PRESSER

FOOT

AND

FEED

DOG

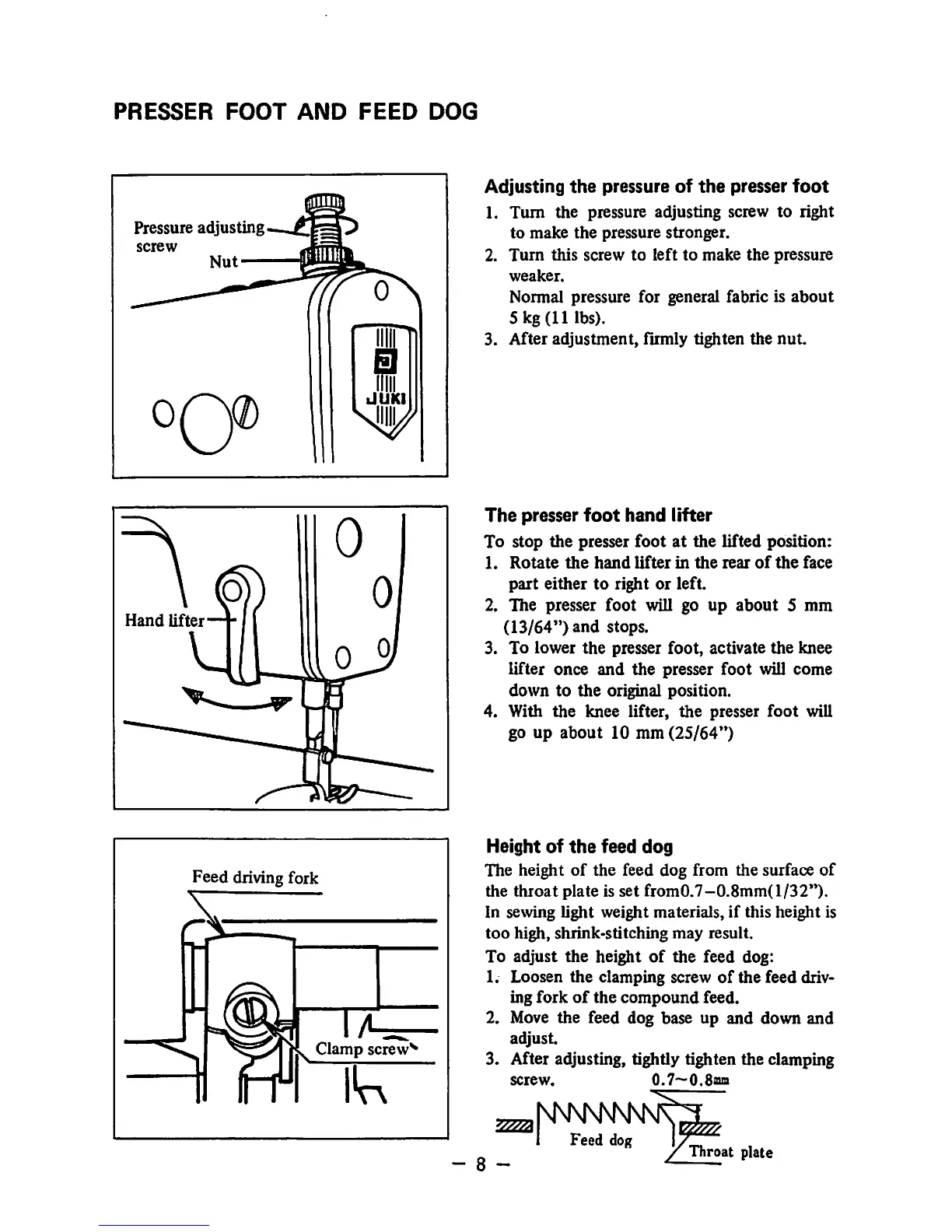

Pressure

adjusting

screw

Nut

—

0

Hand

hfter

Hill

"

JUKI

N!|^

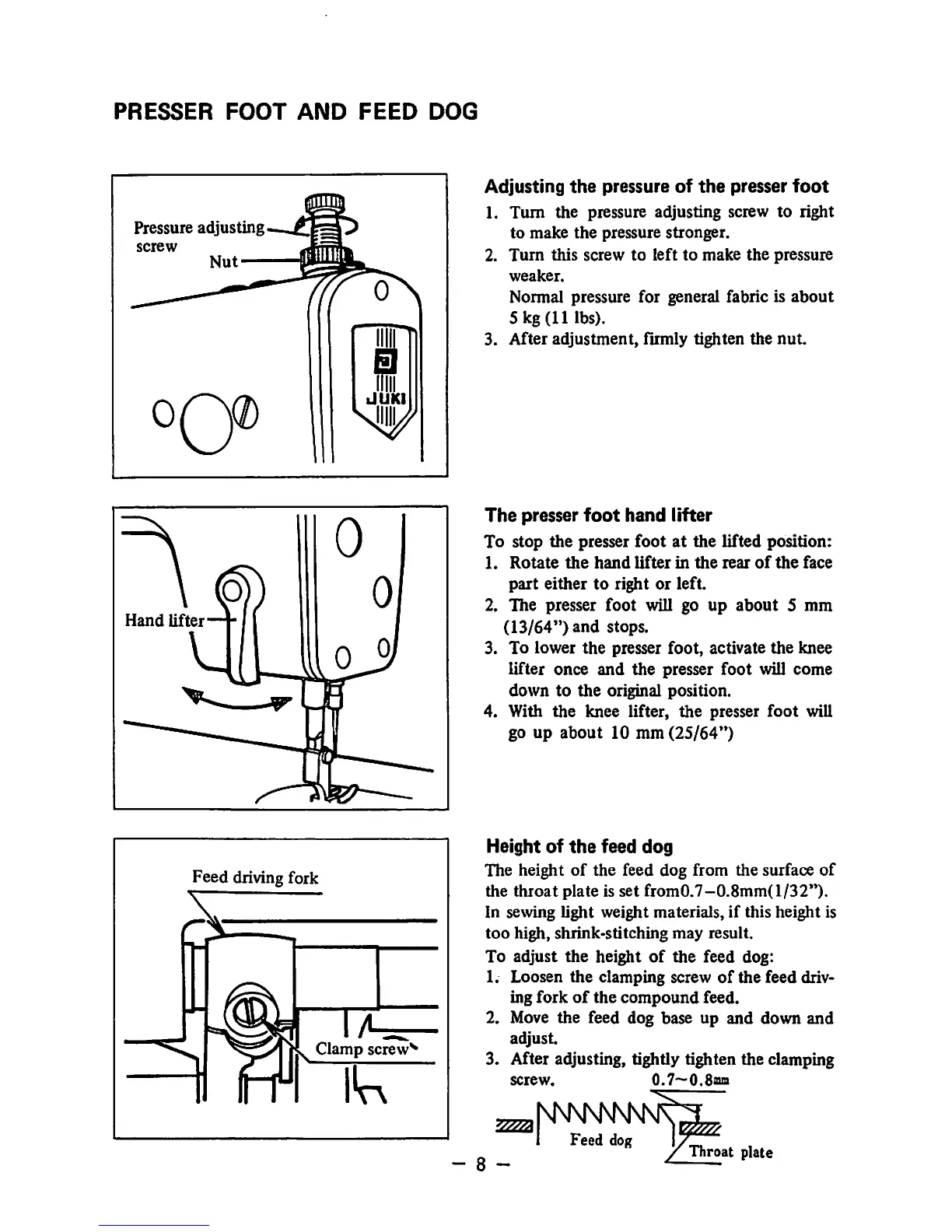

Feed driving fork

~T7=

Clamp

screw*"

lU

Adjusting

the

pressure

of

the

presser

foot

1.

Turn

the

pressure adjusting screw

to

right

to

make

the

pressure

stronger.

2.

Turn

this

screw to

left

to make

the

pressure

weaker.

Normal pressure

for

general fabric is

about

5 kg (11 lbs).

3.

After

adjustment,

firmly tighten the

nut.

The

presser

foot

hand

lifter

To stop the presser

foot

at

the

lifted position:

1.

Rotate

the

hand

lifter

in

the

rear

of

the

face

part

either

to

right or left.

2. The presser foot will go up

about

5 mm

(13/64")

and

stops.

3. To

lower

the

presser

foot,

activate

the

knee

lifter

once

and

the

presser

foot

will

come

down

to

the

original position.

4. With

the

knee

lifter,

the

presser

foot

will

go up

about

10 mm

(25/64")

Height

of

the

feed

dog

The height of the feed dog from the surface

of

the

throat

plate

is set

from0.7-0.8mm(l/32").

In sewing light weight materials, if this height is

too

high, shrink-stitching

may

result.

To

adjust

the

height

of

the

feed dog:

1.

Loosen

the

clamping screw

of

the

feed

driv

ing

fork

of

the

compound

feed.

2. Move the feed dog base up and down and

adjust

3. After adjusting, tightly tighten the clamping

screw.

0.7~0.8om

- 8 -

Feed

dog

Throat plate

Loading...

Loading...