61

KR 702- 2 / Serial no. 1910404/2008

5 Crawler tracks

The drill rig KR 702- 2 is equipped with two crawler tracks. In order to ensure a per-

fect function of the tracks, special attention to the correct track chain tension and

maintenance of the tramming gear must be paid.

Rotating component wear parts such as lower rollers, carrier rollers and Idlers

are sealed with lifetime friction seal groups and oil lubricated. Oil changes or refilling

are not necessary.

All srews have to be fastened after 50-100 hours of operation with the required

torque. We recommend to check the torque of screws once a week.

5.1 Adjusting Track Tension

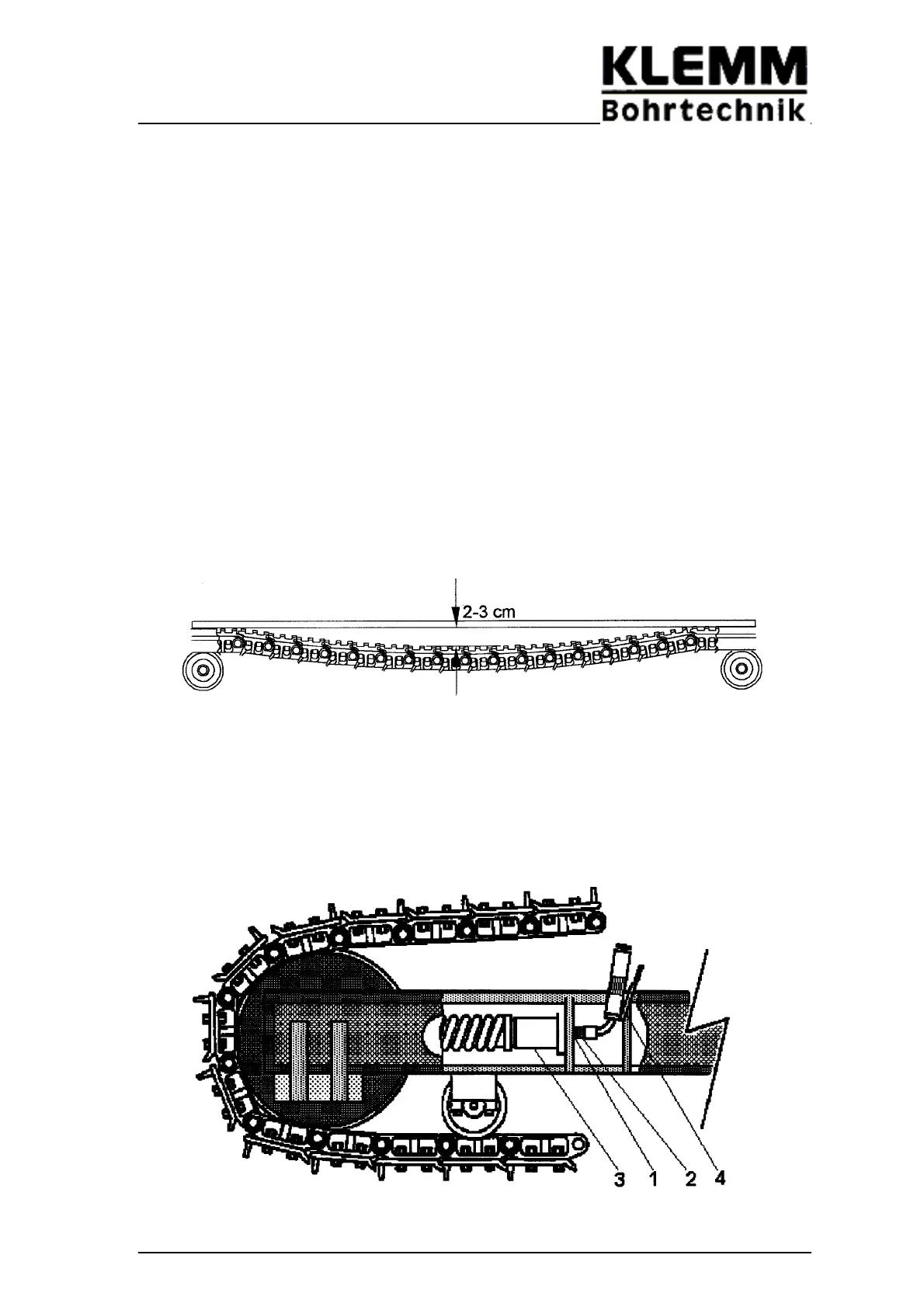

For operation of the drill rig it is important that the the chains are correctly tensioned.

A chain should be tensioned that it has approx. 2 cm slack span on 1 m.

If the distance from the supporting roller to the idler amounts to e.g. 1.5 m, then the

chain has to sag approx. 3 cm in the center.

Sketch catenary

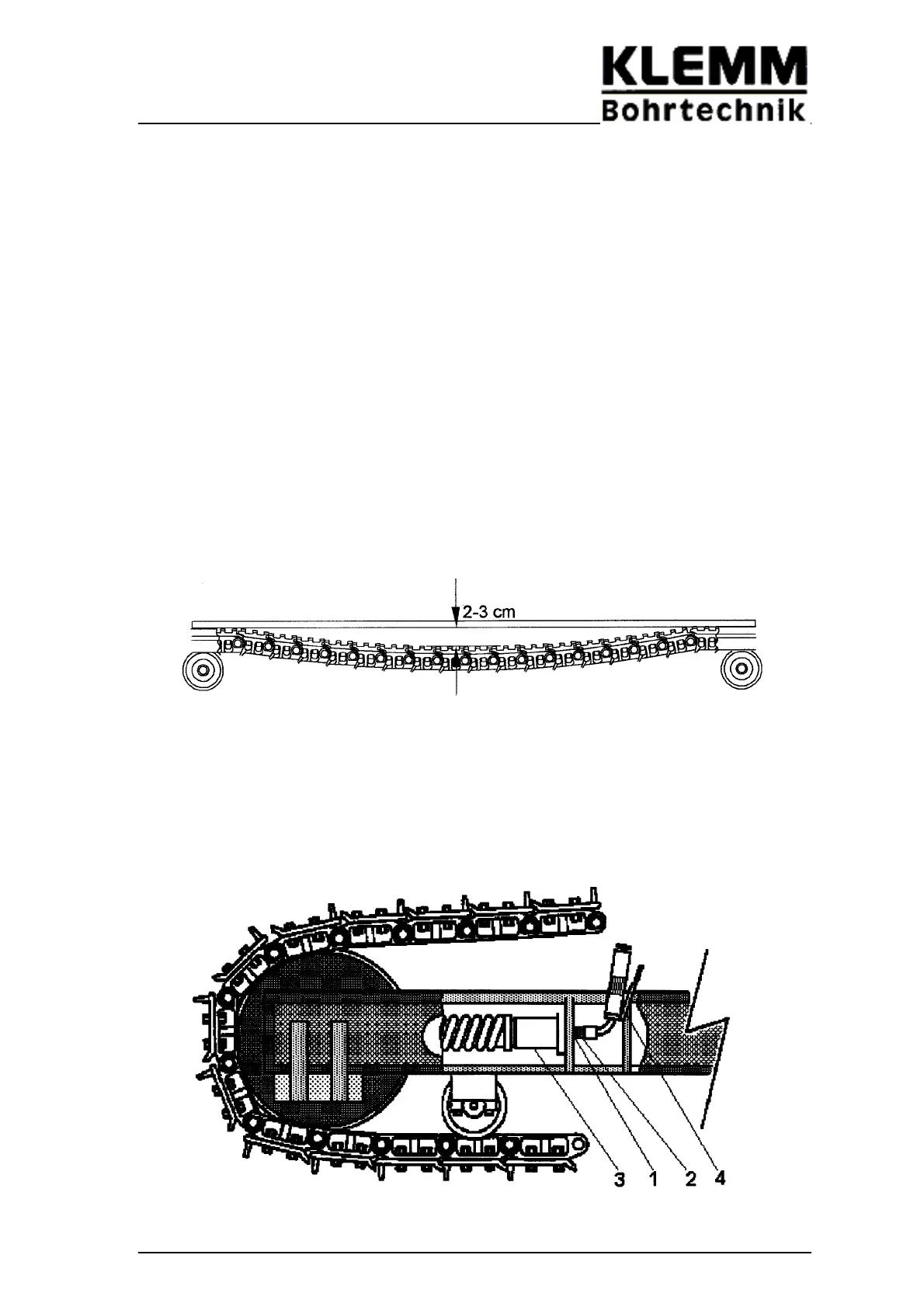

If the sagging of the chain exhibits a higher value than 3 cm, grease has to be filled

in the lubrication fitting (2) of the tensioning cylinder (3) by a grease gun (4) until the

correct tensioning value is reached.

If the track chain tension is to high, the adapter nipple (1) of the tension cylinder (3)

is to be loosened and grease must be discharged, until the correct value is reached.

Afterwards the adapter nipple is to be tightened again.

Sketch track chain tension

Loading...

Loading...