16

At the temperatures encountered in the condenser, receiver and liquid line a certain amount of oil is always

being circulated with the refrigerant through the system by the compressor. However, at the evaporator

temperature, and with the refrigerant in a vapor state, the oil and refrigerant separate. This oil can only be

returned to the compressor by gravity or by entrainment in the suction gas. Roof installations leave no

alternative but by entrainment for oil return, so suction gas velocity and correct line sizing to maintain this

velocity are imperative. Care must be taken not to oversize the suction line in the desire for maximum

performance.

Gas velocity in vertical suction lines must not be less than 1,000 fpm (5 m/s) and preferably 1,250 to

1,500 fpm (6 to 8 m/s).

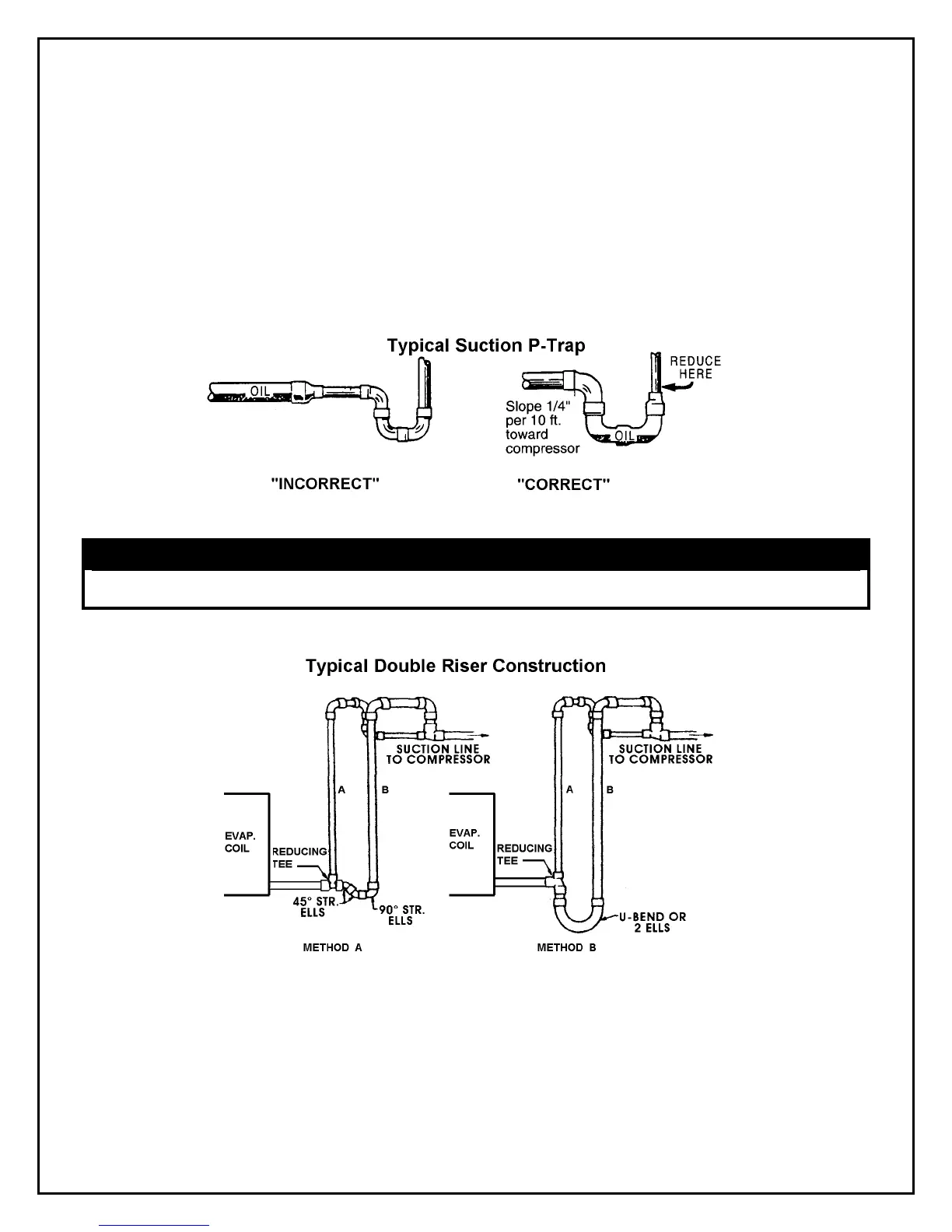

Important: A suction trap must be installed at the base of all suction risers of four (4) feet or more in order to

trap oil and allow entrainment in the suction gas.

IMPORTANT PIPING NOTE

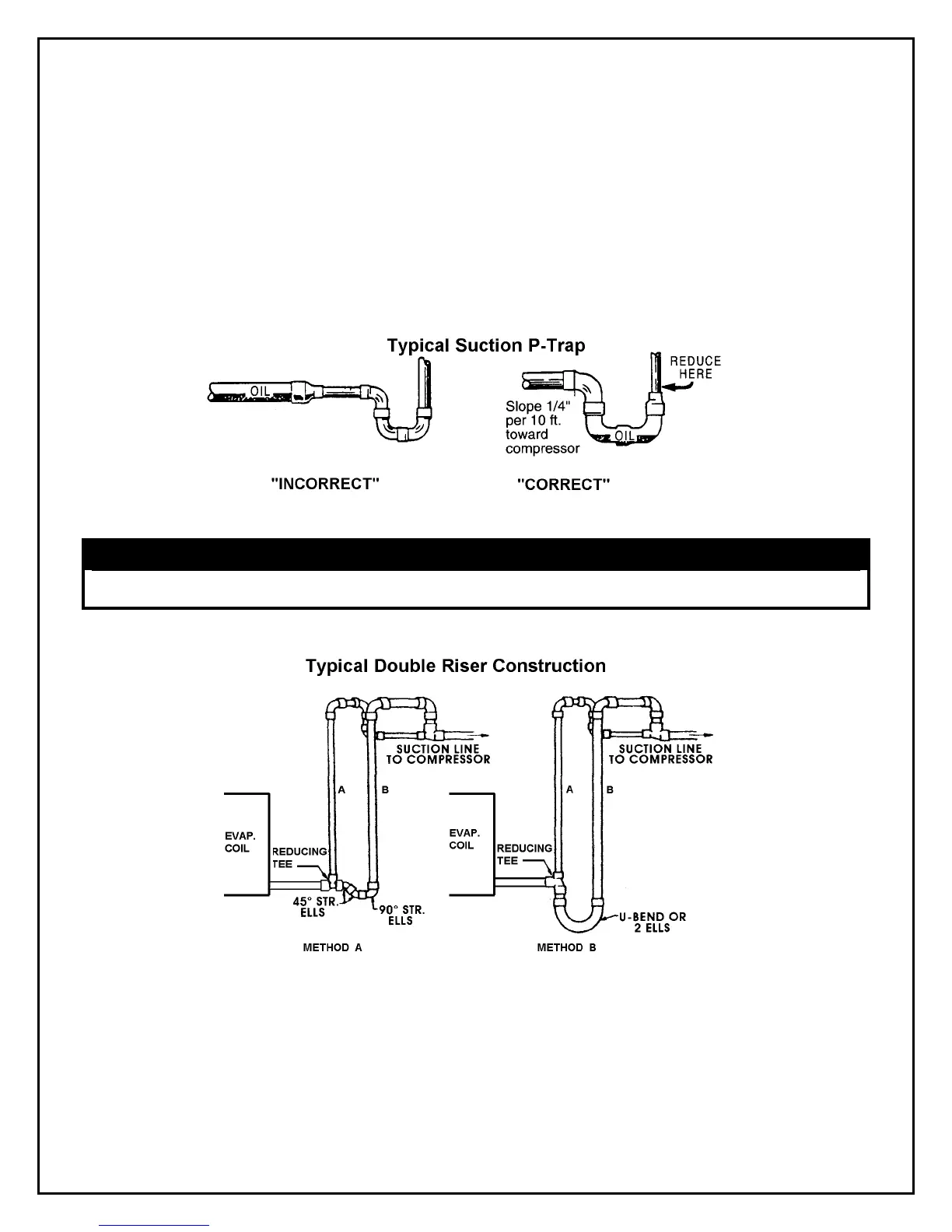

If steps of capacity control are supplied on a compressor, provisions must be made for oil return by sizing

suction risers to maintain adequate gas velocities at reduced refrigerant flow.

During the lower capacity running mode (compressor capacity control energized) oil will collect in the elbow or at

U-bend below pipe “B”. This will divert the gas and oil to flow up the smaller pipe “A” at a higher velocity.

IMPORTANT: When welding service valves or any components that may be damaged by heat, manufacturer’s

installation instructions must be adhered to. Wrapping components with a wet cloth will help to prevent damage

from heat.

IMPORTANT: All suction lines outside of the refrigerated space must be insulated.

Loading...

Loading...