TP-6551 2/1428 Section 3 Scheduled Maintenance

Note: Use soft, distilled, or demineralized water when

mixing coolant.

Note: Do not mix extended- or long-life coolants and

conventional (green) coolants.

Note: Do not mix different types and/or colors of

coolants.

Note: Consult the engine manufacturer’s operation

manual for additional engine coolant

specifications.

4. Replace the radiator’s pressure cap.

5. Operate the engine until the thermostat opens and

the radiator upper hose becomes hot.

6. Stop the engine and allow it to cool.

7. Remove the radiator’s pressure cap.

8. Add coolant to the radiator to just below the

overflow tube on the filler neck.

9. Replace the radiator’s pressure cap.

10. Maintain the coolant level in the coolant overflow

bottle between the High and Low markings.

Note: Periodically check the coolant level by removing

the radiator’s pressure cap. Do not rely solely on

the level in the coolant overflow bottle. Add fresh

coolant until the level is just below the overflow

tube opening.

3.7.4 Flushing and Cleaning

For optimum protection, drain, flush, and refill the cooling

system at the interval listed in the service schedule.

Flushing and Cleaning Procedure

1. Remove the pressure cap and open the radiator’s

coolant drain valve and let the system drain

completely. Remove the pressure cap to simplify

draining.

2. Drain, clean, and flush the coolant overflow bottle.

3. Flush the system with clean water.

4. Close the radiator’s coolant drain valve.

5. Fill the system with the recommended coolant.

6. Replace the pressure cap.

3.7.5 Pressure Cap

The cooling system utilizes a pressure cap to raise the

boiling point of the coolant, enabling higher operating

temperatures. If the cap leaks, replace it with a cap of the

same rating.

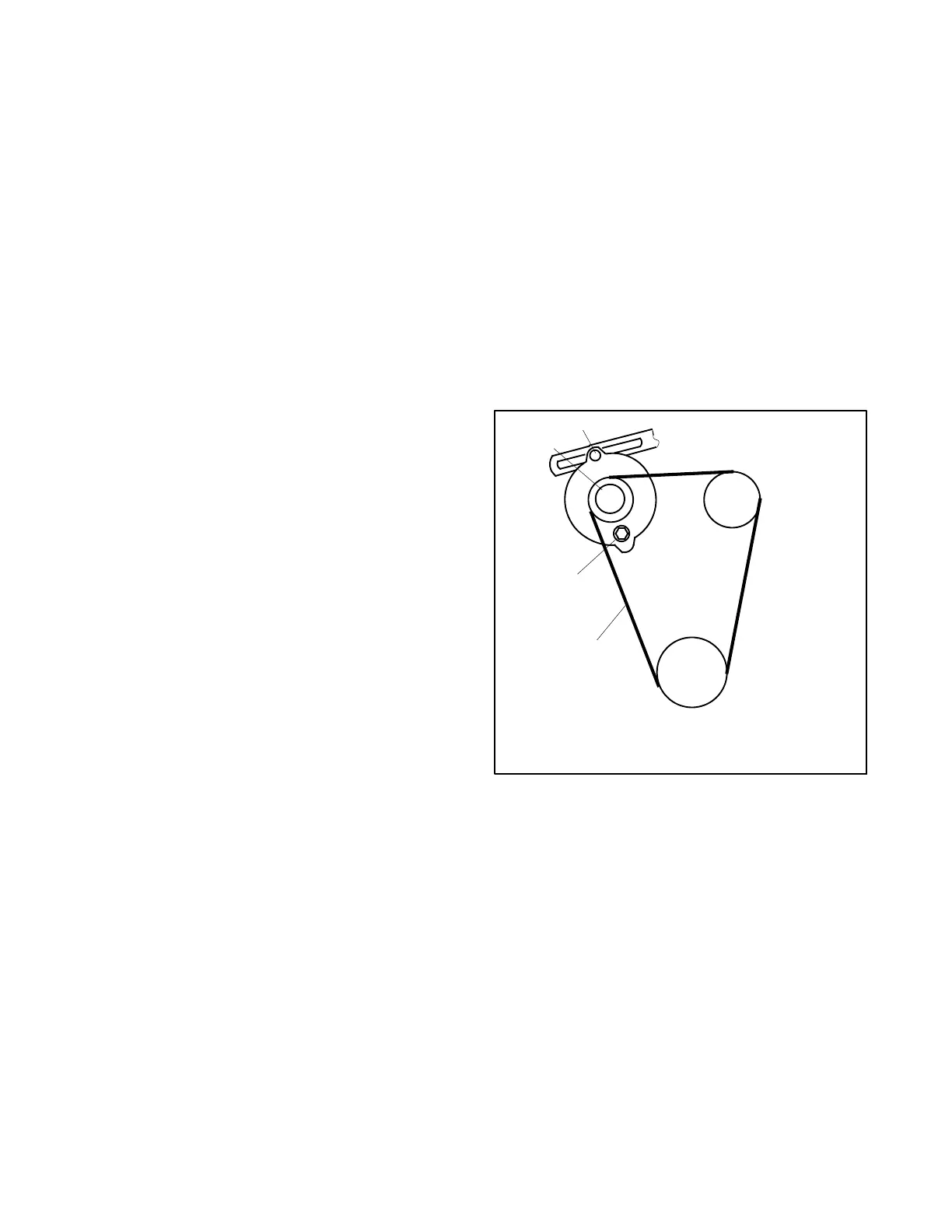

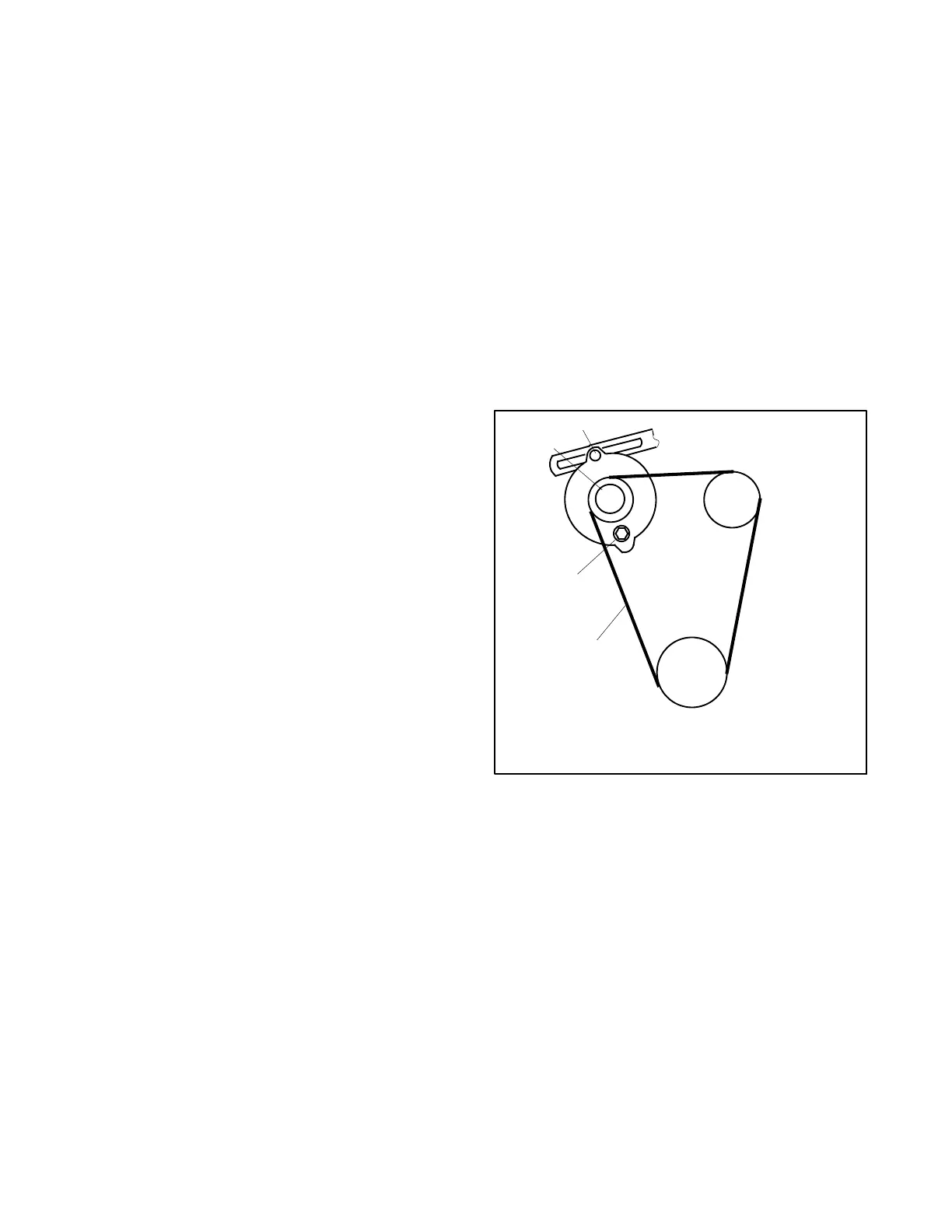

3.8 Belt Check

Check the belt tension a t the intervals specified in the

service schedule. If the tension is not within

specification, adjust as necessary using the following

procedure.

Adjust the tension of the alternator/fan belt so that the

belt can be depressed about 12.7 mm (0.5 in.) when

applying finger pressure. Use the following procedure

to adjust the belt.

1. Battery charging alternator pulley

2. Adjusting screw

3. Check the alternator belt tension here

4. Alternator pivot screw

2

1

4

3

Figure 3-11 Belt Tension

Belt Tensioning Procedure

1. Disconnect the battery, negative lead first.

2. Loosen the pivot and adjusting screws.

3. While prying the battery charging alternator

outward, tighten the adjusting screw.

4. Tighten the p ivot screw.

5. Recheck and adjust as necessary.

6. Reconnect the battery, negative lead last.

Note: Also check the fan belt for cracks or tears

and replace the belt if necessary.

Loading...

Loading...