with a new one.

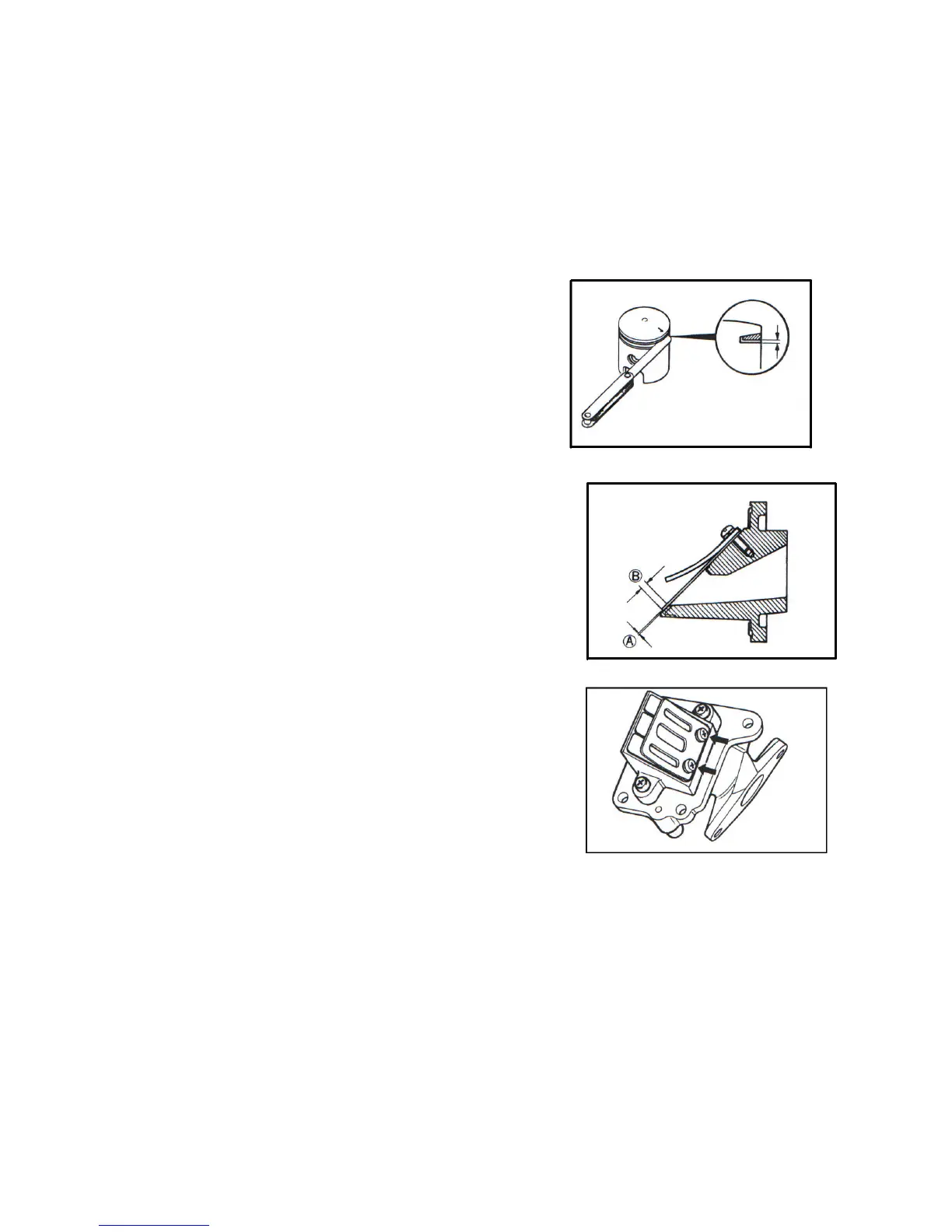

The end gap of each ring is to be measued with the ring fitted squarely into the cylidner bore and

held at the least worn part near the cylidner bottom, as shown in the illustration.

Service limit:0.75mm(0.030in)

As the piston ring wears, its end gap increases reducing

reducing engine power output becaust of the resultant blow

by through the enlarged gap. Here lies the importance of

using piston rings with end gaps with the limit. Measure the

piston ring free end gap to check the spring tension.

service limit:3.6mm(0.14in)

Fix the piston ring in the piston ring groove, measure

the ring side clearance with the thicknes gauge while matching

the sliding surface of piston and ring.

Standard clearance

1st:

::

:0.04-0.06mm(0.0016-0.0024in)

2nd:0.02-0.04mm(0.0008-0.0016in)

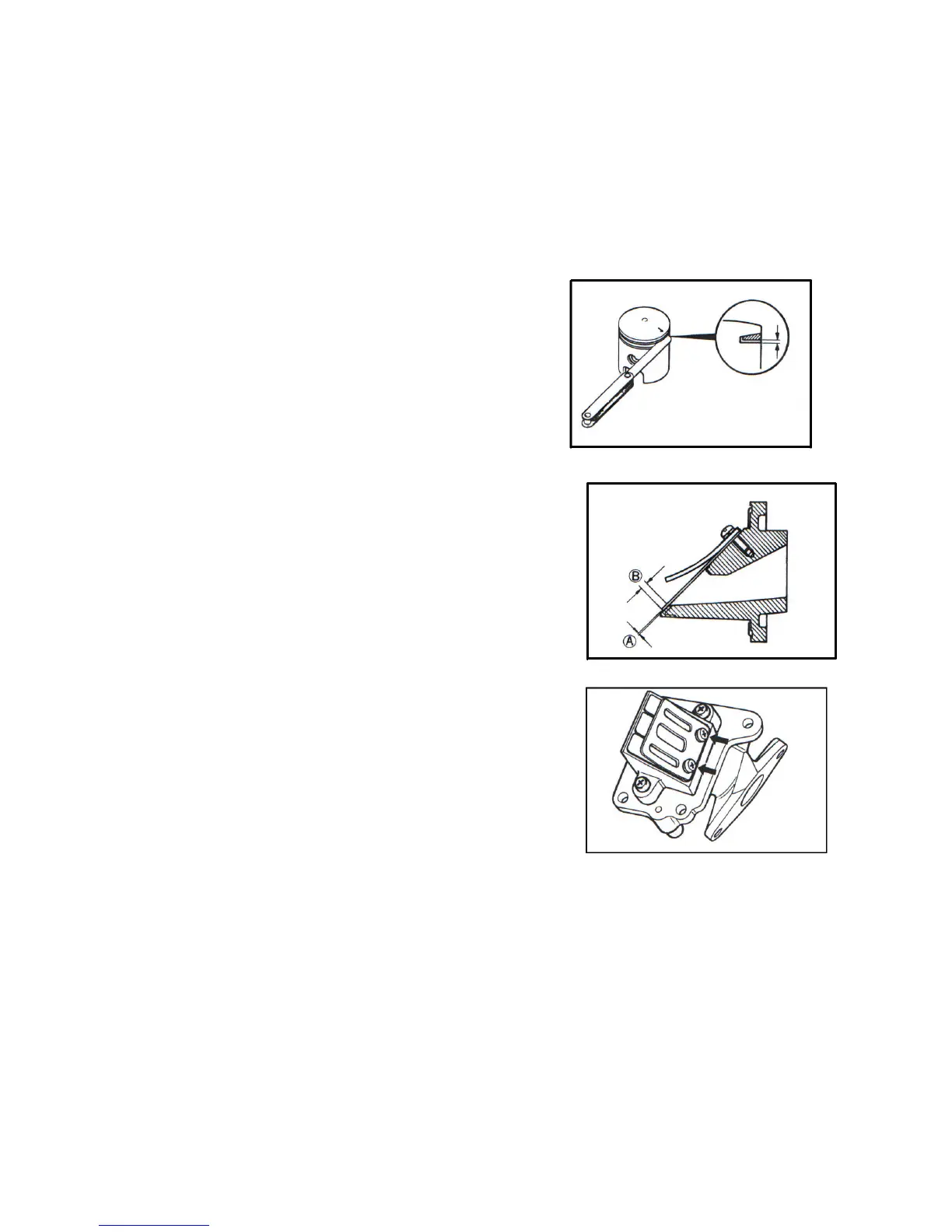

Reed vakve

Check the clearance A between reed valve and its seat

and the dimension B. If the clearance A is noted to exceed

0.2mm, replace the reed valve assembly. The dimension B is at

least 1mm.

Loading...

Loading...