l.

2.

3.

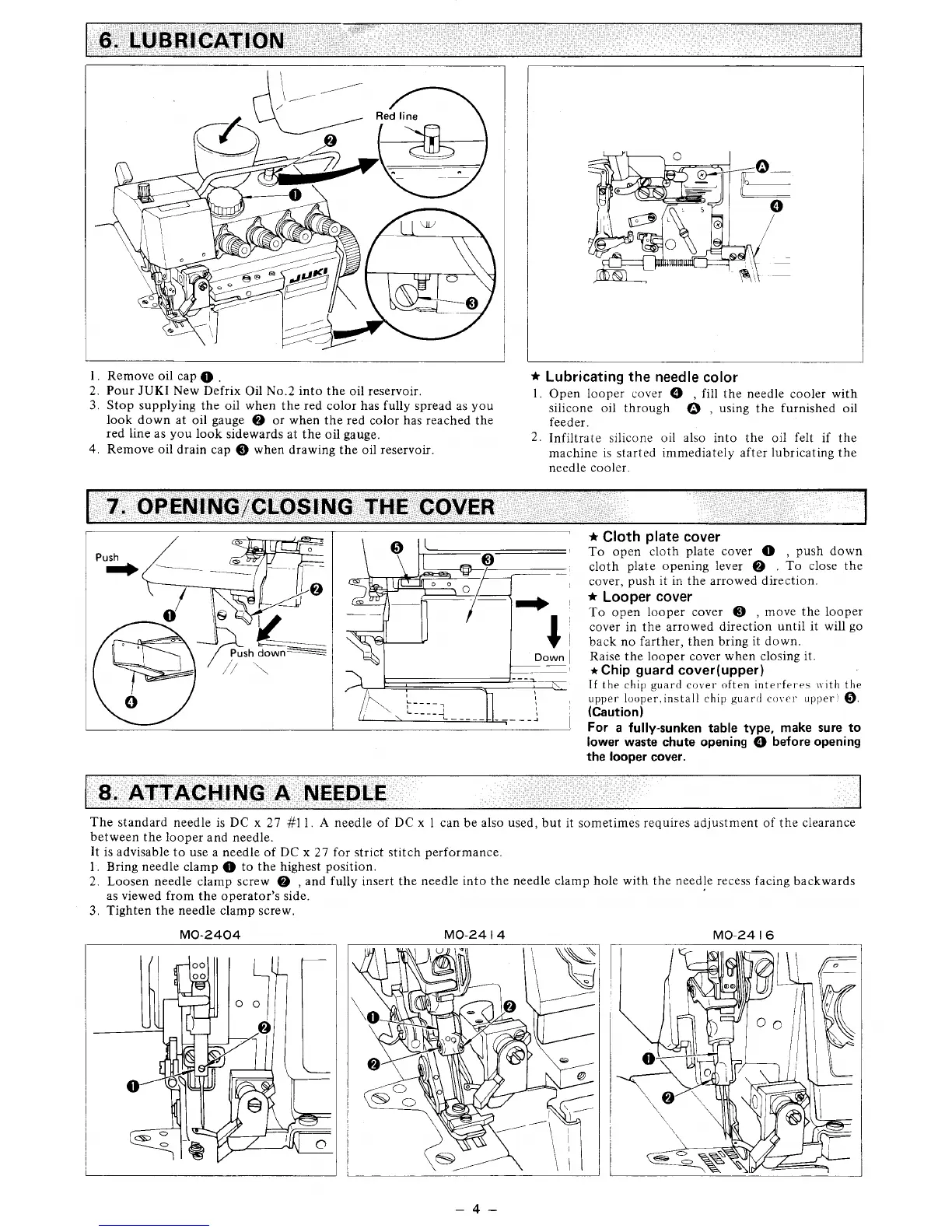

Remove oil cap

()

.

Pour

JUKI New Defrix

Oil No.2

into

the oil reservoir.

Stop supplying

the oil

when

the red color has fully spread

as

you

look down at

oil

gauge

@

or when

the

red

color

has

reached the

red line

as

you

look

sidewards

at the oil

gauge.

Remove oil

drain cap

@

when

drawing the oil

reservou.

*

Lubricating

the

needle

color

l.

Open looper cover

O

,

tltt the needle

cooler

with

silicone oil through

6

,

using

the

furnished

oil

feeder.

2.

Infiltrate silicone orl

also

into the oil

fett

if the

machine

is

started

immediately after

lubricating

the

needle cooler.

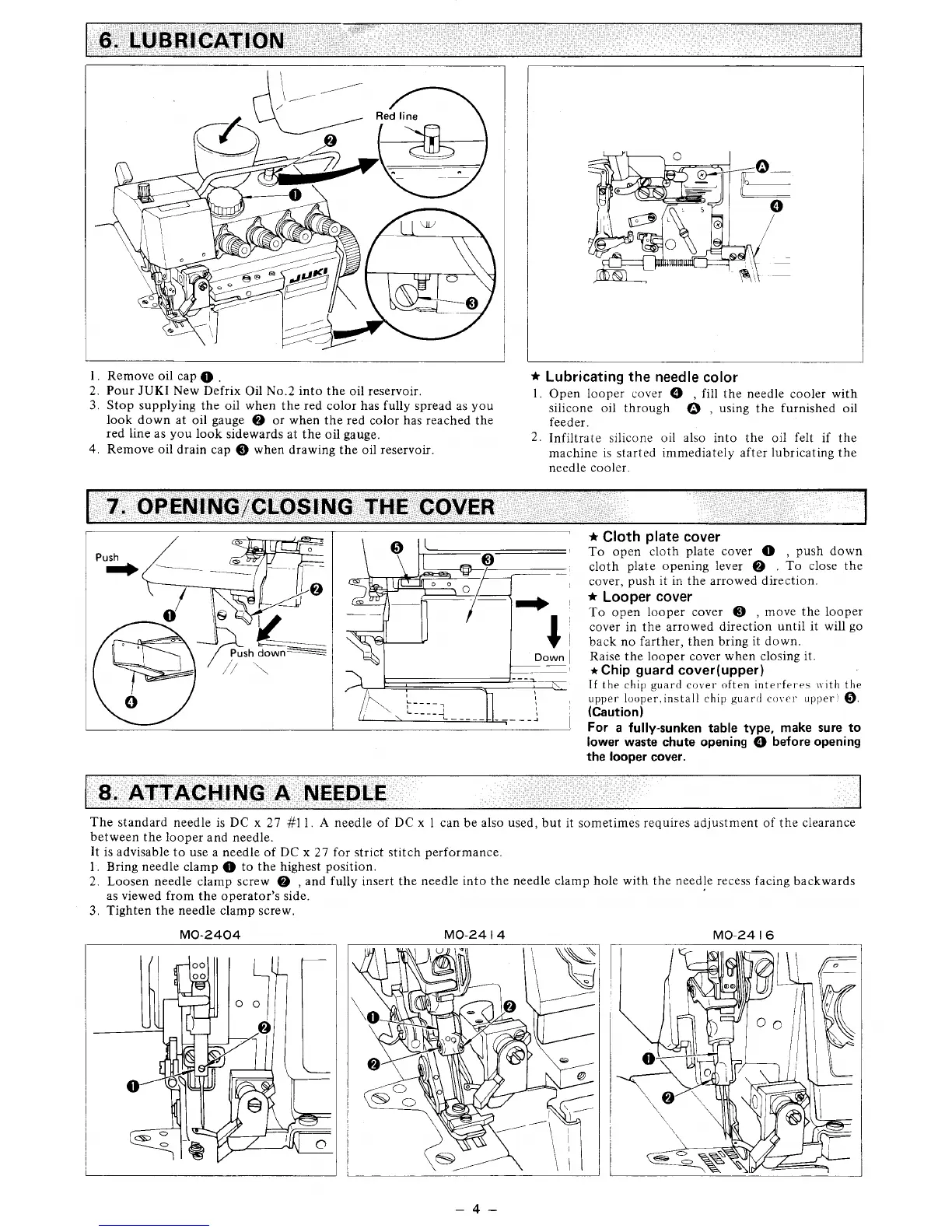

7 .

OP

EN

I NG

/CLOS

I NG THE

COVER

*

Cloth

plate

cover

To open

cloth

plate

cover

O

,

push

down

cloth

plate

opening lever

O

To close the

cover,

push

it in the

arrowed

direction.

*

Looper

cover

To open

looper cover

@

,

move

the looper

cover in the arrowed

direction until

it will

go

back no

farther, then bring

it

down.

Raise

the looper cover when closing

it.

*

Chip

guard

cover(upper)

If the

chip

guard

cover

often interferes

with

the

upper looper. install chip

guarrl

covet'

upper

)

@.

(Caution)

For

a fully-sunken

table type,

make

sure to

lower waste chute opening

@

before opening

the looper

cover.

8.

ATTACHING

A NEEDLE

The

standard needle is DC

x 27

#1

1.

A

needle of

DC x

I can be also

used,

but it sometimes requires adjustment of the clearance

between

the looper

and needle.

It

is advisable

to use a needle of DC x2'7 for strict stitch

performance.

1. Bring needle clamp

O

to

the

highest

position.

2. Loosen needle clamp screw

@

,

and

fully

insert the

needle into the

needle clamp hole with the needle recess facing

backwards

as viewed from

the operator's side.

3. Tighten

the needle clamp

screw.

MO-2404 MO-24t

4 MO-24 |

6

-4-

Loading...

Loading...