TP-6953 7/19180 Section 10 Alternator Component Testing and Adjustment

Leads Continuity

1 and 2 3and4 —

Yes

60 and 61 61 and 62 60 and 62

1 and 3 1and4 —

No

2 and 3 2and4 —

1 and 60 1 and 61 1 and 62

2 and 60 2 and 61 2 and 62

3 and 60 3 and 61 3 and 62

4 and 60 4 and 61 4 and 62

Any stator lead and ground on stator housing or

frame laminations

No

Figure 10-12 Stator Continuity Test Results on a Good

Stator (Single Phase)

Leads Continuity

1 and 4 2and5 3and6

Yes

7 and 10 8and11 9and12

60 and 61 61 and 62 60 and 62

1 and 2 1and3 1and7

No

1 and 8 1and9 2and3

2 and 7 2and8 2and9

3 and 7 3and8 3and9

7 and 8 7and9 8and9

1 and 60 1and61 1and62

No

2 and 60 2and61 2and62

3 and 60 3and61 3and62

7 and 60 7and61 7and62

8 and 60 8and61 8and62

9 and 60 9and61 9and62

Any stator lead and ground on stator housing or

frame laminations

No

Figure 10-13 Stator Continuity Test Results on a Good

Stator (Three Phase)

5. Check the cold resistance of the stator windings by

connecting the meter leads to the stator leads as

shown in Figure 10-12 or Figure 10-13. See

Section 1, Spec if ications, for the stator resistance

values. If the stator resistance test is inconclusive,

perform a megohmmeter test on the stator as

described in the next step.

Note: Consider the stator functional if the

resistance reading (continuity) is low and

there is no evidence of shor ted windings

(heat discoloration).

Note: When taking an ohmmeter reading using

leads 60, 61, or 62, make the connection

beforethefuseifused.

Note: The stator resistance can vary directly with

increased temperature.

If any of the stator readings vary during the

previous checks, replace the stator.

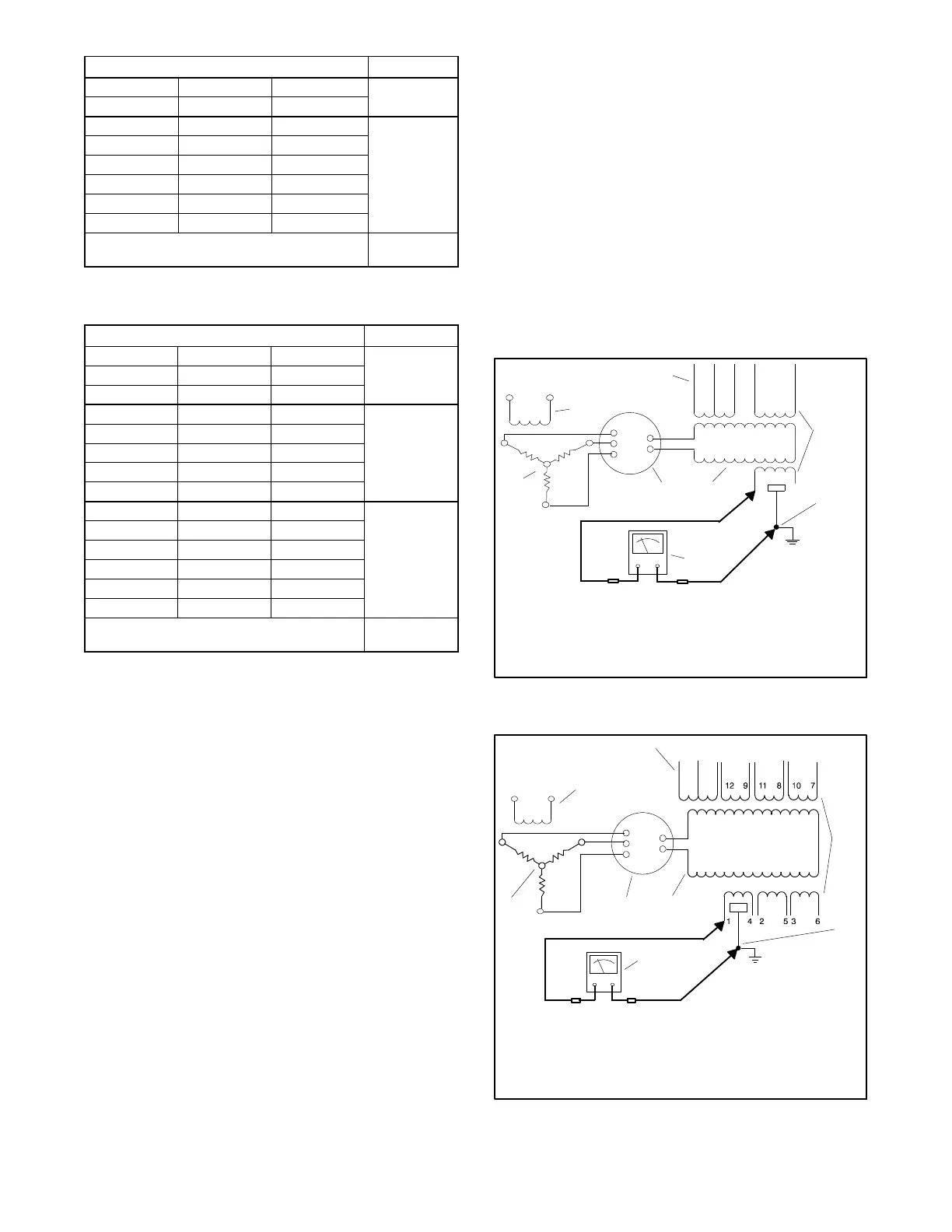

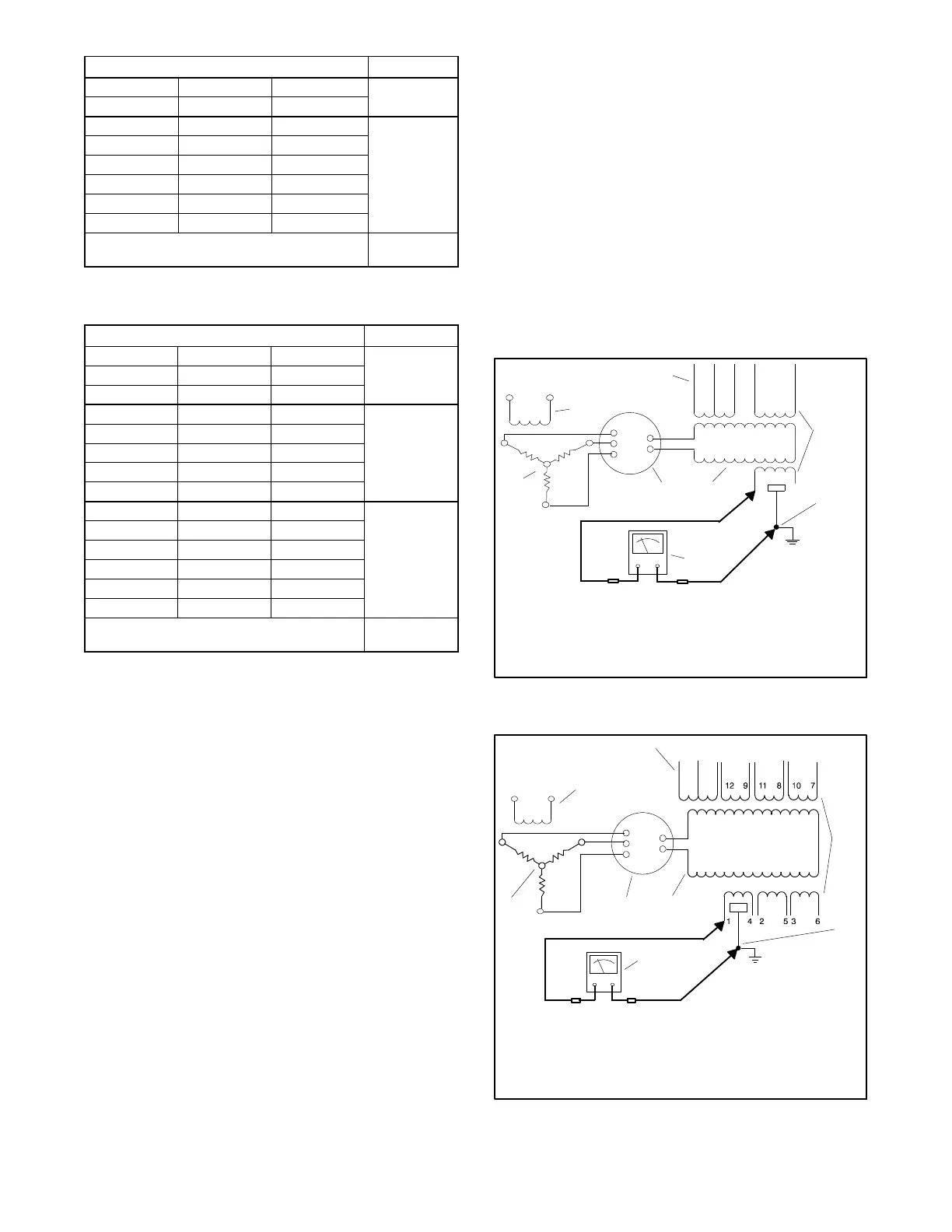

6. Check the stator for a short-to-ground condition

using a megohmmeter. See Figure 10-14 for a

single-phase megohmmeter connections and

Figure 10-15 for three-phase megohmmeter

connections.

Apply 500 volts DC to any stator lead from each

winding and the stator frame. Follow the

megohmmeter manufacturer’s instructions for

using the megohmmeter. Repeat the test on the

other leads until all of the stator windings have

been tested. A reading of 1.5 MOhms and higher

indicates the stator is functional. A reading of less

than 1.5 MOhms indicates deterioration of the

winding insulation and possible current flow to

ground; if so, repair or replace the stator.

1

5

6

7

8

9

62

61

34

12

FN FP

3

2,

4

TP-6878-3

1. Auxiliary power for exciter field and

voltage regulator

2. Voltage sensing (A, B, and NEU)

leads (208- 240 volts nominal)

3. Stator windings

4. Main field (rotor)

F+

F-

AC

AC

AC

60

5. Rectifier module

6. Frame connection

7. Megohmmeter

8. Exciter armature

9. Exciter field winding

M

Figure 10 -14 Megohmmeter Connections on Stator

(Single Phase)

62

61

TP-6878-3

1

2,

6

3

45

7

8

FN FP

9

1. Auxiliary power for exciter field and

voltage regulator

2. Voltage sensing

(A,B,C,andNEU)leads

(208- 240 volts nominal)

3. Stator windings

F+

F-

AC

AC

AC

60

4. Main field (rotor)

5. Rectifier module

6. Frame connection

7. Megohmmeter

8. Exciter armature

9. Exciter field winding

M

Figure 10 -15 Megohmmeter Connections on Stator

(Three Phase)

Loading...

Loading...