EN

FE 32

Enjoy using FE welding gun!

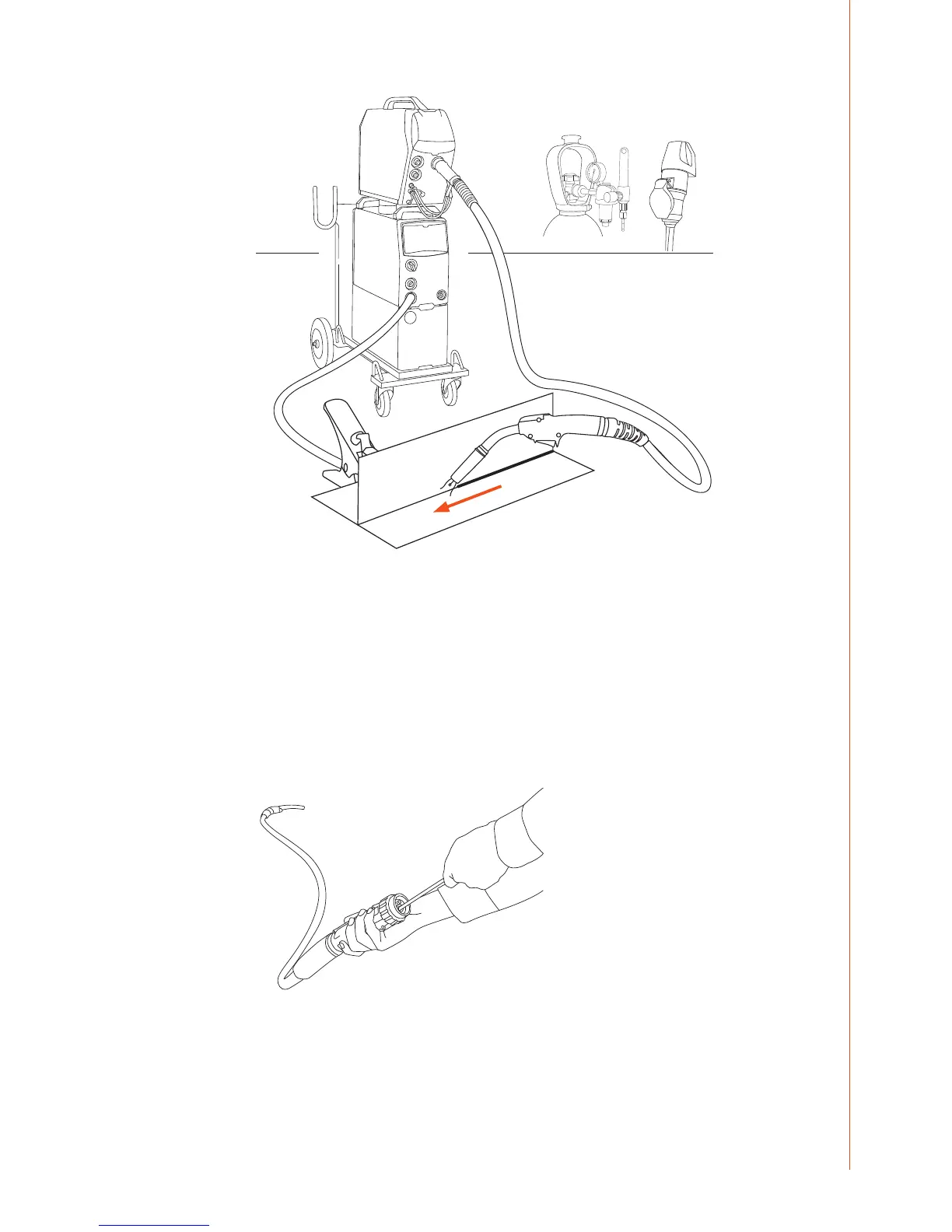

3. USE AND MAINTENANCE

The amount of use and working environment should be taken into consideration when

planning the maintenance of MIG guns. Correct use and preventive maintenance will help

ensure trouble-free operation and excellent gun life.

Due to high temperatures and wear, the welding end of the MIG gun requires the most

frequent maintenance. The condition of other parts, including the gun cable, should also be

checked for wear or damage.

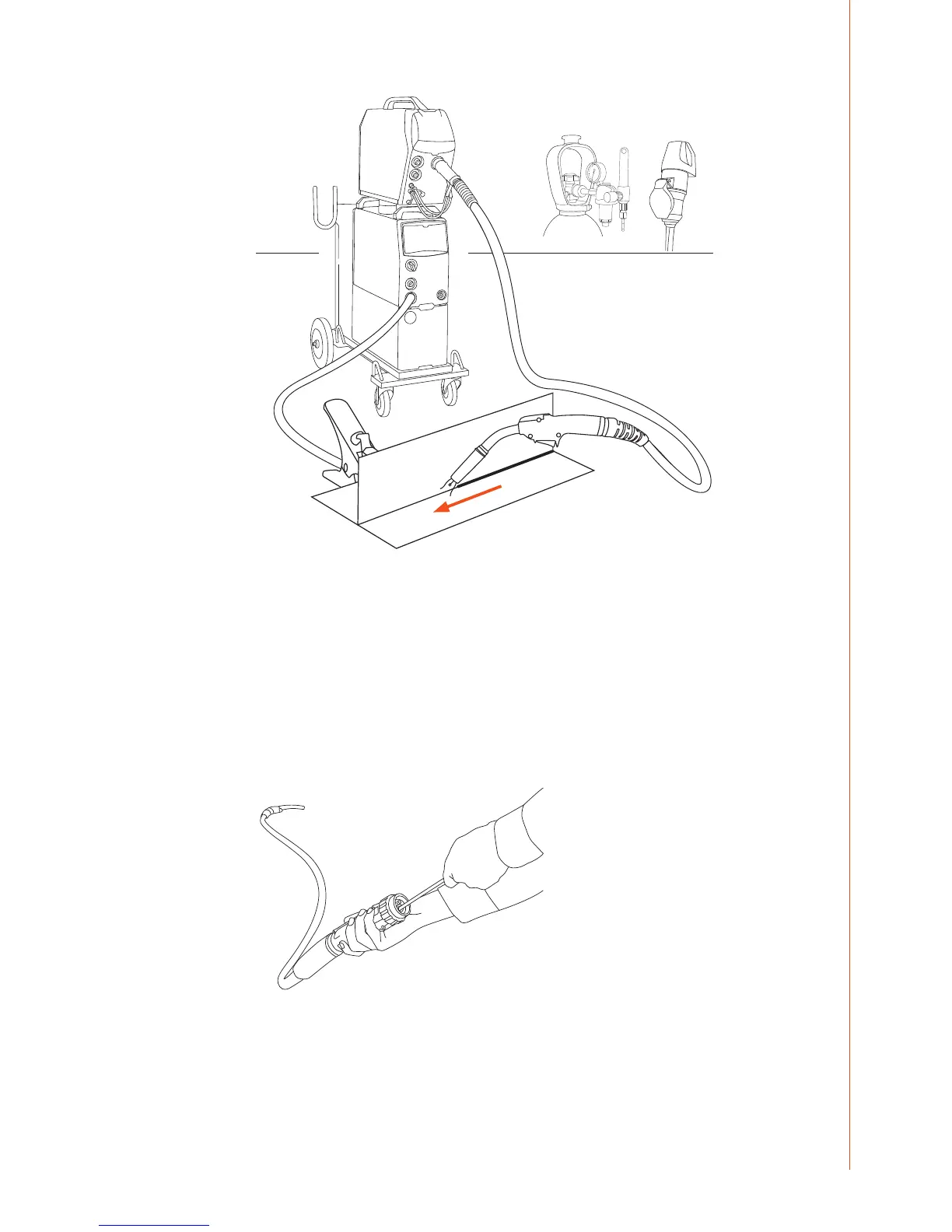

When tting new liners, lay the gun straight on a at surface.

The gun is equipped at the factory with a spiral liner for welding normal steel wire. Before

connecting the gun to the welding machine, make sure that the liner type meets the

recommendations for the welding ller wire to be used.

7

© Kemppi Oy / 1135

Loading...

Loading...