English I 53522

7 TROUBLES AND REMEDIES

Disconnect nailer from hose before servicing. When connecting the tool, it must contain no fasteners.

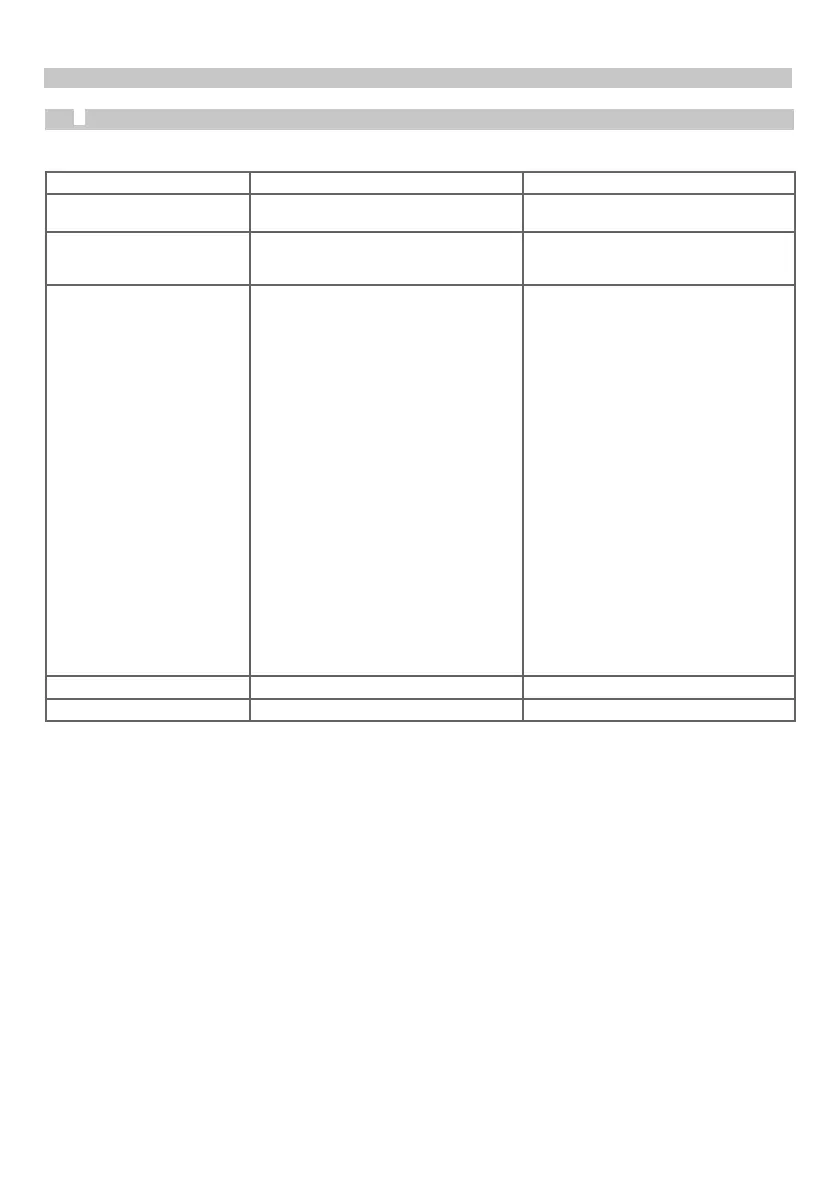

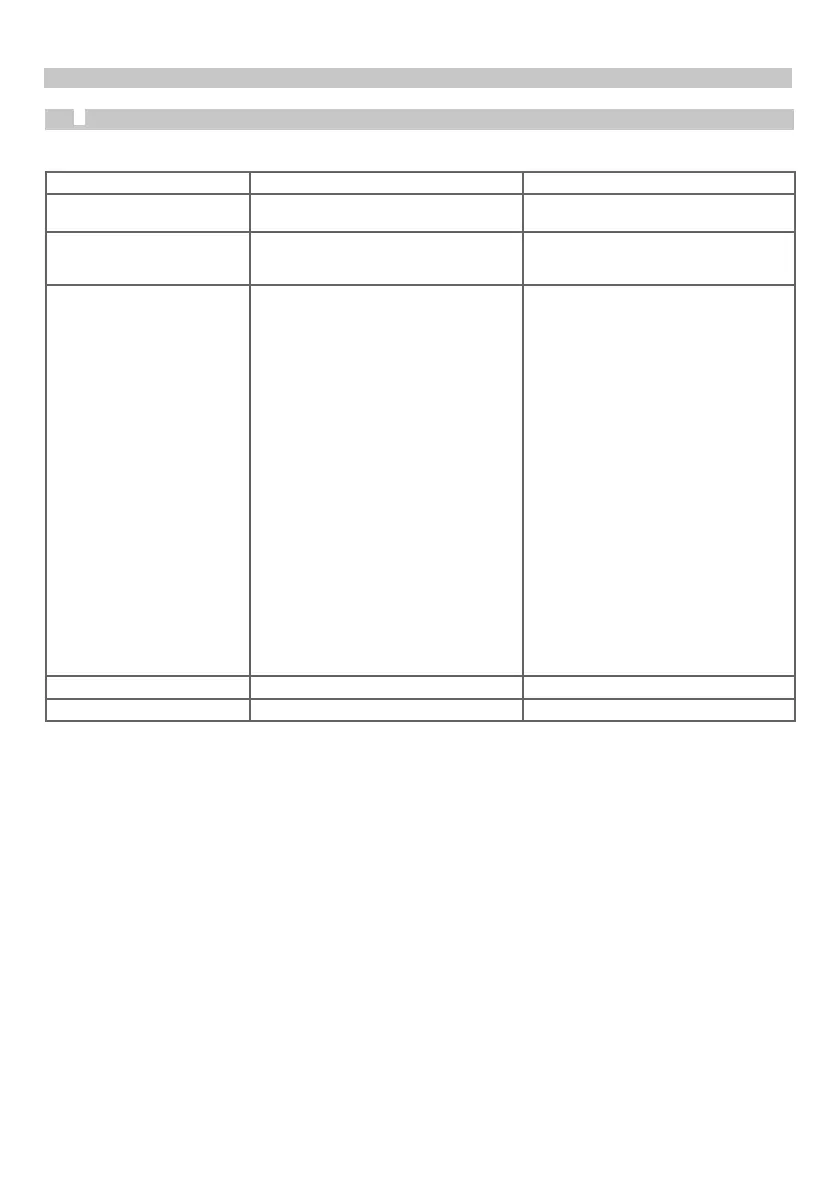

TROUBLE POSSIBLE CAUSE REMEDY

Air leaking from exhaust

port.

Parts (e, f, g) damaged or dirty. Clean or replace parts.

Blow does not take place. Control parts move with difficulty

after long term storage.

Increase air pressure and make some

trial blows. Then reduce air pressure

immediatel .

Idle impact or nails are not

fully driven in.

Bushing (p) damaged.

Tool exhausts considerably in the

lowest position of the piston, O-ring

(t), bumper (v), worn or damaged. No

backstroke.

The piston (r) does not return to the

upper position.

Tool without sufficient lubrication.

Air pressure too low.

Connection hose too long. Diameter

reduced in the air line or in the

maintenance unit (fall of pressure).

Piston completely (r) damaged.

Exchange bushing, grease bushing

and driver.

Replace damaged parts.

Have tool checked at service station.

Clean the interior pieces, grease the

counter surfaces of the O-rings and

the surface of the cylinder. Check the

lubricator.

Adjust to correct air pressure (min. 5

bar / 0.5 MPa).

Investigate and correct trouble.

Replace piston. At the same time

check bumper (v) for wear.

Nailer operates too slowly. Control parts frozen-up. Check operation of water separator.

Set of wear-and-tear parts Code No. 73 2702

During repair replacement of parts the special grease (code no. 68 3868) must be applied to the surface of

the cylinder and the counter surfaces of the O-rings.

KMR

Loading...

Loading...