TP-6391 9/08 55Section 5 Component Testing and Adjustment

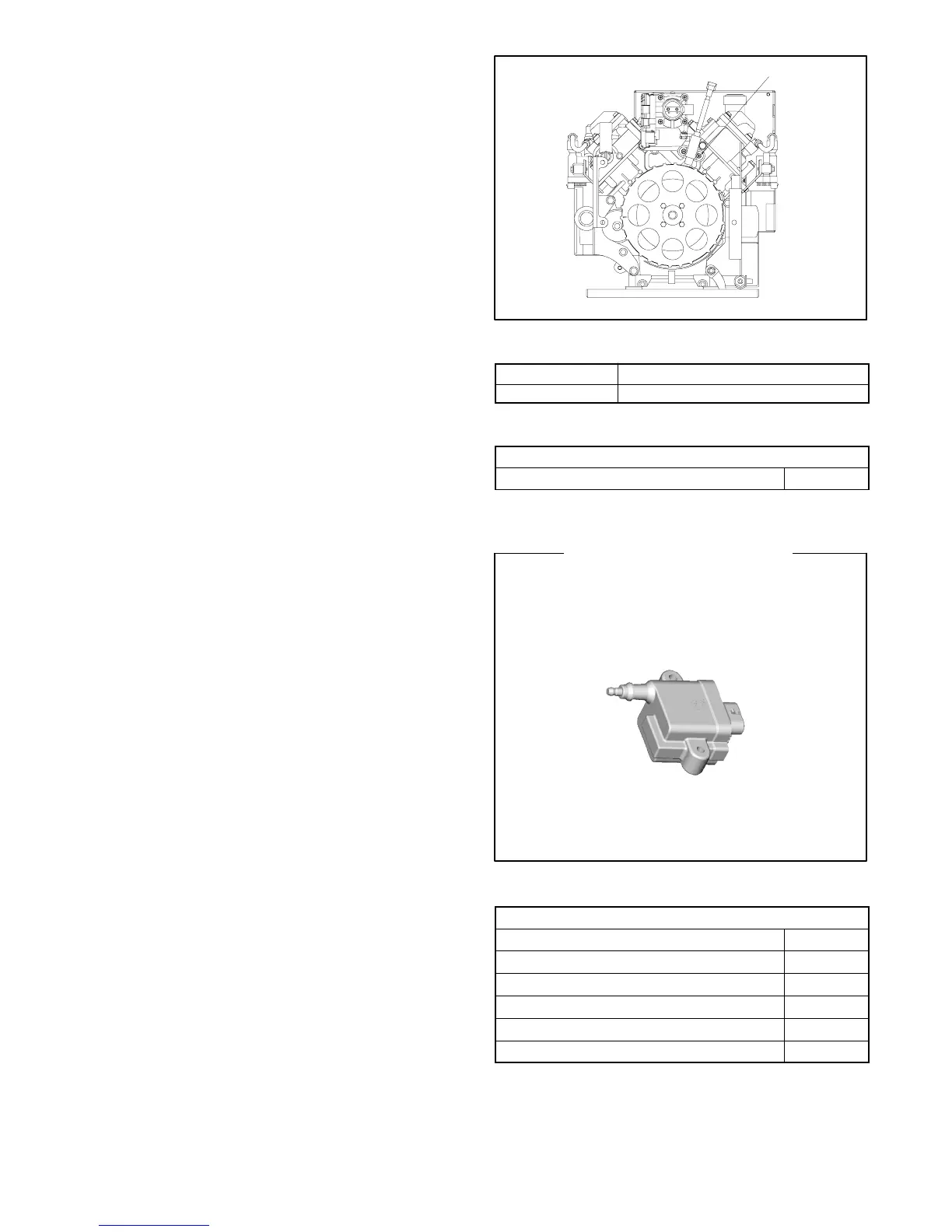

Crankshaft Position Sensor

The crankshaft position sensor monitors speed control,

timing (firing of spark plugs), and fuel injection. See

Figure 5-16 for the crankshaft position sensor location.

The crankshaft position sensor is an electromagnetic

device which contains a permanent magnet surrounded

by a winding. The sensor is used with the timing wheel.

The timing wheel has 30 gear teeth with 5 teeth removed

at precise locations allowing the ECM a very accurate

speed reference signal. The timing wheel rotation near

the sensor’s tip changes the magnetic flux, creating an

analog voltage signal in the sensor coil.

The spark is sent to the appropriate cylinder via the rotor

arm and spark plug wires. The ECM uses the signal

from the crankshaft position sensor to determine the

engine position and RPM. This information, together

with the TPS and TMAP sensor information is used to

calculate the correct ignition timing settings.

To test the crankshaft position sensor, set the generator

set master switch to the OFF position and allow the

generator set to cool. Disconnect the crankshaft

position sensor and use an ohmmeter to measure the

resistance across the sensor pins. See Figure 5-18.

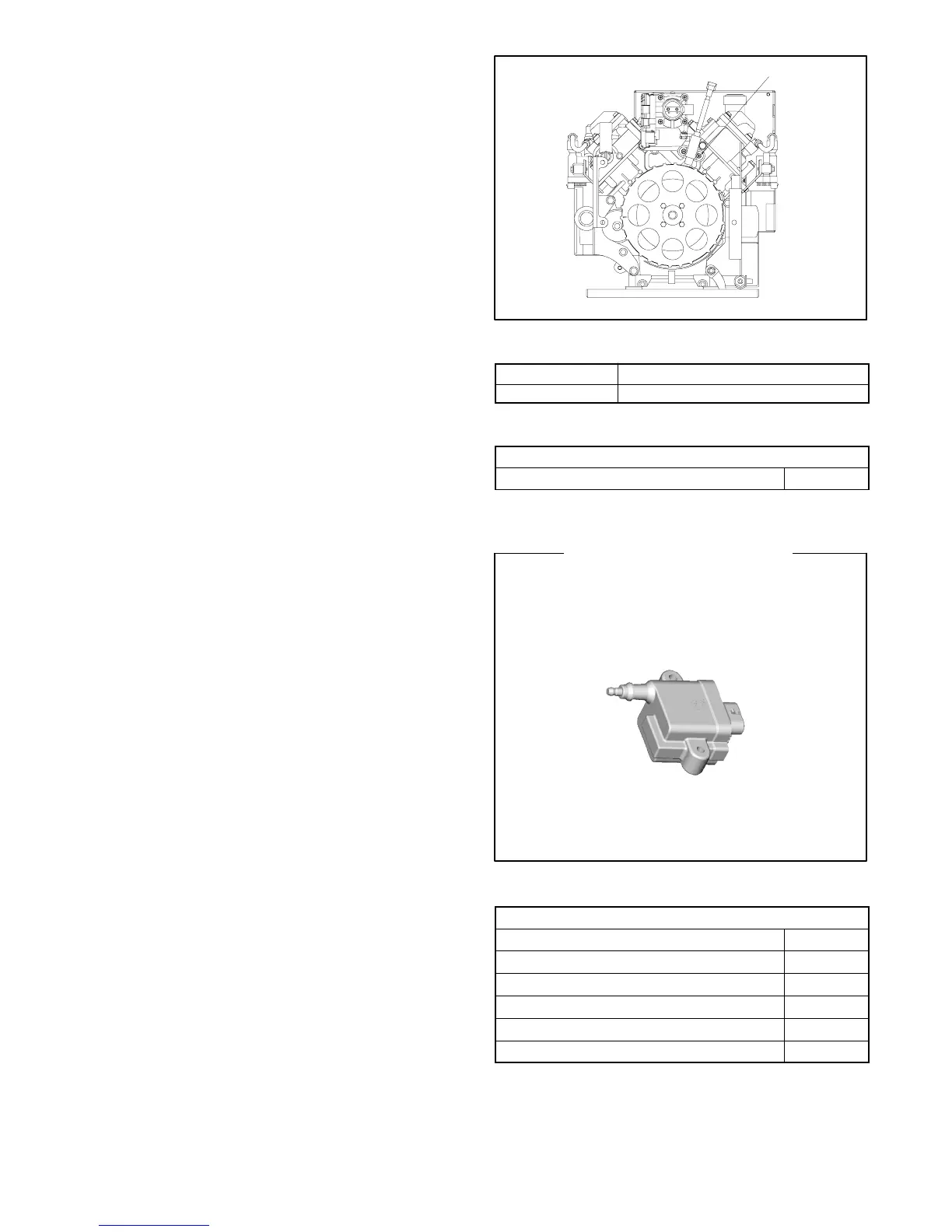

Ignition Coil

This system uses a single coil incorporating the ignition

driver circuitry inside the coil. See Figure 5-19. The

ECM signals the coil to begin its cycle. Then the coil

waits for the trigger signal from the ECM.

To test the ignition coil, set the generator set master

switch to the OFF position and allow the generator set to

cool. Disconnect the ignition coil and use an ohmmeter

to measure the resistance across the coil pins. See

Figure 5-20 for the coil resistance.

1

GM39685B-J

1. Crankshaft position sensor

Figure 5-16 Crankshaft Position Sensor Location

Model Crankshaft Position Sensor Gap

All 0.030--0.060 in.

Figure 5-17 Crankshaft Position Sensor Gap

Crankshaft Position Sensor Pin Resistance (approx.)

Pin 1 (+) to Pin 2 (--) 320 Ohms

Figure 5-18 Crankshaft Position Sensor Resistance

Check

Figure 5-19 Ignition Coil

Ignition Coil Pin Resistance Check (approx.)

Pin A (SIGNAL) to Pin B 10 kOhms

Pin A (SIGNAL) to Pin D 34 kOhms

Pin A (SIGNAL) to Pin E (PWR) 15 kOhms

Pin B to Pin D 44 kOhms

Pin B to Pin E (PWR) 26 kOhms

Pin D to Pin E (PWR) 17 kOhms

Figure 5-20 Ignition Coil Resistance Check

Loading...

Loading...