eChoke

™

System Standard Checks

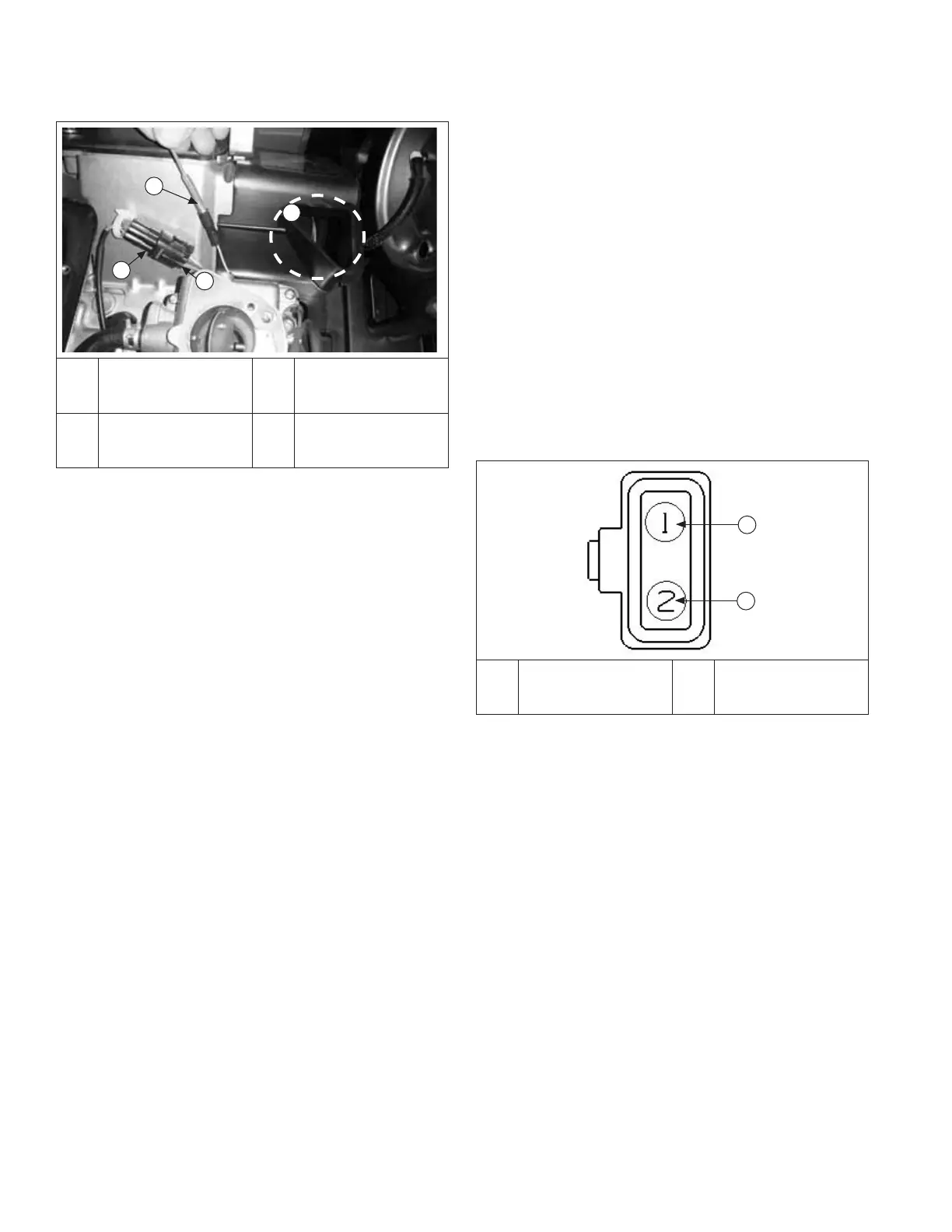

A

C

B

D

A

Rotary Stepper

Motor 4 Pin

Connector

B Main Wiring Harness

C MIL Test Connector D

2 Pin Connector

Access (Some

Engines)

NOTE: Remove air cleaner system to access carburetor

and eChoke

™

components. Refer to

Disassembly/Inspection and Service and

Reassembly procedure.

Use these procedures and guides to troubleshoot this

system and its components. Perform a system reset

prior to troubleshooting to verify problem still exists. Start

with key switch in OFF position, operate through On-Off -

On sequence and restart engine.

There are standard checks that should be made initially

to help isolate possible problems:

1. Check choke assembly to ensure choke is properly

connected. (Link connected to carburetor and

stepper motor lever.) Removal of air cleaner cover,

element/precleaner, and air cleaner base is required.

2. Make sure link is located and connected properly.

3. Check that choke stepper motor is functioning.

(Operate key switch through On-Off -On sequence to

inspect for any choke movement.) Rotary stepper

motor function can be tested and confi rmed using a

stepper motor controller tool and jumper lead tool.

Refer to Tools and Aids. Testing instructions are

included with these tools.

4. Check that constant power line (RED/GREEN stripe)

connection is connected directly to starter stud.

5. Check for battery voltage (nonoperating), must be

greater than 12.2 VDC open circuit.

(Low battery voltage may prevent proper operation

of stepper motor.)

6. eChoke

™

system is equipped with an MIL connector

that will allow connection of an LED lamp to show

normal eChoke

™

operation or specifi c error codes.

MIL connector is accessible by removing air cleaner

system. This lead (white/red stripe) with a bullet

connector next to stepper motor 4 pin connector

(refer to A and C shown above) to which an LED

(connected to lead and +12 volt power line) can be

connected to review operation or look for error

codes. Once a lamp is connected, operator can

attempt to run through a normal start/crank/run/off

sequence and monitor blink codes to determine if

controller operation is correct.

Both normal operation and error code indication is

listed in blink code table that follows (on next page).

Note that code changes for each level of operation.

7. With air cleaner system removed, connect an LED

test lamp (see Blink Codes for more detail) or use

stepper motor controller tool (see Tools and Aids)

MIL bullet terminal and attach tool battery jump leads

to battery. Refer to instructions in Blink Codes,

Operational Tests, and Failure Modes (on this page

and next page).

8. If no MIL light activity is seen, using a DVOM, attach

black meter lead to battery ground, connect red

meter lead to starter stud, battery voltage should be

seen (must be above 12.2 VDC as in step 3).

9. Locate and carefully slide 2 pin connector through

blower housing air duct and unplug (some engines).

If 2 pin connector is not visible through this duct,

blower housing must be removed to gain access.

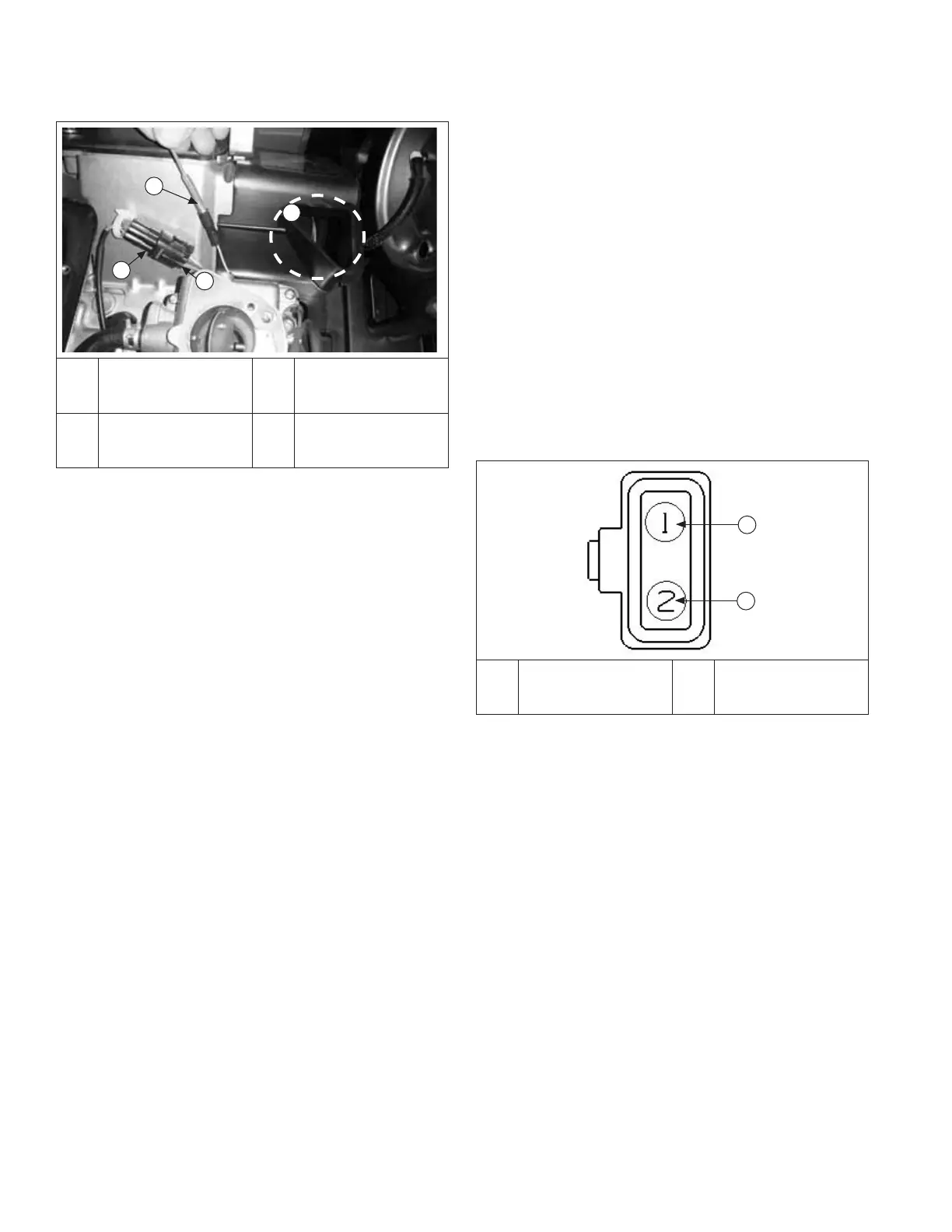

A

B

A

12 Volt Switched

Power Red Wire

B

12 Volt Constant

Power Red/Green

Wire

With key OFF, using red meter lead, probe terminal

2 (red/green wire). Constant power battery voltage

should be seen. If no voltage is seen, cycle key

switch ON and OFF and repeat test. If no voltage is

seen, confi rm harness ground connection. If still no

power, possible fusible link failure has occurred in

harness. Go to step 11 and test for fuse continuity.

10. If voltage is seen in step 9, move red meter lead to

terminal 1. Key OFF, no voltage should be seen.

With meter lead connected to terminal 1, turn key to

ON position. Battery voltage should now be seen.

11. If no power seen in steps 9 and 10, check for

continuity through constant power line (possible

fusible link failure). Disconnect battery; remove red/

green wire eyelet terminal from starter solenoid stud.

Using a DVOM, check for continuity between eyelet

terminal and terminal 2 of 2 pin connector. If no

continuity is found, wiring harness must be replaced.

Fuel System

36 24 690 06 Rev. PKohlerEngines.com

Loading...

Loading...