Troubleshooting eChoke

™

Related Causes

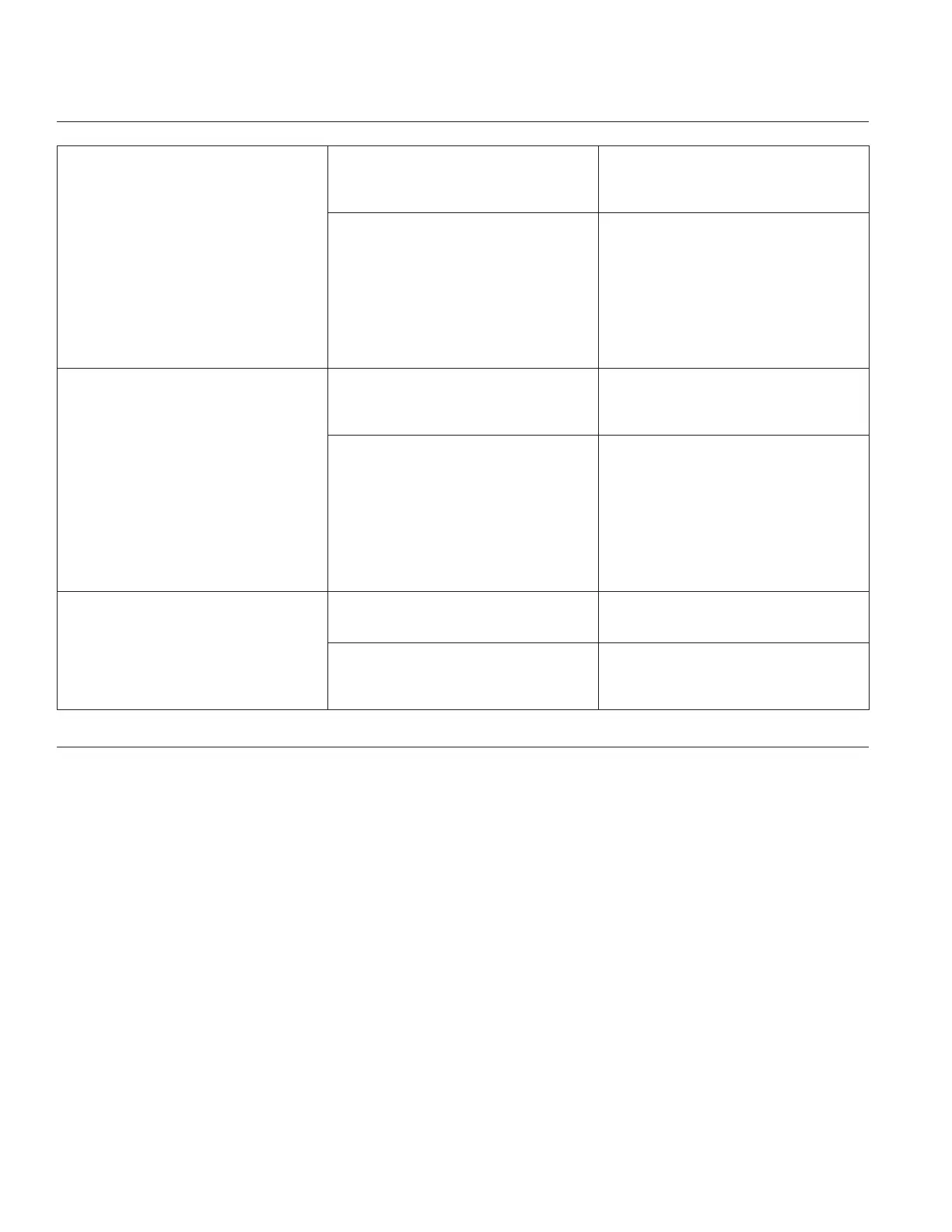

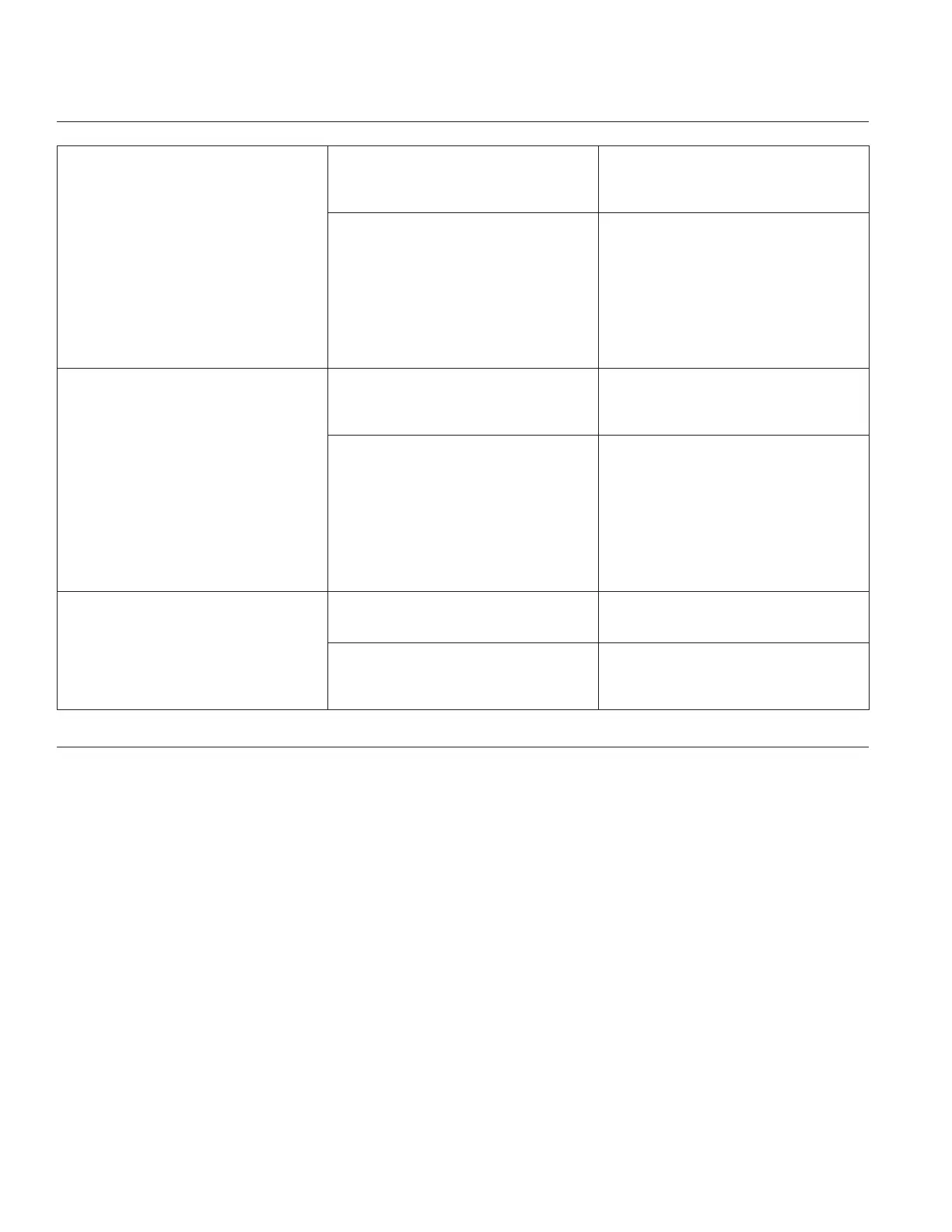

Condition Possible Cause Conclusion

Engine starts hard, runs rough, or

stalls at idle speed.

Choke not closing/moving

a. Broken or missing link.

Stepper motor/bracket/link assembly

must allow for full travel, make sure

link is located properly and

connected.

b. Loss of constant power or

switched power.

c. Loss of system ground.

d. Fusible link is open.

e. Stepper motor not functioning.

f. Electronic component in

Master ignition/control module

is not functioning.

Bad wire harness connection, fusible

link failure.

Component failure in Master

controller/ignition.

Bad Master Controller harness.

Engine runs rich (indicated by black,

sooty exhaust smoke, misfi ring, loss

of speed and power, governor

hunting, or excessive throttle

opening).

Choke partially closed during

operation.

a. Broken or missing link.

Stepper motor/bracket/link assembly

must allow for full travel, make sure

link is located properly and

connected.

b. Loss of constant power or

switched power.

c. Loss of system ground.

d. Fusible link is open.

e. Stepper motor not functioning.

f. Electronic component in

Master ignition/control module

is not functioning.

Bad wire harness connection, fusible

link failure.

Component failure in Master

controller/ignition.

Bad Master Controller harness.

Engine runs lean (indicated by

misfi ring, loss of speed and power,

governor hunting, or excessive

throttle opening).

Key integrated component in Master

ignition/control module is not

functioning.

Bad ignition module on specifi c

cylinder.

Incorrect set up of stepper motor/link/

bracket to carburetor.

Stepper motor/bracket/link assembly

must allow for full travel, make sure

link is located properly and

connected.

Starting an Engine Equipped with eChoke

™

1. This eChoke

™

system automatically controls choke plate position for starting.

2. Activate starter switch. Release switch as soon as engine starts.

3. If engine does not start, remove air cleaner system from carburetor.

4. Confi rm connection of stepper motor assembly to carburetor.

5. With key switch set to OFF, choke plate should be fully closed.

6. Confi rm movement of choke plate:

a. Shut off key switch and test for full travel of rotary stepper motor by disconnection and reconnection of

negative (ground) contact at battery.

b. If there is still no movement, separate tests to validate battery voltage and power and ground connection to

master controller need to be performed.

7. If movement is noted, attempt to crank and start engine. (Do not exceed 10 seconds of cranking.)

Fuel System

38 24 690 06 Rev. PKohlerEngines.com

Loading...

Loading...