……………………………………………………………….…………………………

……………………………………………………………….…………………………

13 / 32

• Install a suitable pulley on the smooth shaft as close as possible to the pump: max 35 mm.

• Apply an adequate belt tension (see manufacturer’s data). Max 3000N.

• Do not use driven or driving pulleys with a pitch diameter inferior to 180 mm. Small pulleys

require a high belt tension which may cause premature wear to the bearing or transmission

troubleshooting.

Drive min. pulley pitch diam. Belts LC pump max. speed

mm rpm

180 XPB x 3 1300

NOTE

A limited speed ratio allows a longer belts life while reducing stress on the shafts. When possible, prefer:

• pulleys with a pitch diameter bigger than the one indicated;

• motors or power take-offs with a speed similar to the one of the pump.

• Motor features

Displacement

Operating

pressure

(max. vac.)

Operating

pressure

(1 rel. bar)

Flow (at

1300 rpm)

Max

pressure

draining line

Max. pressure

motor exhaust

Model

cc/rev bar bar l/min bar bar

bar

LC300

61 125 150 83 200

LC420

72 135 175 98

5 5

200

• Fluid: mineral oil for hydraulic systems in compliance with ISO/DIN.

Temperature Optimum viscosity Max. viscosity allowed

° C cSt cSt

-20 / +80 12 - 100 750

• Filtration: class 19/16 contamination according to ISO 4406

to be obtained with a ß

x

= 75 filter

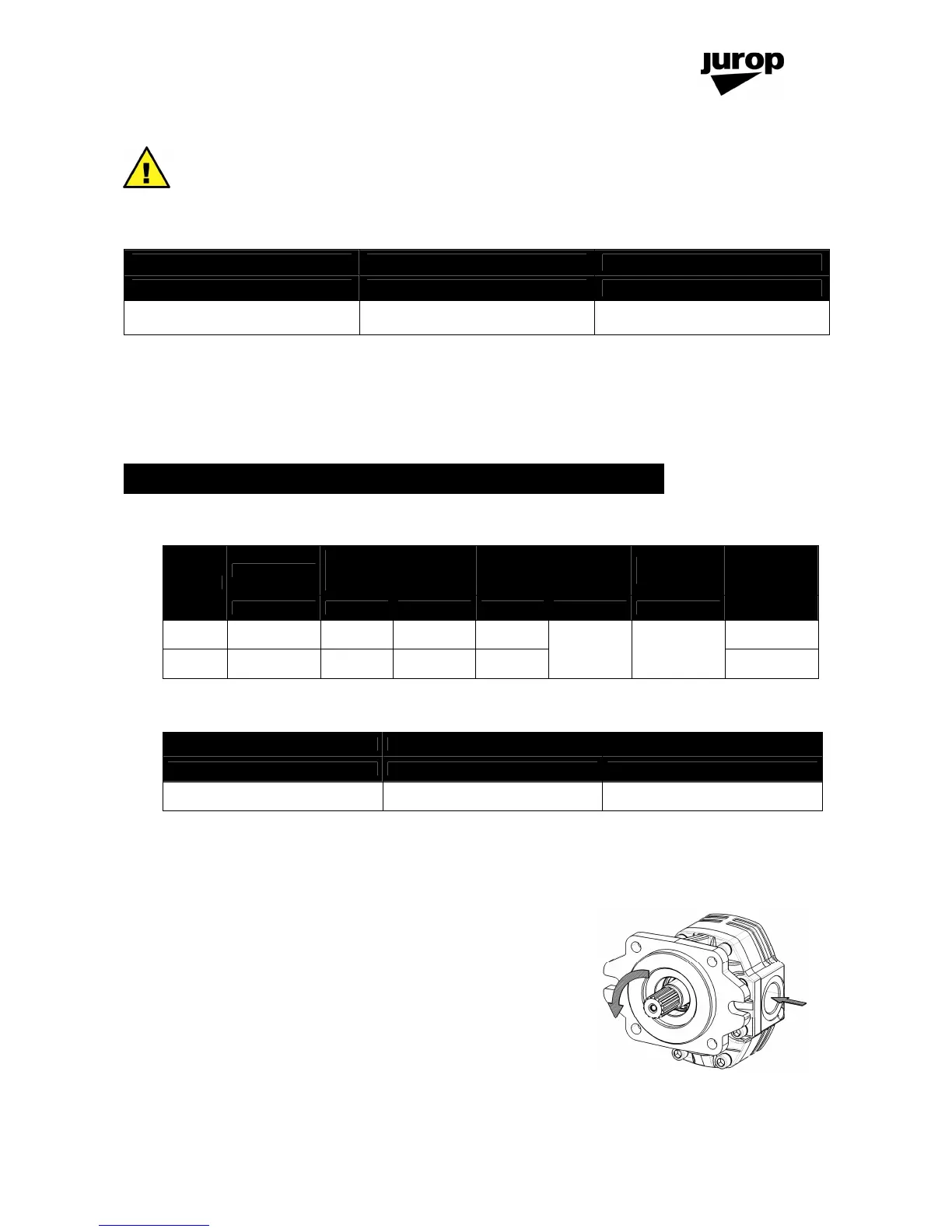

• Check circuit connections

:

they must be applied in the same

rotation direction as that indicated by the arrow on the pump

front flange.

• Draining: connect directly to the tank above the maximum oil

level. Operating without draining line may damage the motor.

HYDRAULIC DRIVE

Loading...

Loading...