24

Compressor Oils

Check to see that the oil level is 1/8 to 1/3 up on the compressor sight glass on compressors so equipped

before starting the compressor and after 15 to 20 minutes of operation.

CAUTION: Oil levels should not be allowed to go above the centre or 1/2 of the sight glass. Excessive oil levels

in the compressor can result in excessive compressor noise, higher power consumption or internal compressor

damage.

Welded hermetic compressors normally do not have sight glasses or means of determining their oil level. This

type of compressor is usually installed in packaged systems or in close proximity to the fixture.

All welded hermetic compressors are factory charged with enough oil to compensate for any piping losses up to

about 35 ft (10.7 m) (one way) remote location. In the event of any substantial oil loss due to a leak or excessive

line run, recharge as per the table below.

Add approximately 1/3 fl oz per foot (32 ml per meter) for any remote location over 35 ft (10.7 m). If in doubt of

an actual oil level, the only positive check is to remove the compressor and drain the oil (through the suction

connection) and recharge with the correct factory charge (refer to unit specifications). DO NOT

re-use drained

oil that has been exposed to the atmosphere. DO NOT re-fill, at any one time more than a total of 110 % of the

compressor’s factory specified charge. Allow time for some of the oil to circulate into the system.

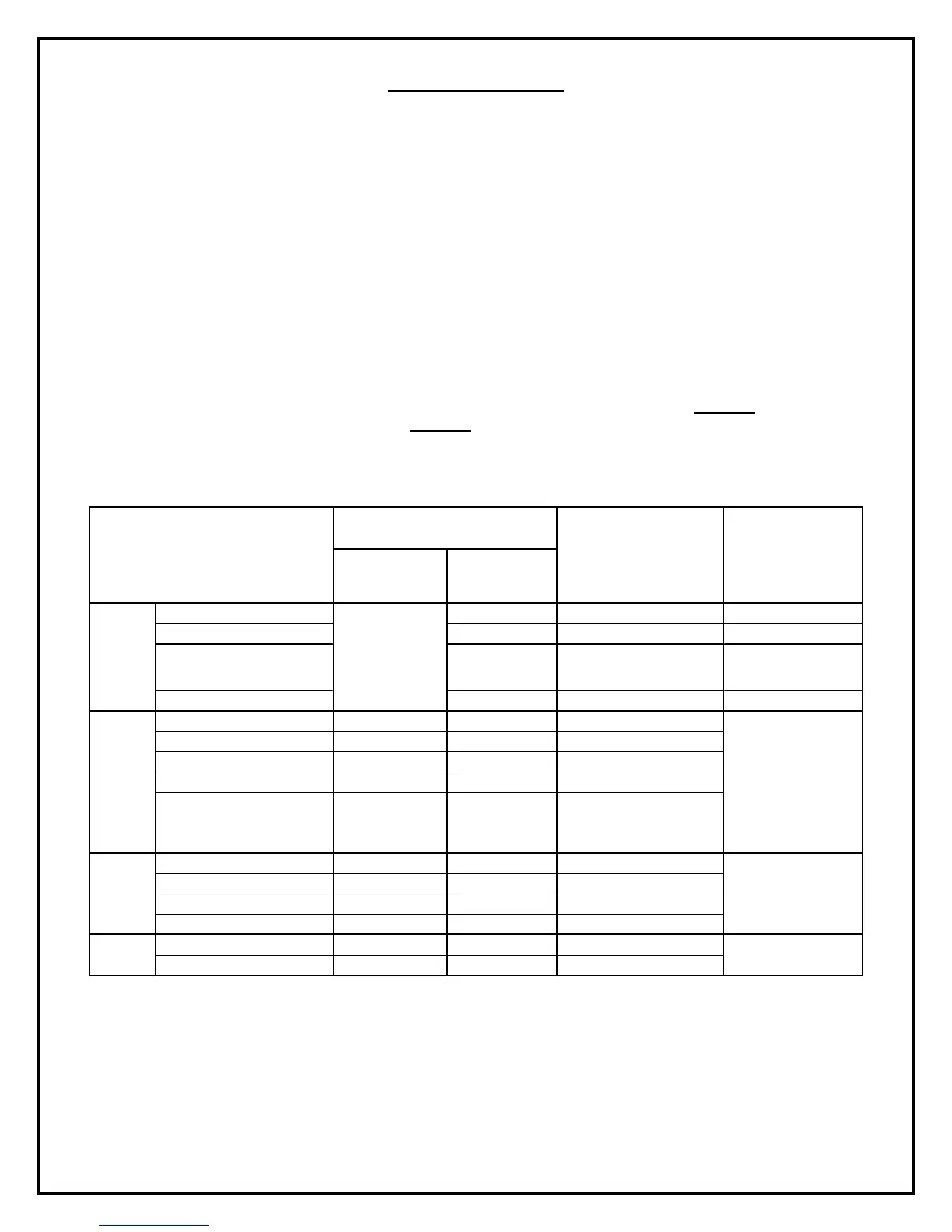

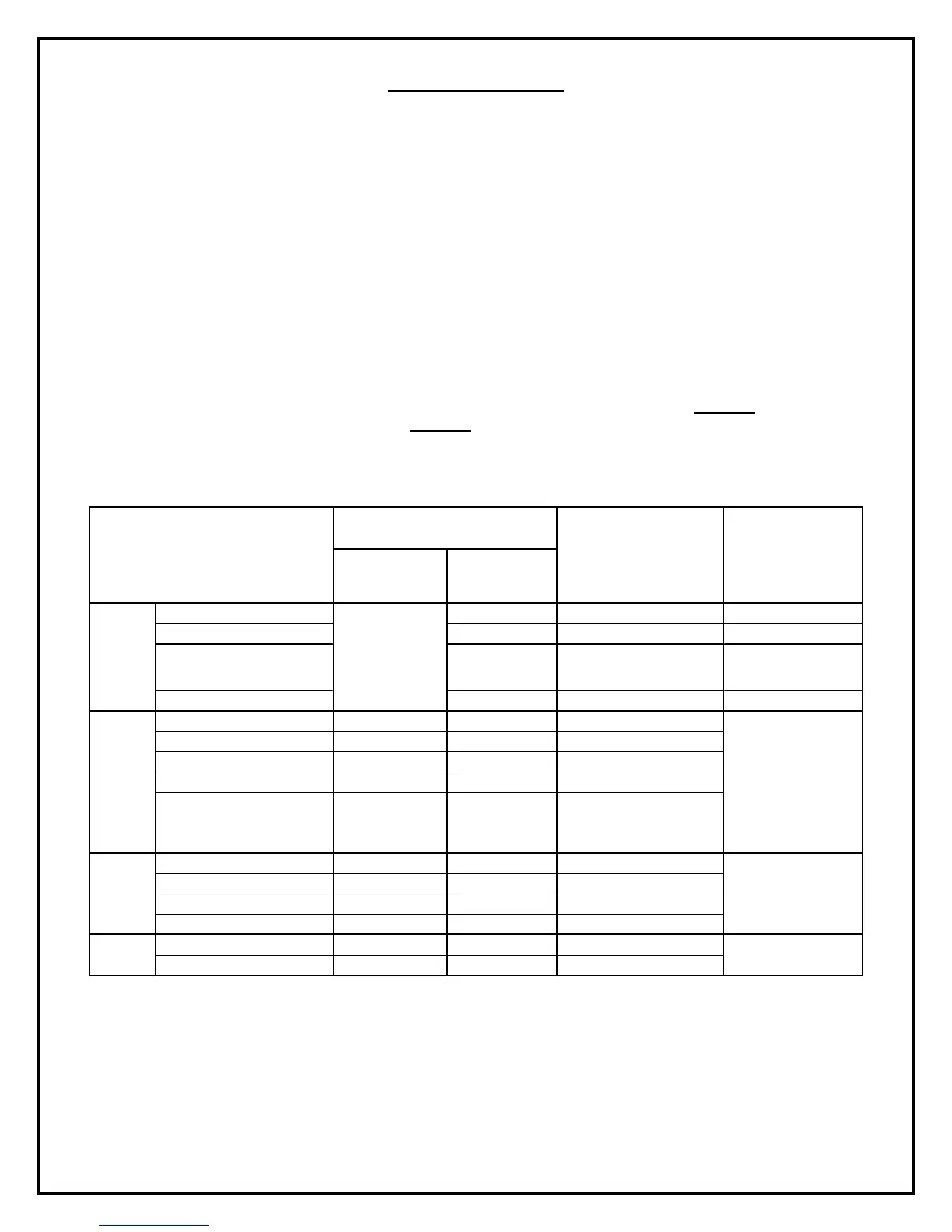

R-12 R-22, R-502

Copeland Ultra 22CC

A

A

P

Mobil EAL ARTIC 22 CC

AA P

ICI (Virginia KMP)

Emkarate RL 32CF

AA P

Thermal Zone 22CC

AA P

Witco Suniso 3GS

PP PM

Texaco Capella WF32

PP PM

Calumet RO15 (Witco)

PP PM

Witco LP-200*

PP

Penreco*

Sontex 200-LT

Shritene

PP

Copeland Ultra 200

AA PM

Shreve Zerol 200 TD

AA PM

Soltex AB200A

AA PM

Thermal Zone 200

AA PM

Shell 22-12

AA P

Witco R-195-0

AA P

Legend P = Preferred Lubricant Choice M = Mixture of Mineral Oil and AlkylBenzene

* BR, QR and Scroll A/C applications

(AB) with 50 % AB.

NOT

ACCEPTABLE

POE's

A/B M/O

Mix

NOT

ACCEPTABLE

A = Acceptable Alternative

Refri

eration Oils - Co

eland Semi-Hermetic Reci

rocatin

Com

ressors

A/B

NOT

ACCEPTABLE

NOT

ACCEPTABLE

Mineral

Oils

Lubricant Type

Traditional Refrigerants

Interims

R-401A, R-401B, R402A,

R-408A, R409A (MP-39,

MP-66, HP-80, FX-10, FX

56)

HFC's

R-134a, R-404A, R

507, R-407C, R-

410A

Loading...

Loading...