(No.YD023)1-7

Fig.4-2f

4.3 Electrical adjustment [VHS SECTION]

Note:

The following adjustment procedures are not only neces-

sary after replacement of consumable mechanical parts

or board assemblies, but are also provided as references

to be referred to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always be-

gin a service by identifying the defective points by using

the measuring instruments as described in the following

electrical adjustment procedures. After this, proceed to

the repair, replacement and/or adjustment. If the required

measuring instruments are not available in the field, do

not change the adjustment parts (variable resistor, etc.)

carelessly.

4.3.1 Servo circuit

4.3.1.1 Switching point

<UJ,UM Model>

(1) Play back the signal (A1) of the alignment tape (A2).

(2) Apply the external trigger signal to D.FF (E) to observe

the VIDEO OUT waveform and V.PB FM waveform at

the measuring points (D1) and (D2).

(3) Set the VCR to the manual tracking mode.

(4) Adjust tracking so that the V.PB FM waveform becomes

maximum.

(5) Set the VCR to the Auto adjust mode by transmitting the

code (F) from the Jig RCU. When the VCR enters the

stop mode, the adjustment is completed.

(6) If the VCR enters the eject mode, repeat steps (1) to (5)

again.

(7) Play back the alignment tape (A2) again, confirm that the

switching point is the specified value (G).

<UA Model>

(1) Play back the signal (A1) of the alignment tape (A3).

(2) Perform the above steps (2) to (6).

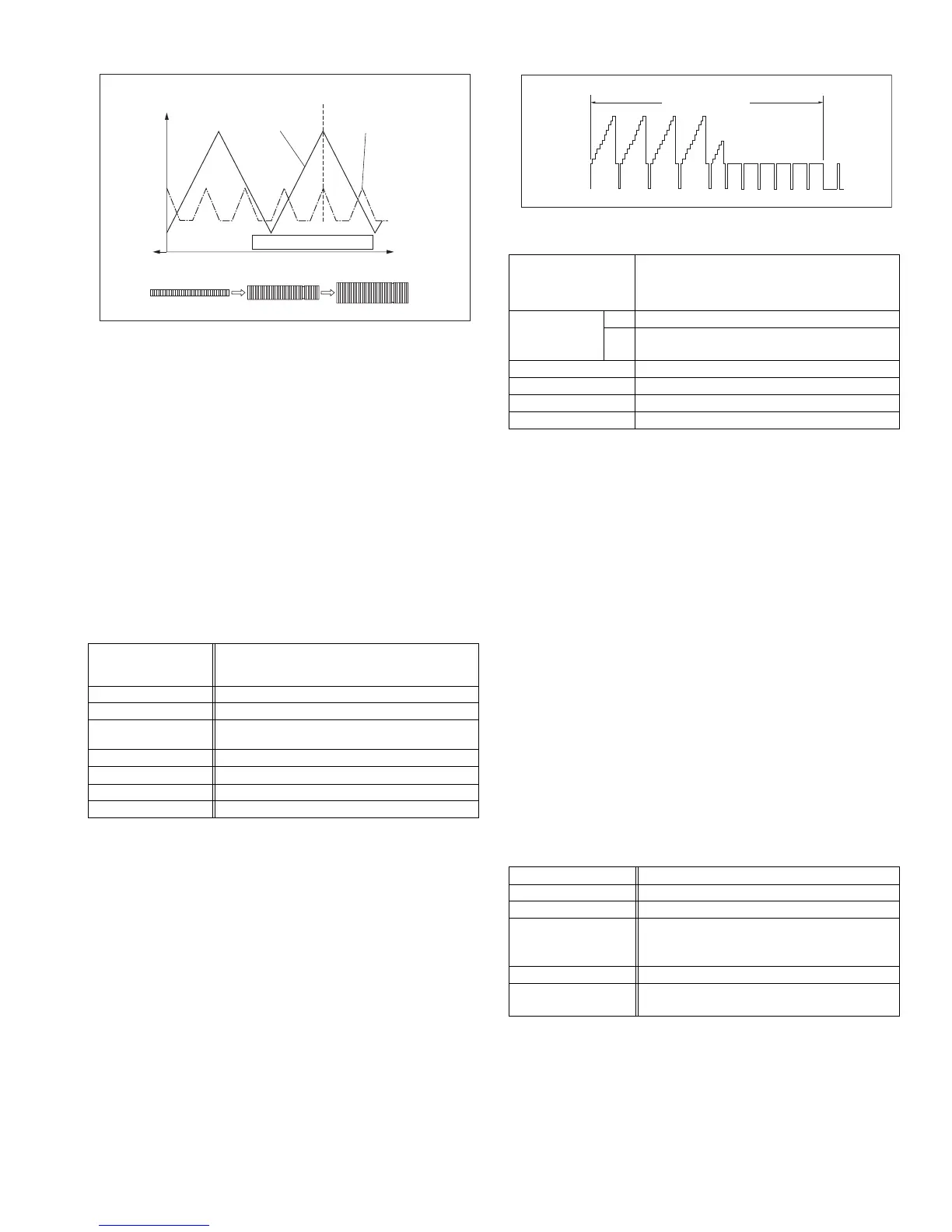

Fig.4-3a Switching point

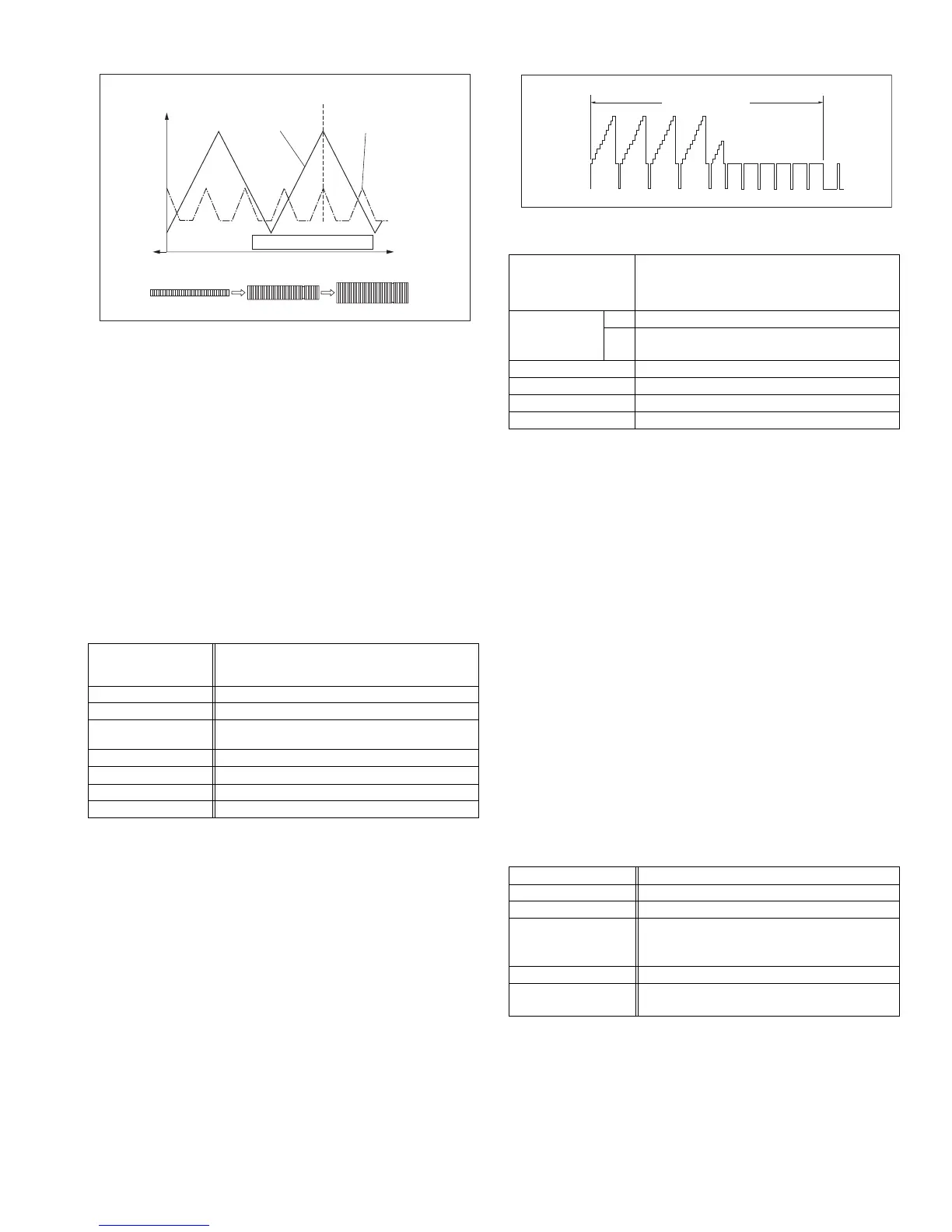

4.3.1.2 Slow tracking preset

(1) Record the signal (A2) in the mode (B1), and play back the

recorded signal.

(2) Set the VCR to the manual tracking mode.

(3) Set the VCR to the FWD slow (+1/6x) mode.

(4) Transmit the code (F) from the Jig RCU to adjust so that the

noise bar becomes the specified value (G) on the TV mon-

itor in the slow mode.

(5) Set the VCR to the Stop mode.

(6) Confirm that the noise bar is (G) on the TV monitor in the

slow mode.

<UA Model>

(1) Record the signal (A3) in the mode (B2), and play back

the recorded signal.

(2) Repeat steps (2) to (6) .

Note:

• For FWD slow (+1/6x) playback, transmit the code "43-08"

from the Jig RCU to enter the slow playback mode, and

transmit the code “43-D0” for REV slow (+1/6x) mode.

4.3.2 Syscon circuit [UA, UM MODELS]

Notes:

• When perform this adjustment, remove the Mechanism

assembly.

4.3.2.1 Timer clock

(1) Connect the frequency counter to the measuring point (D1).

(2) Connect the short wire between the short point (D2) and

Vcc (5V).

(3) Short the leads of capacitor (D3) once in order to reset

the microprocessor of the Syscon.

(4) Disconnect the short wire between the short point (D2)

and Vcc then connect it again.

(5) Adjust the Adjustment part (F) so that the output frequency

becomes the specified value (G).

Signal (A1)

(A2)

(A3)

• Stairstep signal

• Alignment tape(EP,stairstep,NTSC) [MHP-L]

• Alignment tape(LP,stairstep,PAL) [MHPE-L]

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • VIDEO OUT terminal (75 ohm terminated)

• TP106 (PB. FM)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Jig RCU: Code “43-5A”

Specified value (G) • 6.5 ± 0.5H

Adjustment tool (H) • Jig RCU [PTU94023B]

Alignment tape

[SP, stairstep]

played with the

SP head

Alignment tape

[EP(LP), stairstep]

played with the

EP(LP) head

Drum side Control head position Capstan side

X-value adjustment point

Maximum

Waveform output

Signal (A1)

(A2)

(A3)

• Ext. input

• Color (colour) bar signal [NTSC]

• Color (colour) bar signal [PAL-N]

(UA Model)

Mode (Notes)

(B1) • SP/EP

(B2) UA Model

• SP/LP

Measuring point (D) • TV-Monitor

Adjustment part (F) • Jig RCU: Code “43-71”or “43-72”

Specified value (G) • Minimum noise

Adjustment tool (H) • Jig RCU [PTU94023B]

Signal (A1) • No signal

Mode (B) • EE

Equipment (C) • Frequency counter

Measuring point (D1)

(D2)

(D3)

• IC3001 pin 44

• IC3001 pin 103

• C3054 + and -

Adjustment part (F) • C3025 (TIMER CLOCK)

Specified value (G) • 1024.008 ± 0.001 Hz

(976.5549 ± 0.0010 usec)

V.sync

Trigger point

Switching point

V. rate

Loading...

Loading...