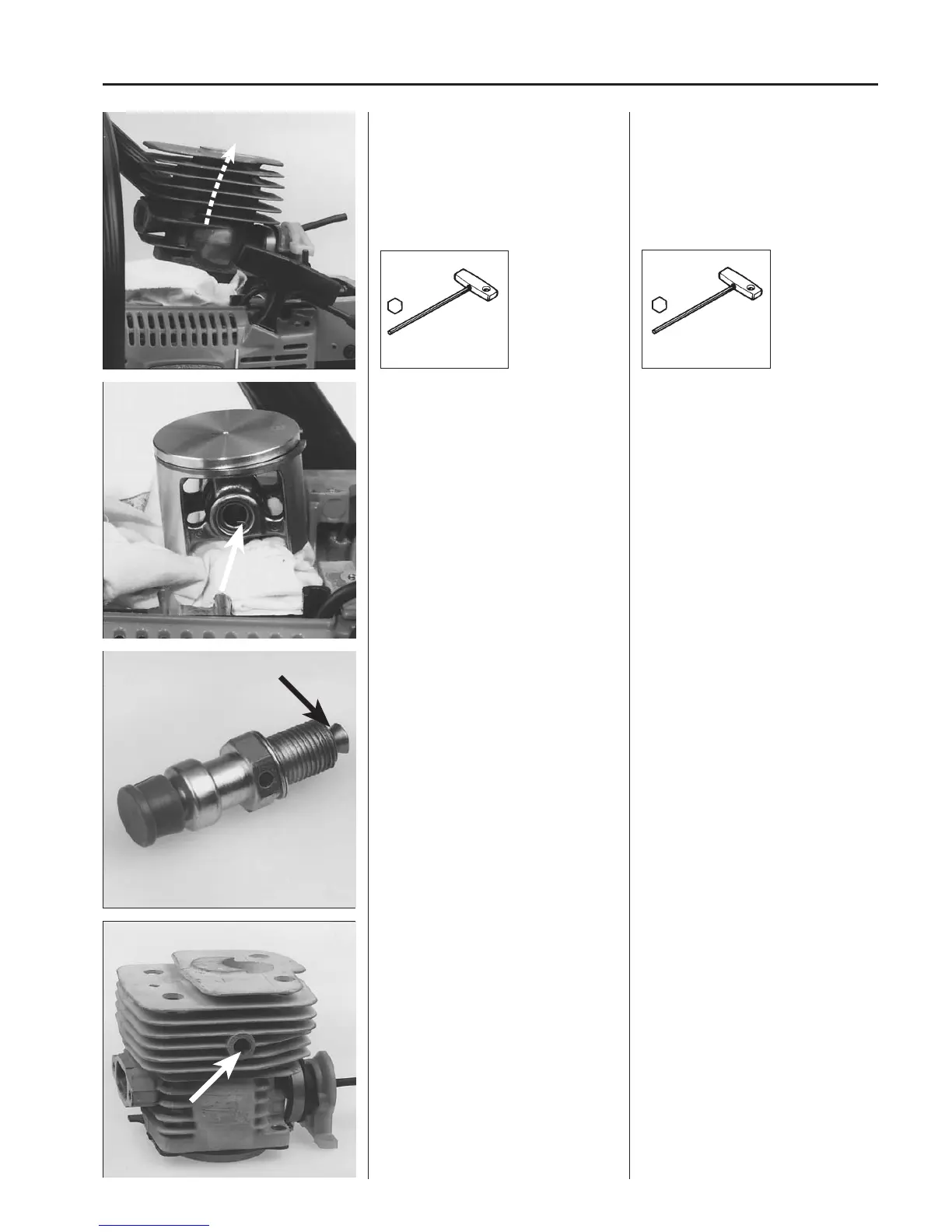

Decompression valve

Mod. 2083 and 2095 have a decom-

pression valve fitted in the cylinder.

It is important that this is tight for the

engine to provide full power.

Rub the valve disc with fine grinding paste

if it is not tight.

Wash the valve carefully to remove all the

grinding paste after rubbing.

Check that the outlet holes in the valve

are open, including the hole in the cylin-

der wall.

Clean if necessary.

Check that the outlet holes in the valve

are open, including the hole in the cylin-

der wall.

Loading...

Loading...