4-6 Troubleshooting

Analog circuits

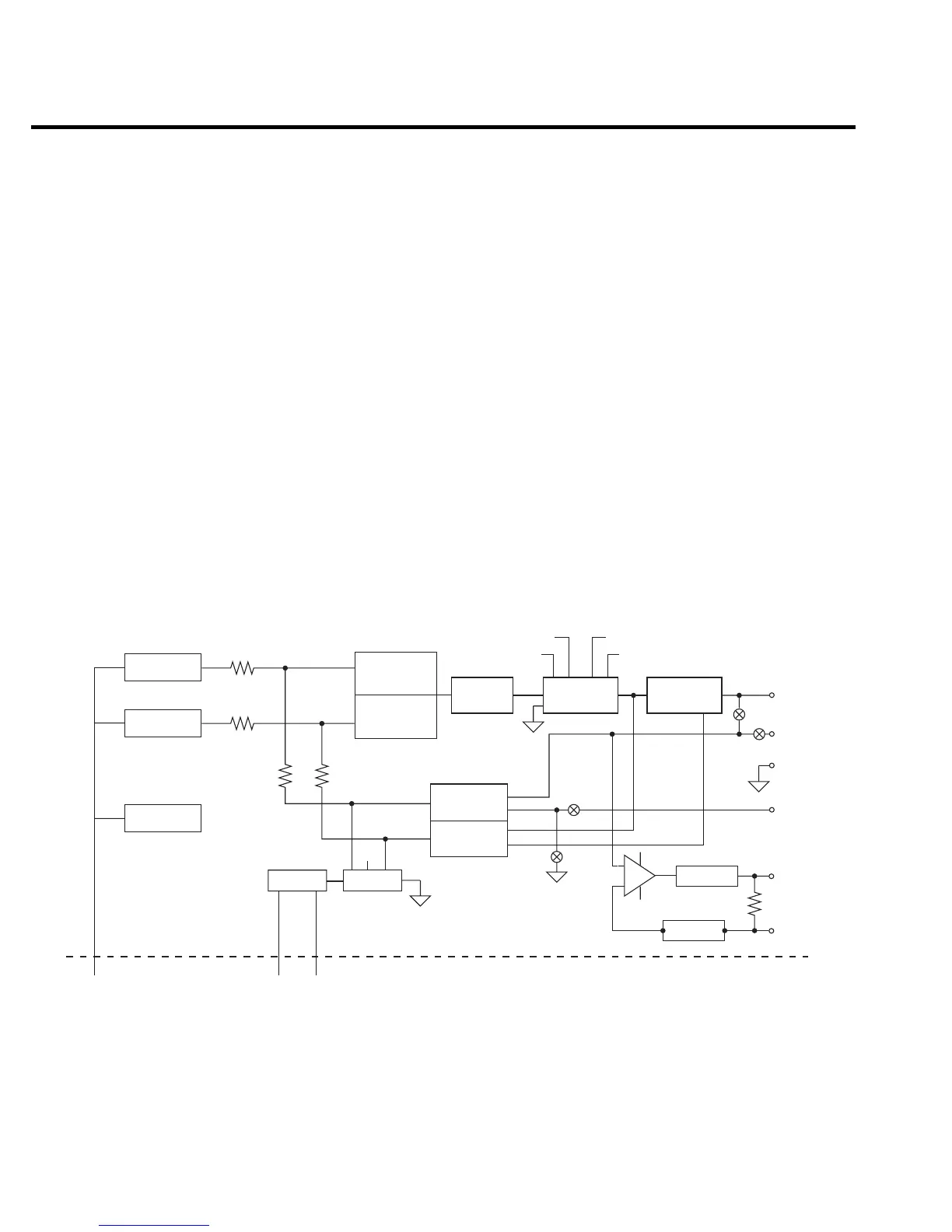

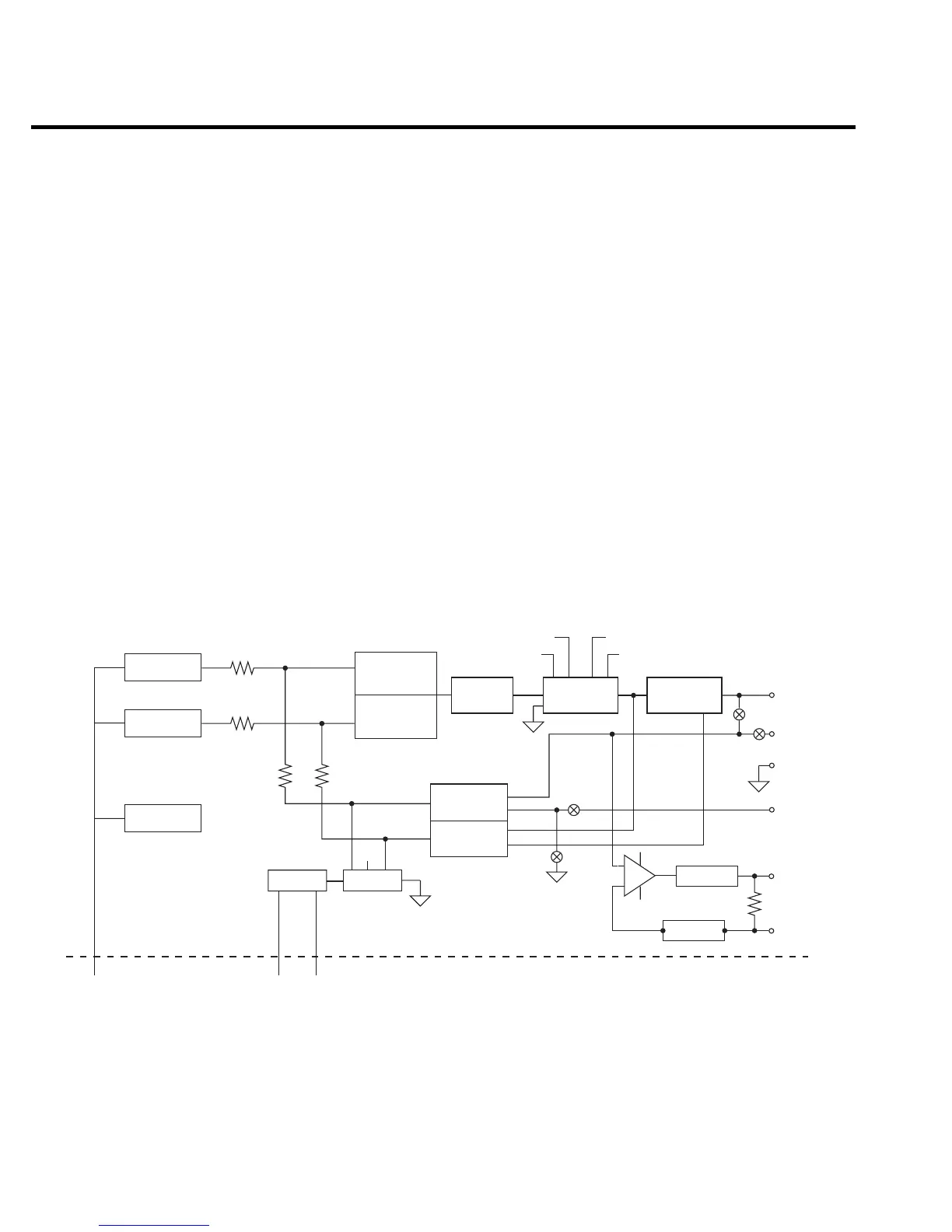

Figure 4-2 shows a block diagram of the analog circuits.

D/A converters control the programmed voltage and current, or voltage compliance and current

compliance. Each DAC has two ranges, a 10V full-scale output or a 1V full-scale output. The

DAC outputs are fed to the summing node, FB. Either the V DAC or the I DAC has the ability to

control the main loop. If the unit is set for SV (source voltage), it will source voltage until the com

-

pliance current is reached (as determined by the I DAC setting), and the current loop will override

the voltage loop. If, however, the unit is set for SI (source current), it will source current until the

compliance voltage is reached (as determined by the V DAC setting), and the voltage loop will

override the current loop. A priority bit in the Vclamp/I clamp circuit controls these functions.

The error amplifier adds open-loop gain and slew-rate control to the system to assure accu-

racy and provide a controllable signal for the output stage, which provides the necessary voltage

and current gain to drive the output. Sense resistors in the HI output lead provide output current

sensing, and a separate sense resistor is used for each current range. The 1A and 3A ranges use

0.2V full-scale for a full-range output, while all other ranges use 2V output for full-scale current.

Voltage feedback is routed either internally or externally.

V DAC

I DAC

Control

O

+

-

V Clamp

I Clamp

Error

Amp

Output

Stage

Sense

Resistors

FB

VFB

IFB

VFB

IFB

MUX

+7

S

A/D

-150

-42

+42

+150

Output

HI

S+

O

Output

LO

S-

O

Remote

Protection

Protection

Guard

Out

Guard

Sense

Figure 4-2

Analog circuitry block diagram

There are four voltage ranges: 0.2V, 2V, 20V, and 100V. The feedback gain changes only for

the 20V and 100V ranges, resulting in three unique feedback gain values. A multiplexer directs

the voltage feedback, current feedback, reference, or ground signal to the A/D converter. An

opto-isolated interface provides control signals for both DACs, analog circuit control, and A/D

converter communication to the digital section.

Loading...

Loading...