Port B is connected on the starboard line and Port C to the port line.

Couple the balance pipe (port A) to the compensating coupling on the helm pump. This may

need running some distance, and should rise gradually with no down turns. This line can be

low pressure (35 kg/cm

2

) and preferably transparent to assist in visually clearing the system.

NOTE:

PTFE (Teflon, Fluon etc.) tape should not be used on the fitting or damage to

the system may result.

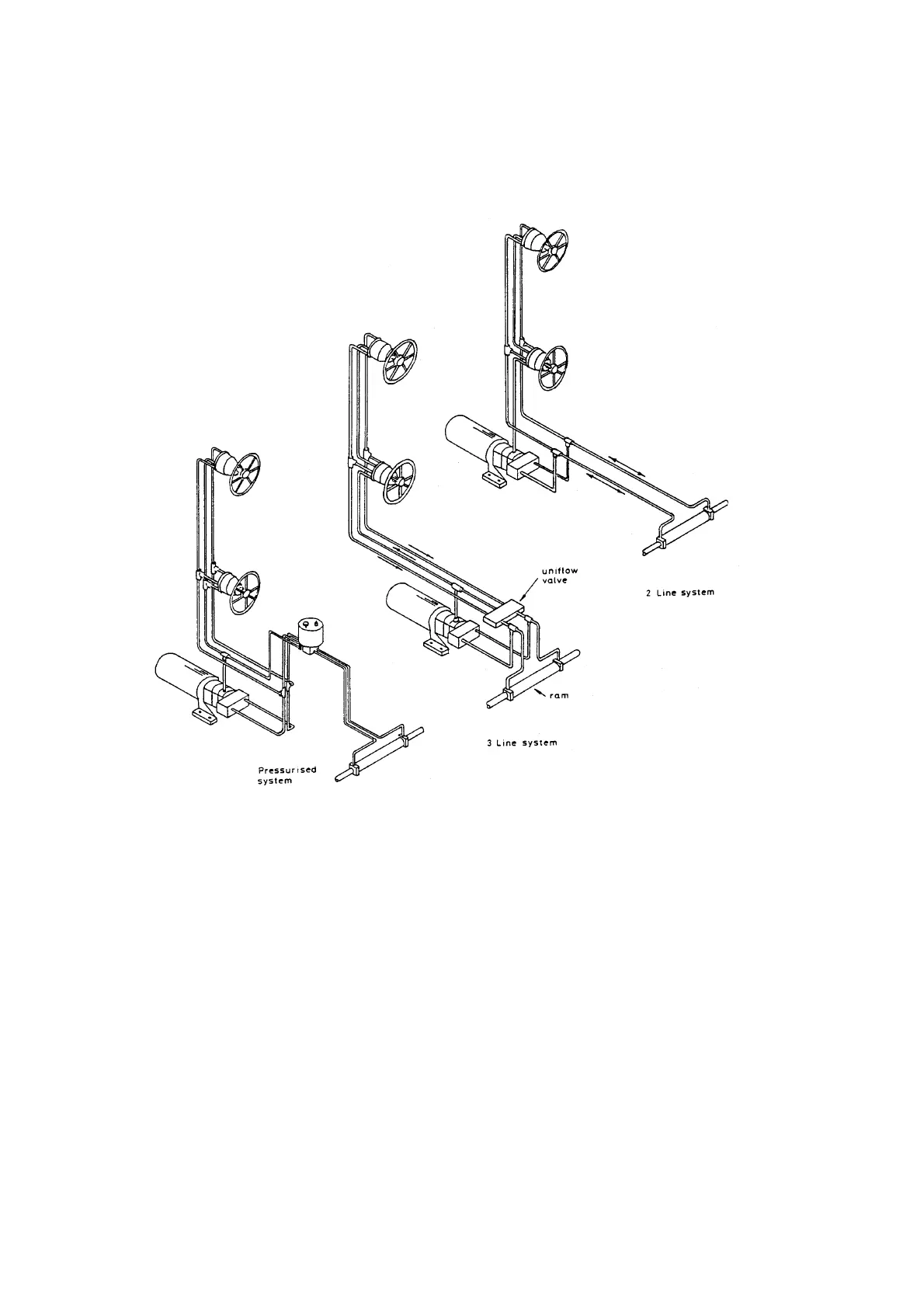

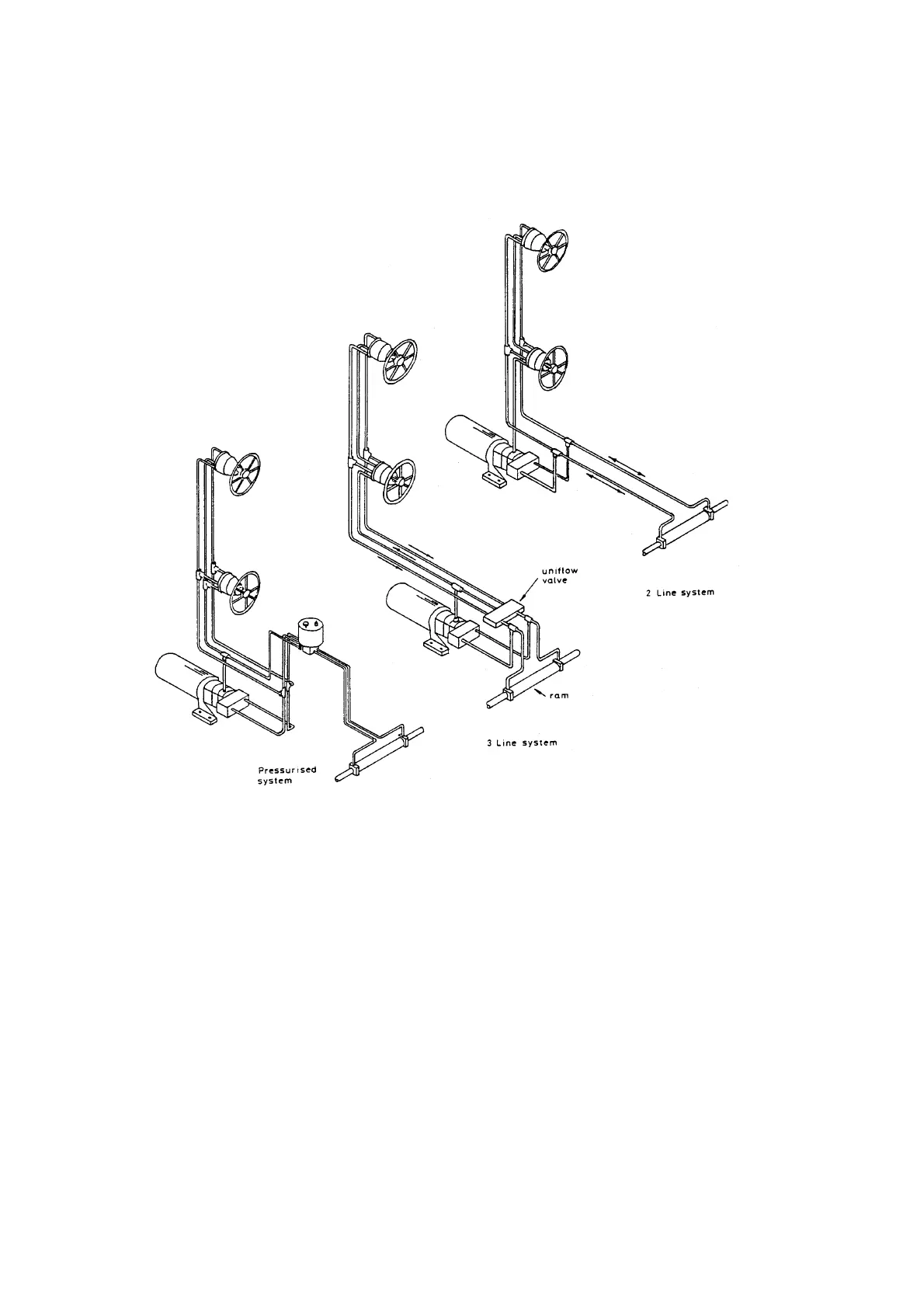

FIGURE 3

Filling the System

Make absolutely sure there is no dirt or swarft left at the joints or anywhere in the system.

Check that all unions are tight, the emergency valve (if fitted) is closed and then proceed to

refill the system, preferably with new, clean oil. The steering gear manufacturer’s own

recommendations should always be followed when deciding on the correct oil for the

system.

Take care not to enclose any air in the system. If the manufacturer’s directions are not avai-

lable proceed as follows:

Disconnect the hoses from the cylinder or cylinders and fill each cylinder at each end with

oil. Reconnect the hoses and pour oil into the helm pump until within 2 cm of the top.

Now turn the wheel slowly back and forth about two turns. Top up the helm unit as oil is pus-

hed down into the system. On no account allow the oil level to drop below the rotor which

can be seen through the top filler hole in the helm pump.

Next turn the helm as far as it will go in one direction and apply moderate pressure, then

repeat in the other direction, keeping the oil level topped up all times.

When the system will accept no more oil it may be considered full.

8 600 853 Ausgabe 06/96 Seite 6 von 8 (hypump.qxd)

Loading...

Loading...