ADJUSTMENT

~

The following four adjustments are recommended only in the

event that you have replaced a cartridge or a headshell.

Otherwise, no adjustments are required.

Note: If you change the cartridge, it is recommended to use

the headshell provided on this unit.

~~~

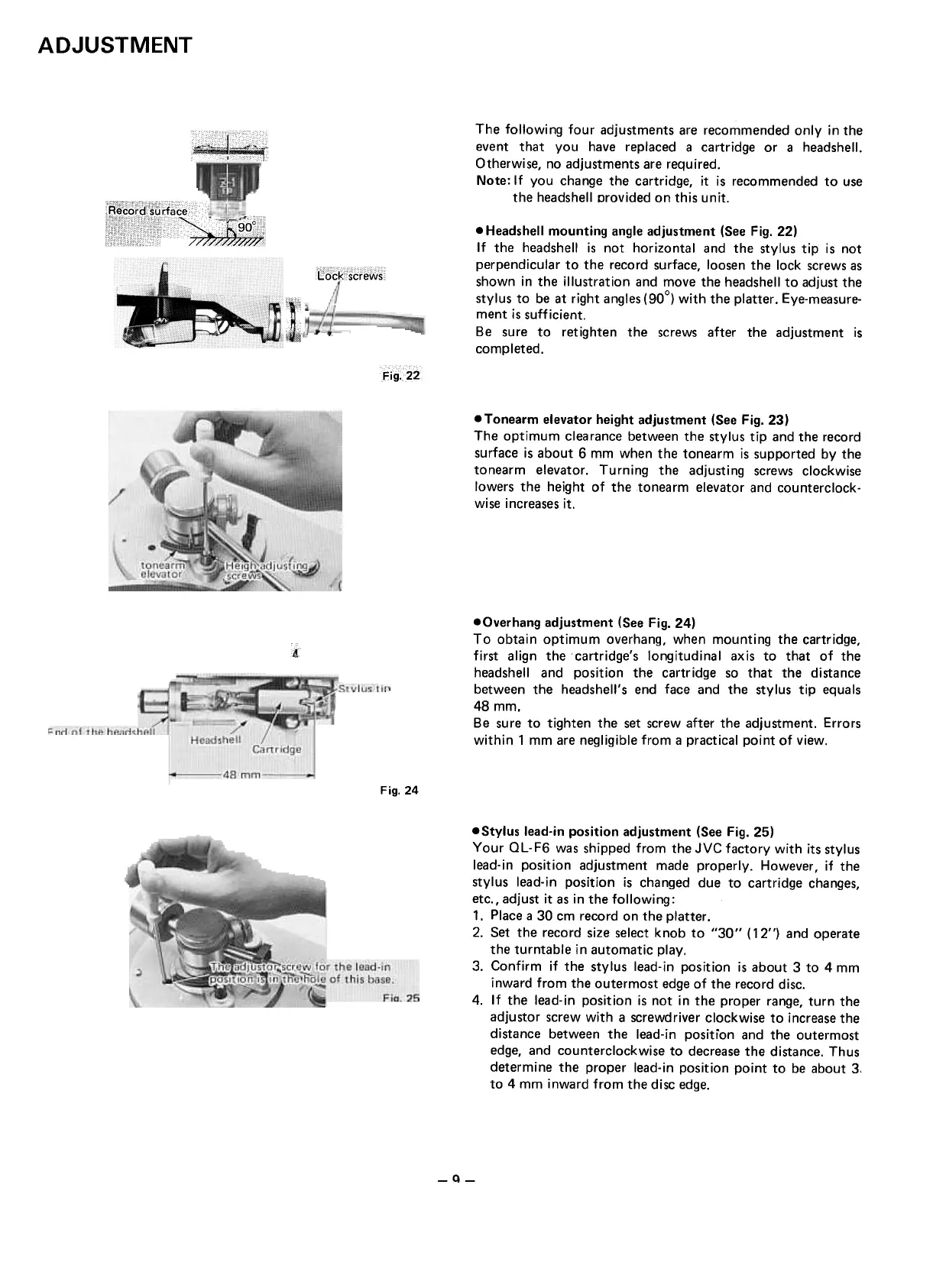

.Headshell mounting angle adjustment (See Fig. 22)

If the headshell is not horizontal and the stylus tip is not

perpendicular to the record surface, loosen the lock screws as

shown in the illustration and move the headshell to adjust the

stylus to be at right angles (900) with the platter. Eye-measure-

ment is sufficient.

Be sure to retighten the screws after the adjustment is

completed.

Fig. 22

.Tonearm elevator height adjustment (See Fig. 23)

The optimum clearance between the stylus tip and the record

surface is about 6 mm when the tonearm is supported by the

tonearm elevator. Turning the adjusting screws clockwise

lowers the height of the tonearm elevator and counterclock-

wise increases it.

j

4

.Overhang adjustment (See Fig. 24)

To obtain optimum overhang, when mounting the cartridge,

first align the cartridge's longitudinal axis to that of the

headshell and position the cartridge so that the distance

between the headshell's end face and the stylus tip equals

48mm.

Be sure to tighten the set screw after the adjustment. Errors

within 1 mm are negligible from a practical point of view.

Fig.24

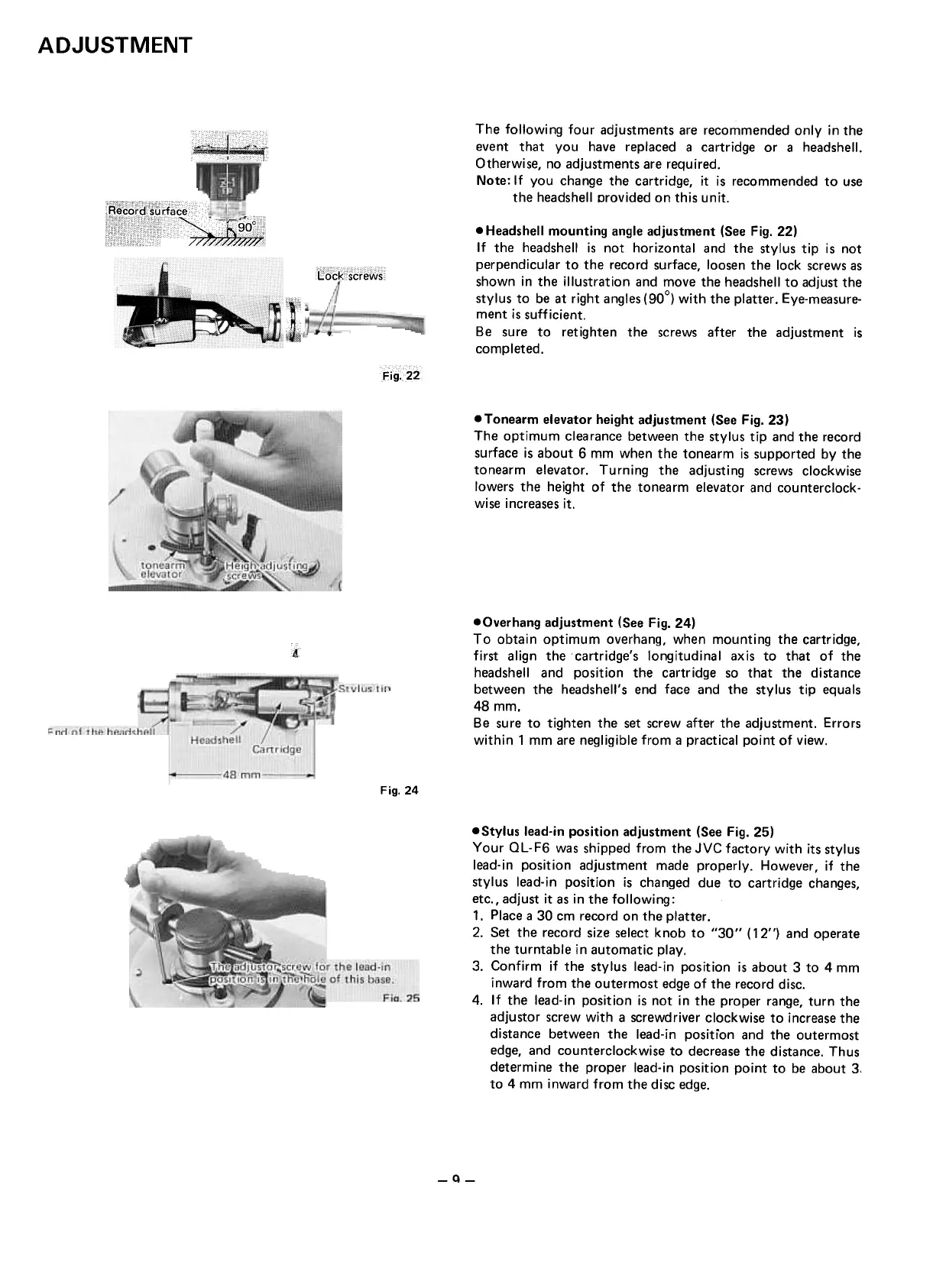

.Stylus lead-in position adjustment (See Fig. 25)

Your OL.F6 was shipped from the JVC factory with its stylus

lead-in position adjustment made properly. However, if the

stylus lead-in position is changed due to cartridge changes,

etc., adjust it as in the following:

1. Place a 30 cm record on the platter .

2. Set the record size select knob to "30" ( 12") and operate

the turntable in automatic play.

3. Confirm if the stylus lead.in position is about 3 to 4 mm

inward from the outermost edge of the record disc.

4. If the lead.in position is not in the proper range, turn the

adjustor screw with a screwdriver clockwise to increase the

distance between the lead-in position and the outermost

edge, and counterclockwise to decrease the distance. Thus

determine the proper lead-in position point to be about 3,

to 4 mm inward from the disc edge.

-Q-

Loading...

Loading...