Do you have a question about the JUMO dTRON 304 plast and is the answer not in the manual?

Provides a comprehensive overview of the controller's features and capabilities.

Explains symbols and formatting used in the manual for clarity.

Details the coding system for specifying instrument models and configurations.

Lists the items included in the standard package upon purchase.

Describes optional add-ons and peripherals available for the instrument.

Specifies environmental requirements for safe and optimal installation.

Provides physical dimensions and panel cutout details for installation.

Explains how to install multiple units adjacent to each other.

Guides the user through the process of securing the instrument in its panel cutout.

Details the procedure for safely removing the main controller unit from its housing.

Covers essential safety and general guidelines for electrical wiring.

Illustrates the electrical isolation principles and voltage ratings for various connections.

Presents detailed wiring schematics for different instrument types and options.

Explains how to activate internal termination resistors for serial communication.

Details the wiring for connecting the PROFIBUS-DP communication interface.

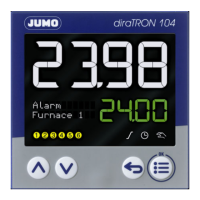

Describes the instrument's display elements and front panel buttons for user interaction.

Explains the hierarchical structure for accessing instrument parameters and settings.

Details how to restrict access to different parameter levels for security.

Guides users on how to input values and interpret on-screen prompts.

Covers the basic operation of the controller in its default fixed-setpoint mode.

Explains how to configure and operate the instrument as a program controller.

Lists and describes the process variables and setpoints accessible at the operator level.

Discusses the use of parameter sets and their application in different control scenarios.

Illustrates a practical example of setting up a 2-state controller with PI action.

Details the configuration options for analog input signals and sensor types.

Covers the setup of controller types, control actions, and operating modes.

Explains the configuration of operating modes like ramp and program generation.

Details the specific configuration for warm-up ramps in hot-channel applications.

Explains how to configure limit comparators for monitoring process variables.

Describes the configuration of analog and binary outputs, including numbering.

Details how to assign functions to binary inputs and limit comparators.

Covers the configuration of display elements, units, and time-out settings.

Explains the setup of communication interfaces like Modbus and PROFIBUS-DP.

Guides users on automating the process of optimizing controller parameters.

Provides methods to verify and adjust the controller's tuning for optimal performance.

Explains how to implement mathematical and logical operations for advanced control.

Details configurations for specific controller types like difference, humidity, or ratio control.

Highlights safety precautions, especially regarding electrostatic discharge during module replacement.

Describes how to identify specific modules using their sales numbers.

Provides instructions on how to safely detach the controller module from its housing.

Explains the process of selecting slots and installing optional modules into the instrument.

Lists detailed specifications, measurement ranges, and accuracy for inputs and outputs.

Provides a guide to understanding and resolving various error and alarm messages.

| Type | Compact controller |

|---|---|

| Operating temperature | 0 to 50 °C |

| Storage temperature | -20 to 70 °C |

| Display | LED |

| Input | Thermocouple, RTD, voltage, current |

| Output | Relay |

| Power Supply | 24 V AC/DC |

| Communication | RS485, Modbus RTU |

| Protection class | IP65 |

| Dimensions | 96 x 96 x 95 mm |

| Input channels | 1 |