08

LZ2290A

■ Options ■ Spec

■ When you place orders

●Presser foot connecting

components

●Without automatic thread trimmer ●With automatic thread trimmer

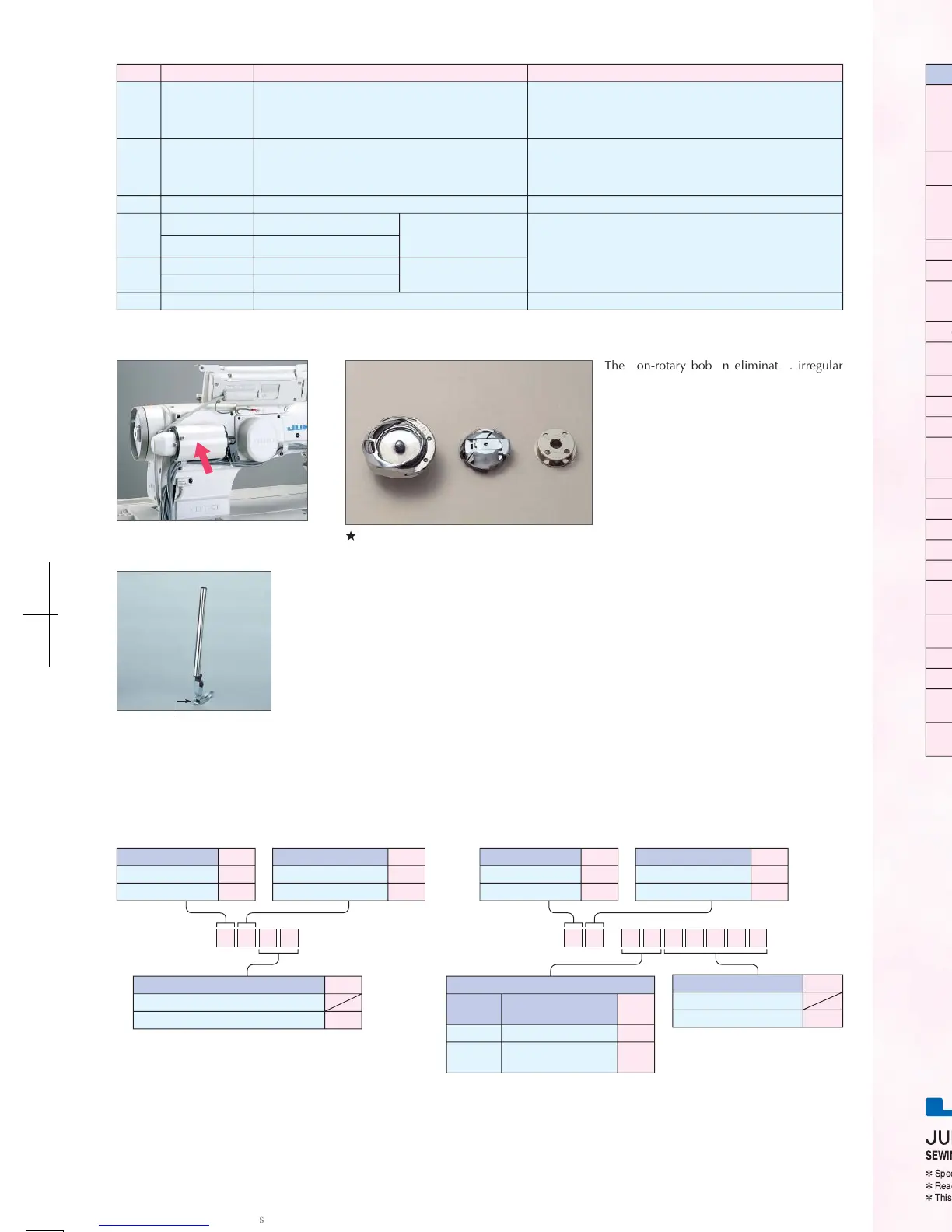

● AK121 Auto-lifter (pedal-driven) ● Non-rotary bobbin

✽Place a separate order for the presser foot

The non-rotary bobbin requires an exclusive hook,

bobbin and bobbin case.

Please note when placing orders, that the model name should be written as follows:

● To order, please contact your nearest JUKI distributor.

LZ2290A 7

Machine head type Code

Standard S

Dry-head D

Type Code

Standard S

Anti-material-slip type U

Machine head type Code

Standard S

Dry-head D

Type Code

Standard S

Anti-material-slip type U

Automatic reverse feed function Code

Not provided

Provided 0B

For LZ-2290A-SU (anti-material-slip capability),

select "Not provided."

Wiper/Automatic reverse feed function

Wiper

Automatic

reverse feed function

Code

Provided Provided WB

Not

provided

Provided 0B

Auto-lifter Code

Not provided

Auto-lifter (pedal-driven) AK121

M

Model nam

Type

Max. sew

i

Max. zigza

Needle th

Max. Stit

c

Lift of the

Hook

Thread tak

Needle (at

Number of

Max. num

Continuou

Input func

Bobbin th

Machine

h

Lubricatio

Lubricatin

Distance f

Bed size

Power re

q

Power con

Total weig

Custom pa

memory c

(Replaceable presser bar)

Hook

235-23152

Bobbin case (asm.)

235-22550

Bobbin

235-23004

✽ “sti/min”

Model Part No. Description Features

–– 400-10795 Automatic reverse feed kit

–– 400-03640 Optional switch kit

AK121 GAK-A21000B0 Auto-lifter (pedal-driven) ––

––

D1501-583-H00 Presser bar

D1502-583-H00 Presser connecting rod

––

B1551-586-000 Presser foot connecting foot

SS-7090910-TP Screw

–– 225-26578 Hard-point hook

Presser foot connecting

components

(Replaceable presser bar)

Presser foot connecting

components

When this device is installed, the LZ-2290A-

MM

(without

automatic thread trimmer) can perform reverse feed operation.

(The mirroring switch for scallop stitching is used as the push-

button-type reverse feed switch.)

This handy switch is used to control various functions

*

. It is most

effective when operating the machine in a standing position.

(

✽

Needle up/down correction, 1-stitch correction, reverse-stitch correction,

auto lifter and thread trimmer, etc.)

The aforementioned parts are used when a lockstitching type

presser foot is installed on the machine.

The blade point of this hook prevents abrasion.

✽

✽

✽

The non-rotary bobbin eliminates. irregular

stitches which have a tendency to occur at

some sewing speeds and bobbin-thread

tension fluctuations which have a tendency

to occur according to the bobbin thread

remaing on the hook.

Since the bobbin thread is fed withot

rotating the bobbin, the bobbin never idles.

Loading...

Loading...