TP-5936 7/04 17Section 5 Cooling System

5.8 Anticorrosion Zinc Anode

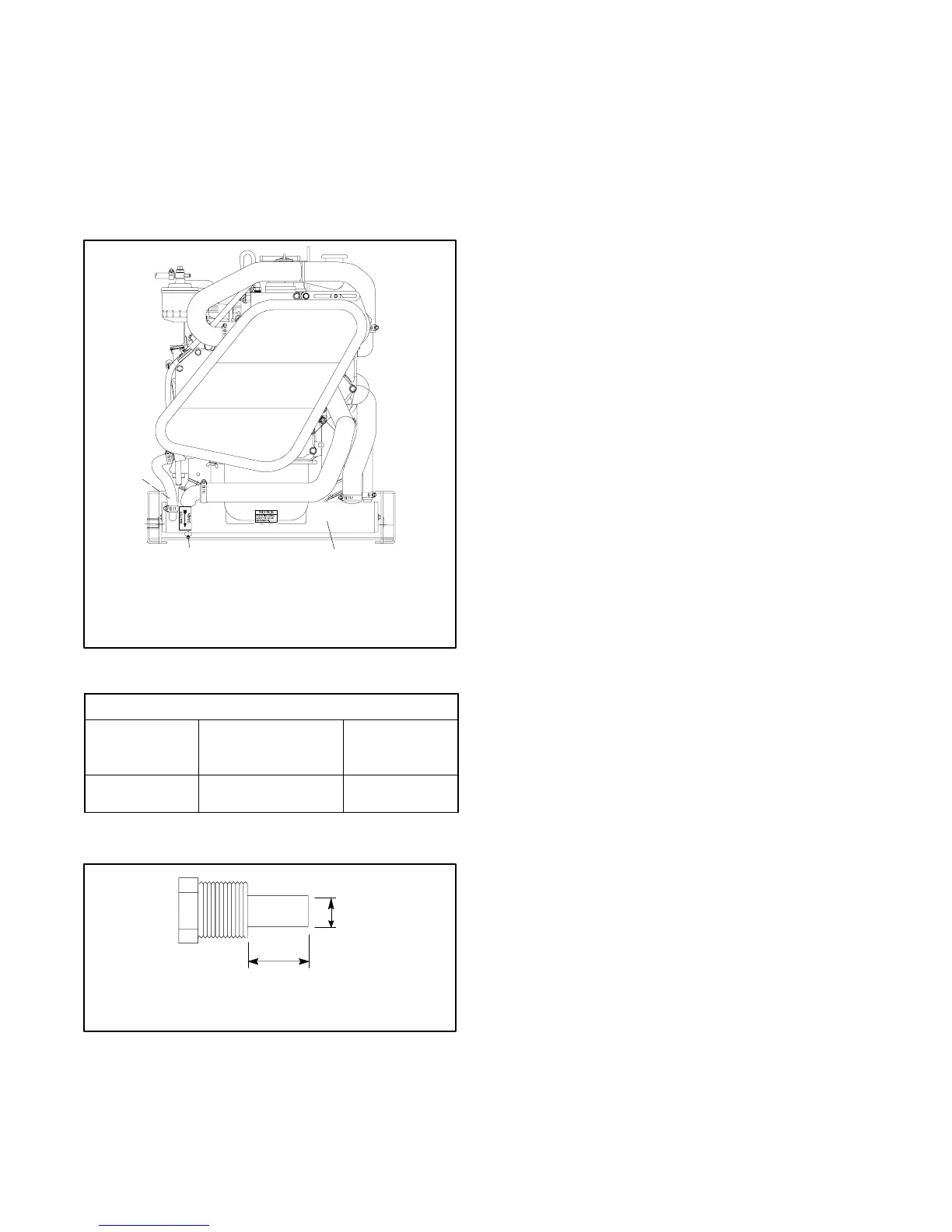

The heat exchanger contains an anticorrosion zinc

anode (plug) to prevent electrolyte corrosion by the

seawater.

Check and replace the anticorrosion zinc anode at the

intervals recommended in the service schedule. See

Figure 5-7.

GB-250000A-K

1

2

3

1. Anticorrosion zinc anode (seawater drain)

2. Heat exchanger

3. Coolant drain

Figure 5-7 Anticorrosion Zinc Anode Location

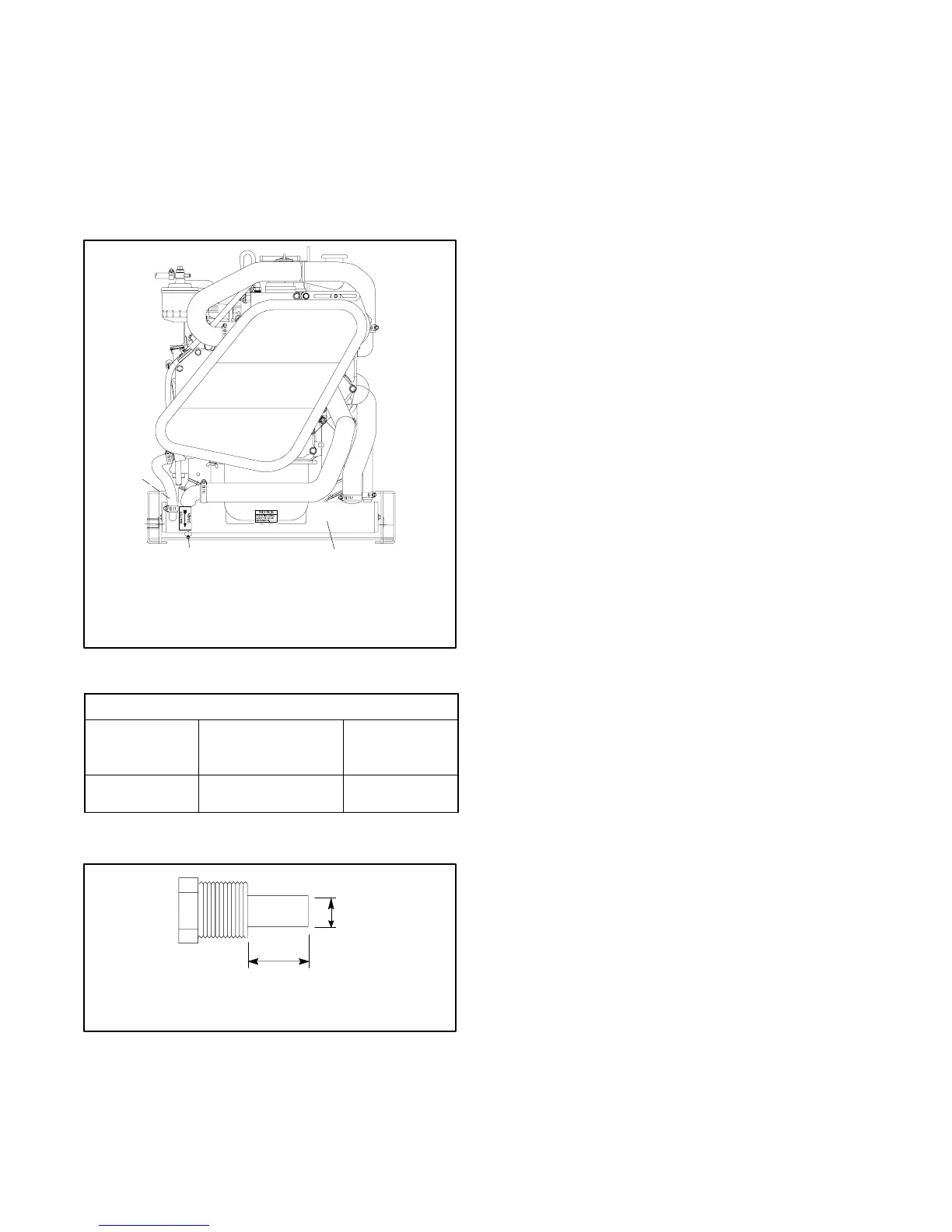

Anticorrosion Zinc Anode Replacement

Models

New Anode

Dimensions mm (in.)

Replace When

Percent of Zinc

Remaining is:

32EOZ/27EFOZ 9 (0.34) x 19 (0.75)

<50% of

length/diameter

Figure 5-8 Anticorrosion Zinc Anode Measurements

TP-5586-3

1

2

1. Diameter: 9 mm (0.34 in.)

2. Length: 19 mm (0.75 in.)

Figure 5-9 Anticorrosion Zinc Anode

Inspection and Replacement Procedure

1. Place the generator set controller start/stop switch

in the STOP position.

2. Disconnect the generator set engine starting

battery, negative (--) lead first.

3. With the generator set cooled, close the seacock,

open the engine petcock, and drain the coolant into

a suitable container.

4. Remove the anticorrosion zinc anode from the heat

exchanger. See Figure 5-7.

5. Remove the loose corrosion on the anticorrosion

zinc anode. Replace the anode according to

Figure 5-8 and Figure 5-9.

6. Apply pipe sealant suitable for marine applications

to the threads of the anticorrosion zinc anode

(plug) and install the anode in the heat exchanger.

7. Close the engine petcock and open the seacock.

8. Refill the cooling system.

9. Reconnect the generator set engine starting

battery, negative (--) lead last.

10. Start the generator set and check for leaks at the

anticorrosion zinc anode location. The pump is

running if cooling water flows from the exhaust

outlet. If water is not being discharged at the

exhaust outlet, see the Prestart Checklist,

Seawater Pump Priming, in the operation manual.

Loading...

Loading...