TP-6137 5/0322 Section 5 Fuel System

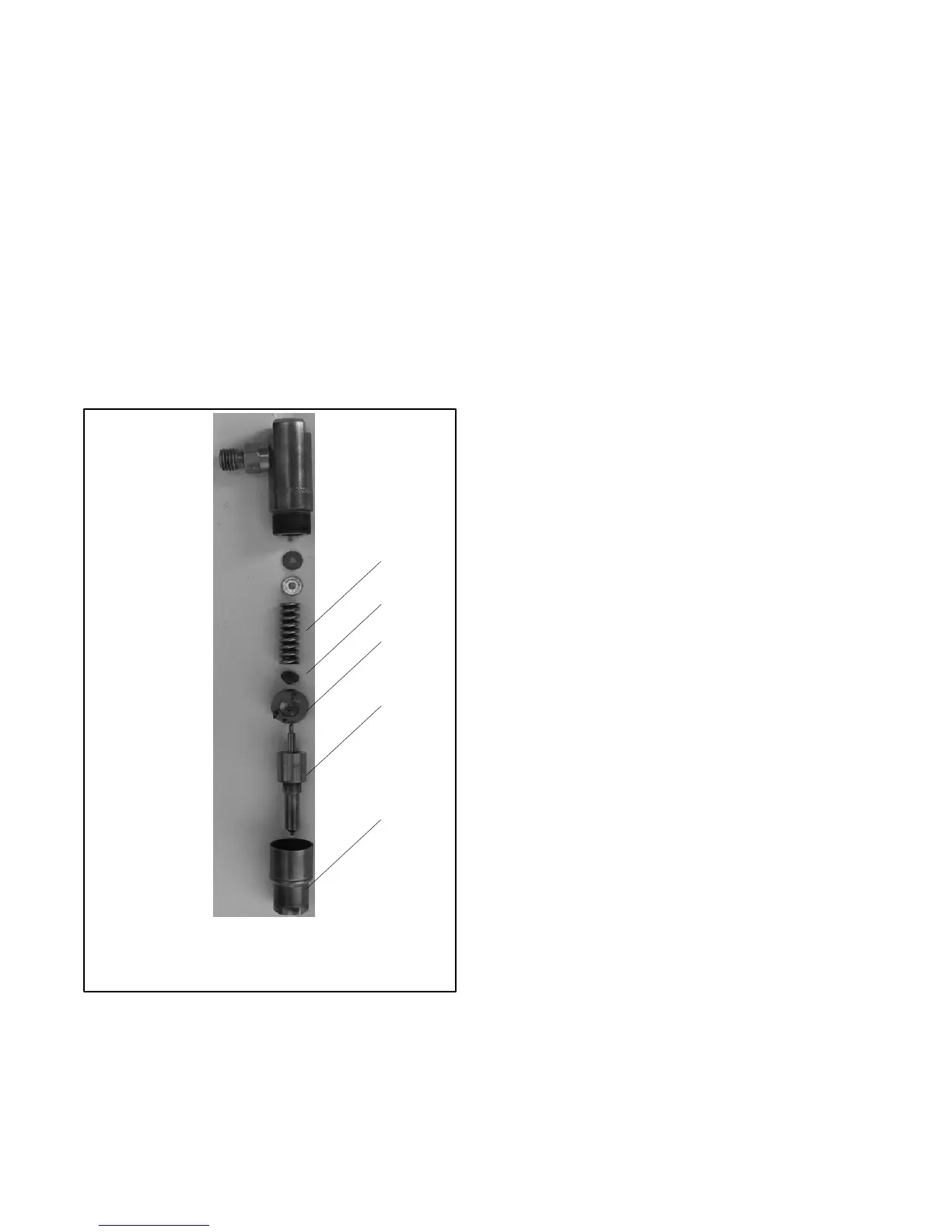

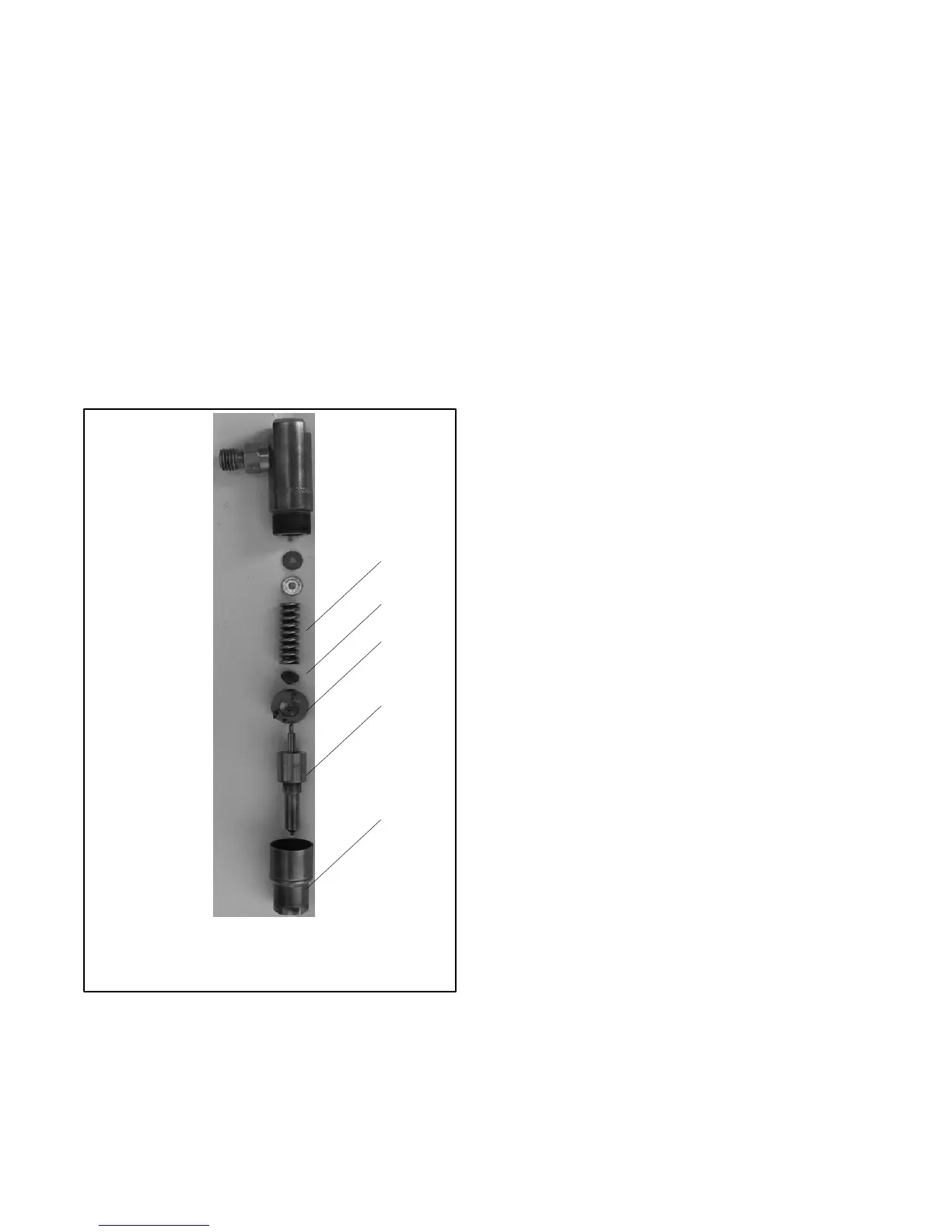

Injector Adjustment

1. If, during the injector pressure test, the pressure

values are not correct, replace the shims in the

injector.

a. Unscrew the injector nut.

b. Remove the nozzle assembly, pressure piece,

spring seat’s conical stop, spring, and shims.

SeeFigure5-7.

Note: A change of 0.1 mm (.004 in.) shim size can

modify the pressure value of the injector of

10 bar (145 psi). The thicker shim increases

the pressure value of the injector while the

thinner shim decreases the pressure value

of the injector. Add or remove shims to

obtain the correct pressure value.

1. Injector nut

2. Nozzle assembly

3. Pressure piece

4. Spring seat’s conical stop

5. Spring

1

2

3

5

4

Figure 5-7 Injector Components

Injector Overhaul

1. Inspect the injector assembly to ensure that the

nozzle’s needle is in the hole of the pressure piece.

2. If the nozzle leaks or does not atomize, replace the

entire nozzle.

3. Lapping of the nozzle needle is not recommended.

Loading...

Loading...