INSTALLATION, USE AND MAINTENANCE MANUAL – LC

Jurop SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

TEL. +39 0434 636811 FAX. +39 0434 636812

http://www.jurop.it

e-mail: info@jurop.it

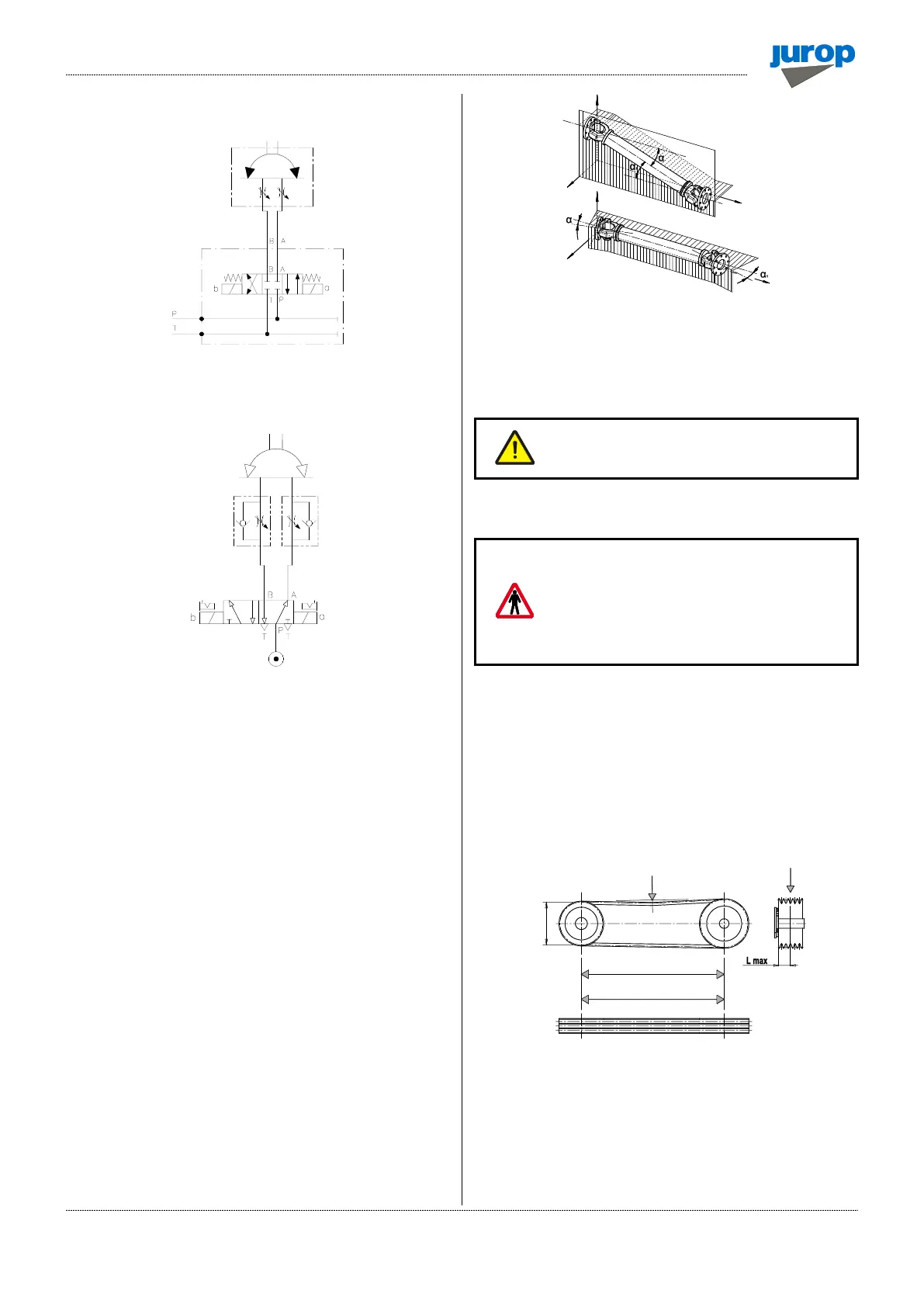

• The following figure shows a possible schematic view of a correct

hydraulic connection.

Pic. 4.6

• The following figure shows a possible schematic view of a

pneumatic connection.

Pic. 4.7

• In case of interruption of the pneumatic or hydraulic supply, the

inverter of the suction unit remains in the same position it was when the

failure occurred.

4.9. Pump mounting - Drive connection

• For the machines of this series, the allowed power transmissions

are:

− Direct transmission (e.g.: from agricultural cardan shaft);

− Oil hydraulic transmission (e.g.: hydraulic motor).

• Protect with a fixed or interlocked guard and signal with

pictograms the power transmission chosen and applied by the final

installer, if there is the possibility that the operator will come into

contact during handling.

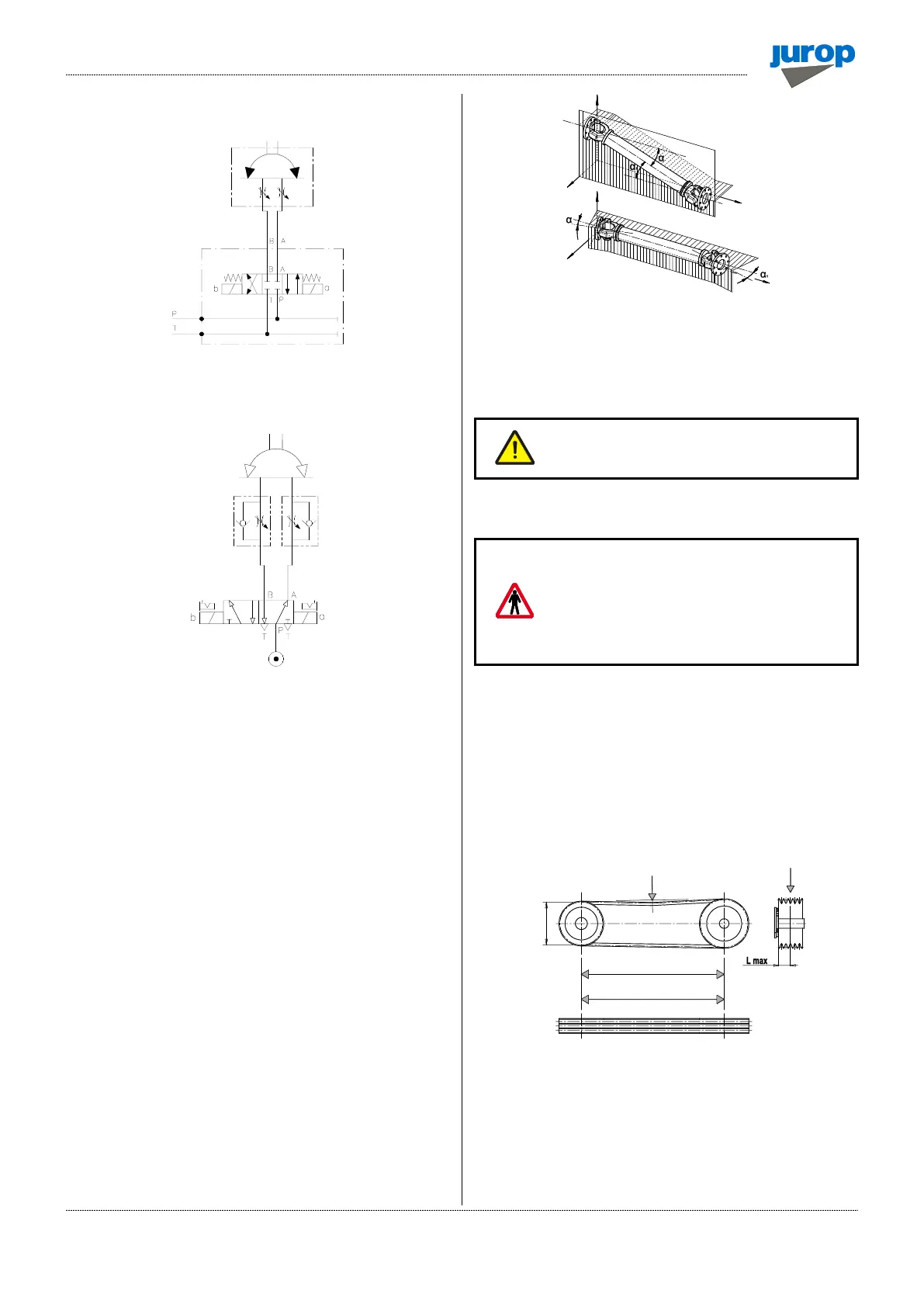

A) Cardan shaft drive

• Use telescopic cardan shafts.

• In order to achieve a uniform motion of the driven shaft, the

following requirements must be met (see Fig. 4.6):

− Equal working angle α and α1 of both couplings.

− The internal fork joints must be coplanar.

− Both driven and driving shafts must be coplanar.

Pic. 4.8

• It is also recommended working with limited articulated joint angles

(max 15° at 1000 rpm and max 11° at 1300 rpm) and disengaging the

transmission for those operations requiring great angles (steering or

lifting).

Follow the rotation direction as indicated on the

front flange. Follow the instructions of the cardan

shaft’s manufacturer.

• Use the cardan guard supplied with the pump, by fixing it to the

pump itself.

Use the cardan guard supplied with the pump, by

fixing it to the pump itself. In any case, the

installation, by the final installer, must comply

with the current EC accident prevention

regulations and must be compatible with the

geometry of the protection cap supplied with the

machine.

• The protection must not be removed; in case of removal, it is the

responsibility of the final installer to provide for suitable guards

according to the assembly.

• It is the responsibility of the final installer to provide for suitable

guards, in presence of transmission shafts exposed during normal

operation.

B) Belt drive

Pic.4.9

• Install a suitable pulley on the smooth shaft as close as possible to

the pump: max 35 mm.

• Apply an adequate belt tension (see manufacturer’s data). Max

3000N.

• Do not use driven or driving pulleys with a pitch diameter inferior

to 180 mm. Small pulleys require a high belt tension which may cause

premature wear to the bearing or transmission troubleshooting.

ALINGN PULLEY GROVES

AND BELTS

Loading...

Loading...