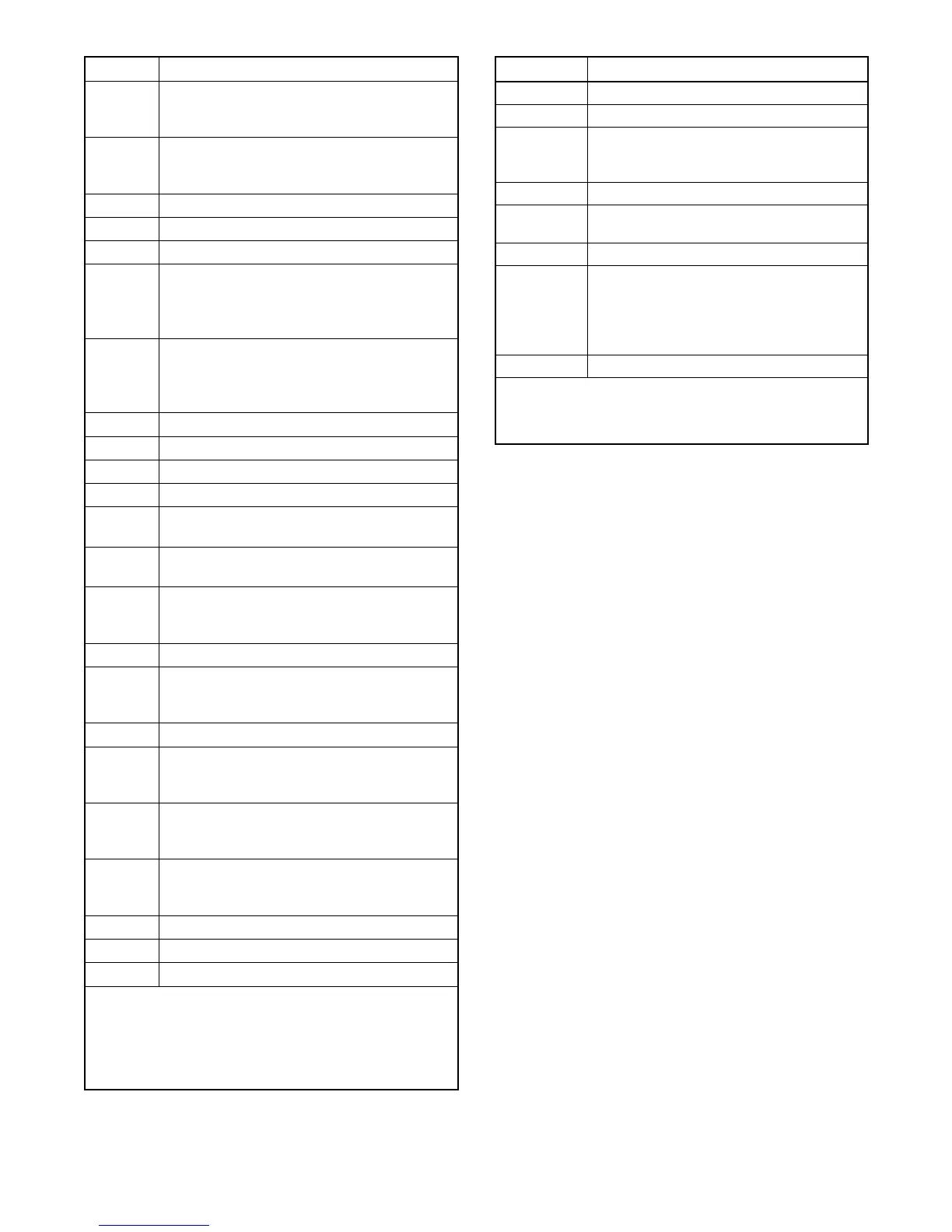

TP-6109 6/03 51Section 5 Wiring Diagrams

Terminal Purpose

1 Ground—emergency stop relay (K4)—connect

emergency stop across terminals TB1-1 and

1A *

1A Emergency stop relay (K4) coil; negative

side—connect emergency stop across

terminals TB1-1 and 1A *

2 Ground terminal

12

Overcrank (OC) indicator [

26

Auxiliary (AUX) indicator [

32 Common fault/prealarm line 1—A/V alarm or

common fault relay activated by OC, 12; AUX,

26; LWT, 35; HET, 36; LOP, 38; OS, 39; PHET,

40; PLOP, 41; and LF, 63 faults

32A Common fault/prealarm line 2—A/V alarm or

common fault relay activated by AUX, 26;

HET, 36; LOP, 38; OS, 39; and E-Stop, 48

faults

35 Low water temperature (LWT) indicator

36

High engine temperature (HET) indicator [

38

Low oil pressure (LOP) indicator [

39

Overspeed (OS) indicator [

40 Prealarm high engine temperature (PHET)

indicator [

41 Prealarm low oil pressure (PLOP)

indicator [

42A Battery voltage (fuse #1 protected)—

accessory power supply; customer may also

provide separate accessory power source

48

Emergency stop (ES) indicator [

56 Air damper (AD) indicator, if equipped;

standard on all 200--2000 kW Detroit

Diesel-powered models

60

System ready indicator [

61 Battery charger fault—connect battery charger

alarm contact to TB1-61 to activate fault lamp

(active low) (if used)

62 Low battery volts—connect battery charger

alarm contact to TB1-62 to activate fault lamp

(active low) (if used)

63 Low fuel (LF) fault—connect fuel level sensor

to TB1-63 to activate fault lamp (active low) (if

used)

70C Generator in cool down mode signal

70R Generator in running mode signal

80

Not in auto indicator [

* Connect jumper across terminals 1 and 1A if emergency stop

switch is not used.

[ Use a remote annunciator and/or A/V alarm kit as an indicator

with a d ry contact kit connected to controller terminal strip TB1.

Note: Not all terminals are used for all generator sets (see

appropriate wiring diagrams for specific generator set model).

Figure 5-20 Controller TB1 Terminal Strip

(Decision-Makert 3+ Controller)

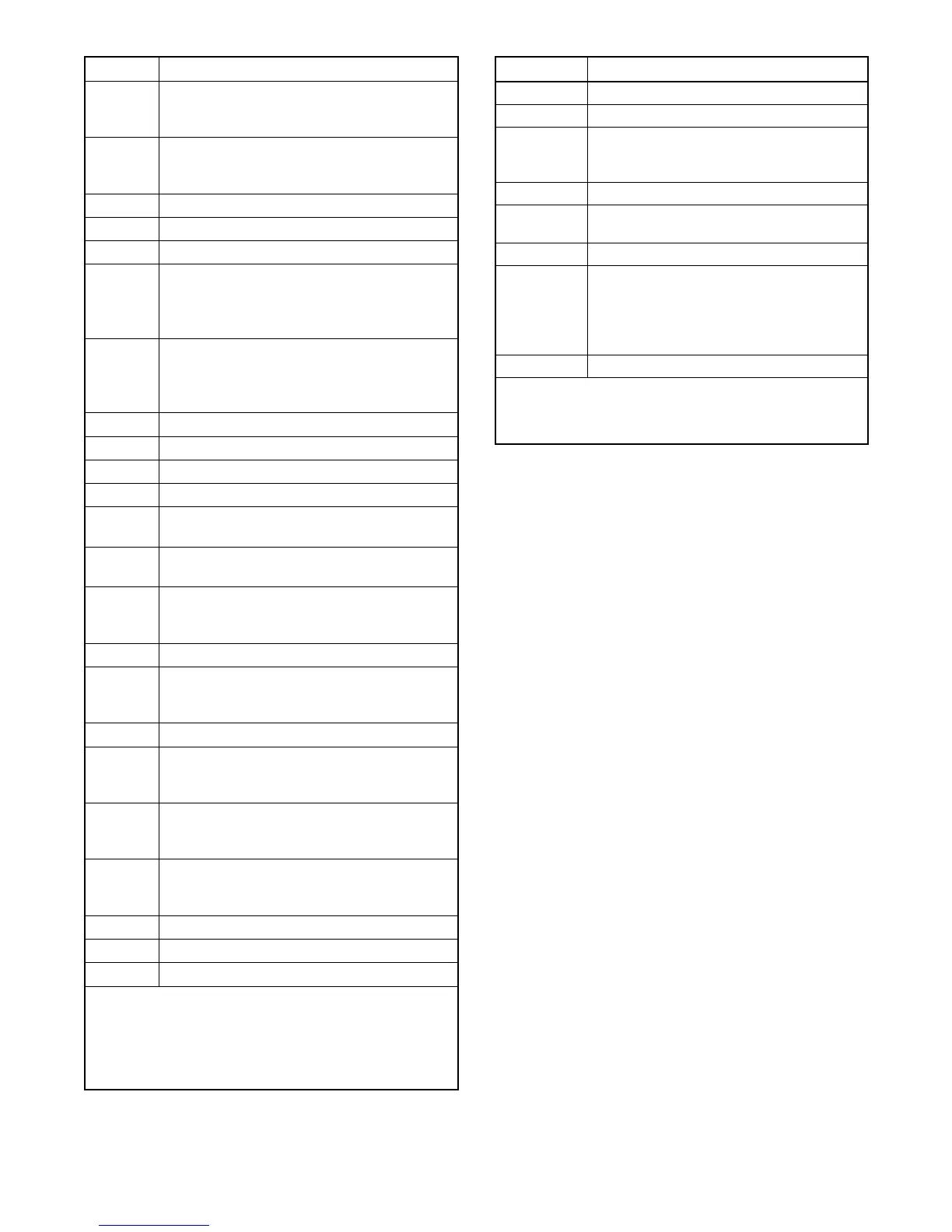

Terminal Purpose

1P Prime power operation

2P Prime power operation

3

Remote start ground—connect transfer

switchorremotestartswitchtoTB2--3and

TB2--4

3P Prime power operation

4

Remote start—connect transfer switch or

remote start switch to TB2--3 and TB2--4

4P Prime power operation

9

Crank mode selection (open: cyclic crank,

ground: continuous crank); connect TB2--9

to TB2--9A for continuous cranking; leave

TB2--9 open cyclic cranking; see starting

instructions in Section 2, Operation.

9A Crank mode ground

Note: To use prime power mode—place jumpers across TB2-1P to

TB2-2P, TB2-3P to TB2-4P, and TB2-3 to TB2-4. To deactivate

prime power mode—remove jumpers across TB2-1P to TB2-2P,

TB2-3P to TB2-4P, and TB2-3 to TB2-4.

Figure 5-21 Controller TB2 Terminal Strip

(Decision-Makert 3+ Controller)

Loading...

Loading...