TP-6727 10/11 Appendix 63

Appendix D Gas Fuel System Installation Planning

Determining Propane Cylinder

Quantity

Guide for Installing 100 lb. Cylinders

For continuous draws where temperatures may reach

-- 1 8 °C(--0°F). Assume the vaporization rate of 100 lb.

cylinder as approximately 50000 Btu/hr.

Number of cylinders/side = Total load in

Btu

50000

Example:

Assume total load = 200,000 Btu/hour.

Cylinders/side = 200000

= 4 cylinders/side

50000

The chart in Figure 1 shows the vaporization rate of

containers in terms of the temperature of the liquid and

the wet surface area of the container. When the

temperature is lower or if the container contains less

liquid, the vaporization rate of the container is a lower

value.

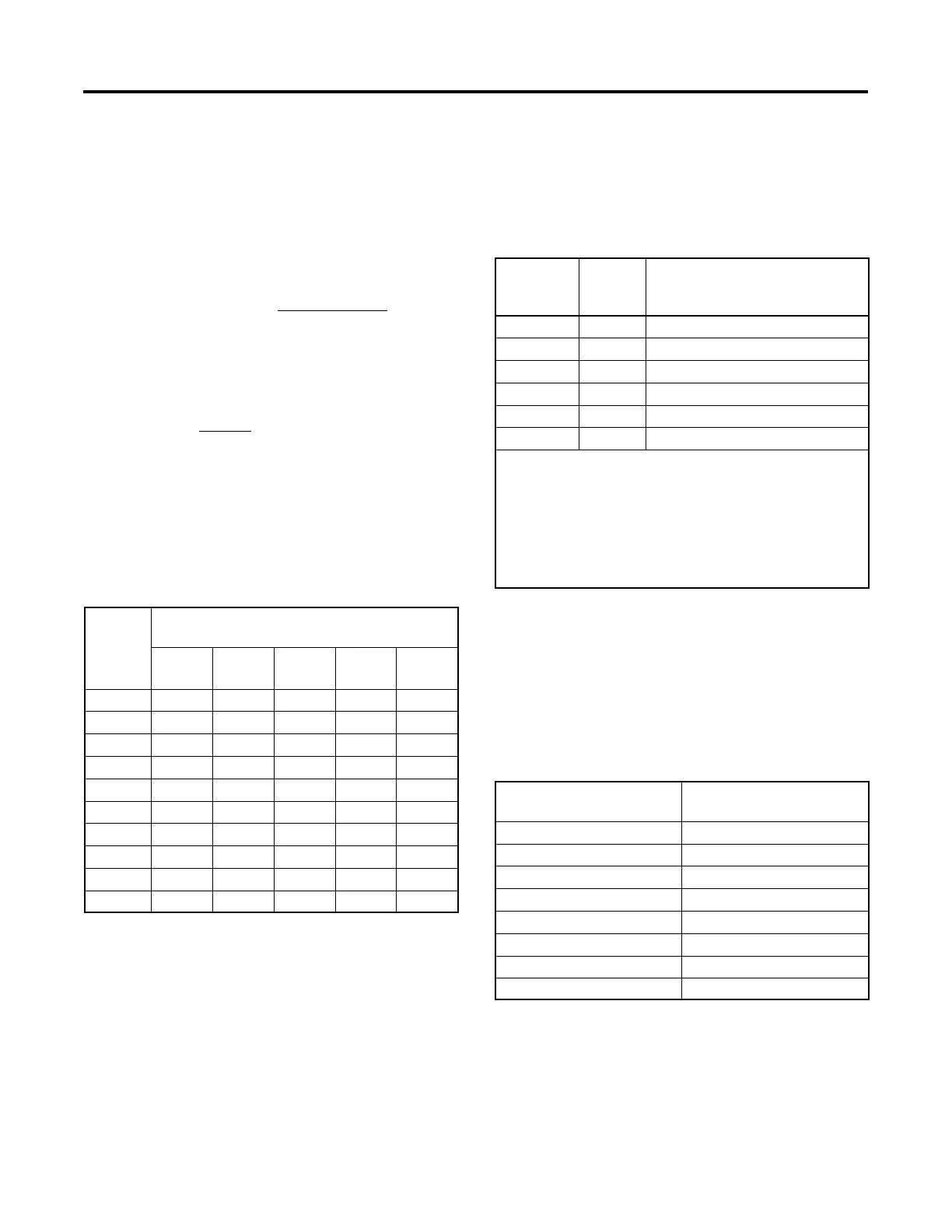

Lb. of

Propane

in Cyl.

Maximum Continuous Draw In Btu/Hour At

Various Temperatures In °C(°F)

-- 1 8 °C

(0°F)

-- 7 °C

(20°F)

4°C

(40°F)

16°C

(60°F)

21°C

(70°F)

100 113000 167000 214000 277000 300000

90 104000 152000 200000 247000 277000

80 94000 137000 180000 214000 236000

70 83000 122000 160000 199000 214000

60 75000 109000 140000 176000 192000

50 64000 94000 125000 154000 167000

40 55000 79000 105000 131000 141000

30 45000 66000 85000 107000 118000

20 36000 51000 68000 83000 92000

10 28000 38000 49000 60000 66000

Figure 1 Vaporization Rate, 100 lb. Propane

Cylinders, Approximate

Determining Propane Vaporization

Capacity

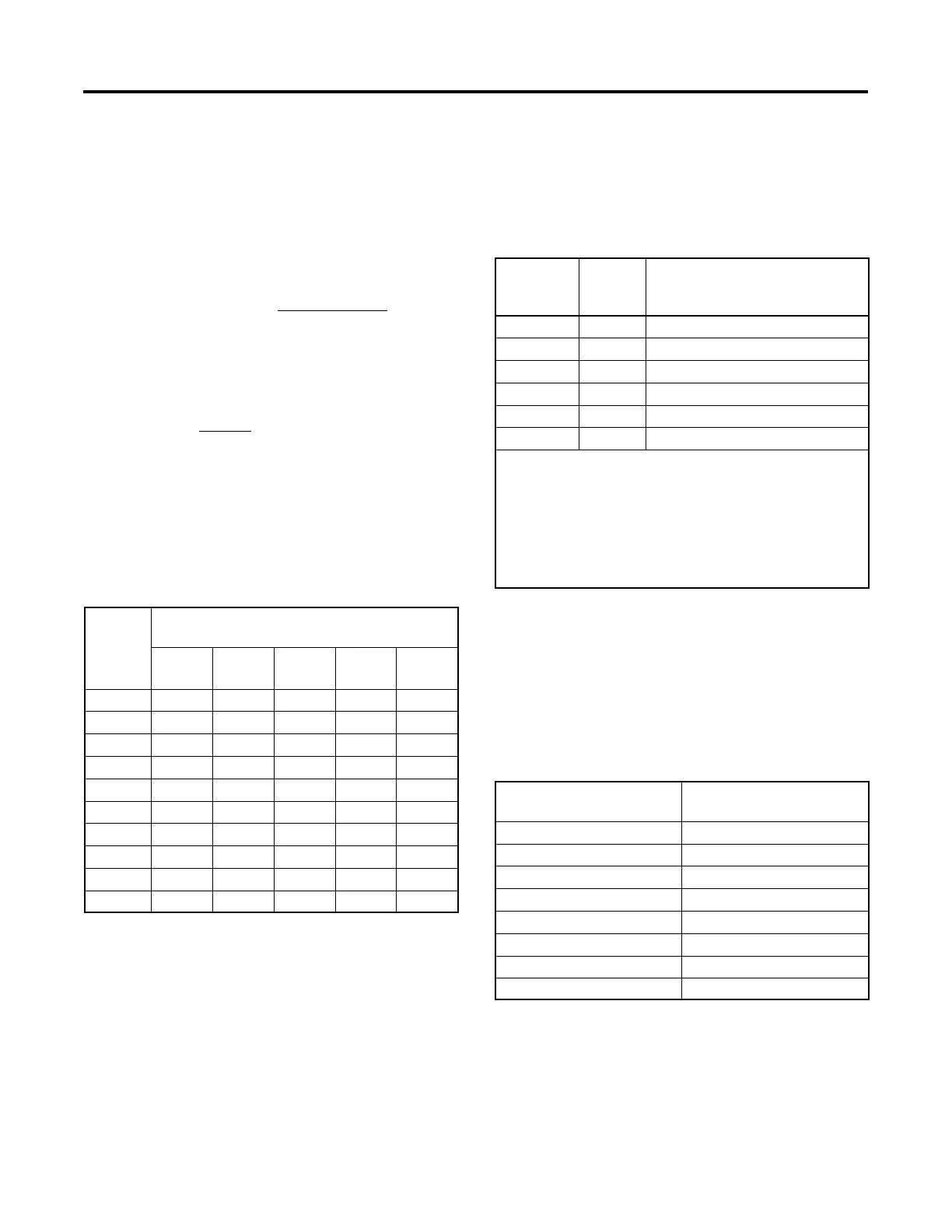

Guide for ASME LP Gas Storage

Containers

%of

Container

Filled

K

Equals

Propane* Vaporization

Capacity at --18°C(0°F) in

Btu/Hr. [

60 100 DxLx100

50 90 DxLx90

40 80 DxLx80

30 70 DxLx70

20 60 DxLx60

10 45 DxLx45

* These formulae allow for the temperature of the liquid to

refrigerate to --29°C(--20°F), producing a temperature

differential of --7°C(20°F) for the transfer of heat from the air to

the container’s wetted surface and then into the liquid. The

vapor space area of the vessel is not considered since its

effect is negligible.

[ D=outside diameter in inches

L=overall length in inches

K=constant for percent volume of liquid in container.

Figure 2 Propane Vaporization Capacity

Vaporizing Capacities for Other Air

Temperatures

Multiply the results obtained with the formulae in

Figure 2 by one of the factors in the following table for

the prevailing air temperature.

Prevailing Air

Temperature

Multiplier

-- 2 6 °C(--15°F) 0.25

-- 2 3 °C(--10°F) 0.50

-- 2 1 °C(--5°F) 0.75

-- 1 8 °C(0°F) 1.00

-- 1 5 °C(5°F) 1.25

-- 1 2 °C(10°F) 1.50

-- 2 6 °C(15°F) 1.75

-- 7 °C(20°F) 2.00

Figure 3 Propane Vaporization Temperature

Loading...

Loading...