4524 690 01 Rev. S KohlerEngines.com

EFI SYSTEM-ELECTRONIC THROTTLE BODY (ETB) ECH

3. Check to make sure intake manifold is not loose and

TMAP sensor is not loose. Loose parts would allow

a vacuum leak, making TMAP sensor report

misleading information to ECU.

a. Tighten all hardware and perform an ECU Reset

Procedure to see if MIL will display a fault with

sensor again. If MIL fi nds a fault with TMAP

sensor, replace it.

Oxygen Sensor (O2)

Identify style of sensor to ensure proper testing and

installation torque.

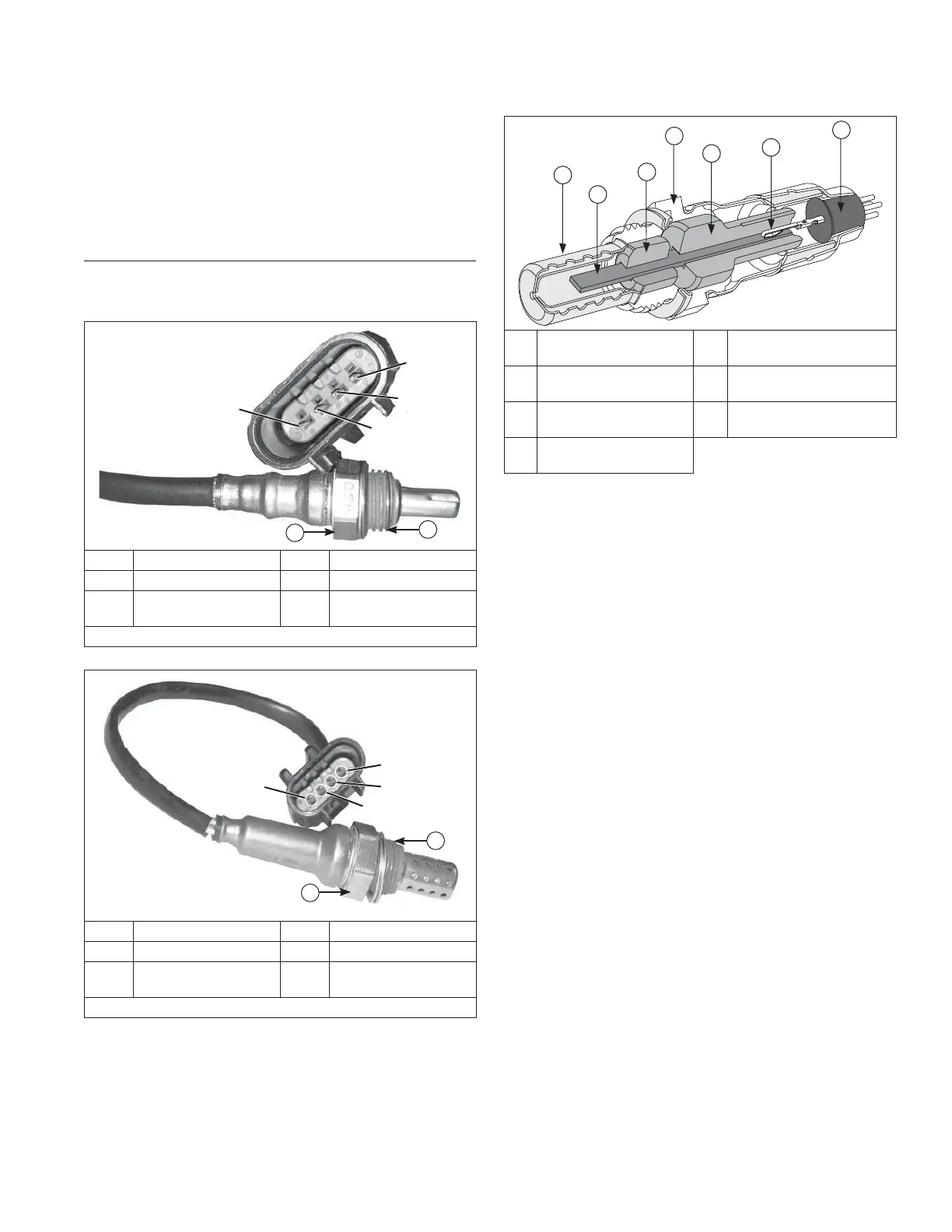

Style 1 (Smaller Sensor)

Pin D

Pin C

Pin B

Pin A

A

B

Pin A Heater + Pin B Heater -

Pin C Sensor Output Pin D Sensor Ground

A

14 mm or 9/16 in.

Wrench Size

B

12 mm x 1.25

Thread Size

Installation Torque 18 N·m (159 in. lb.)

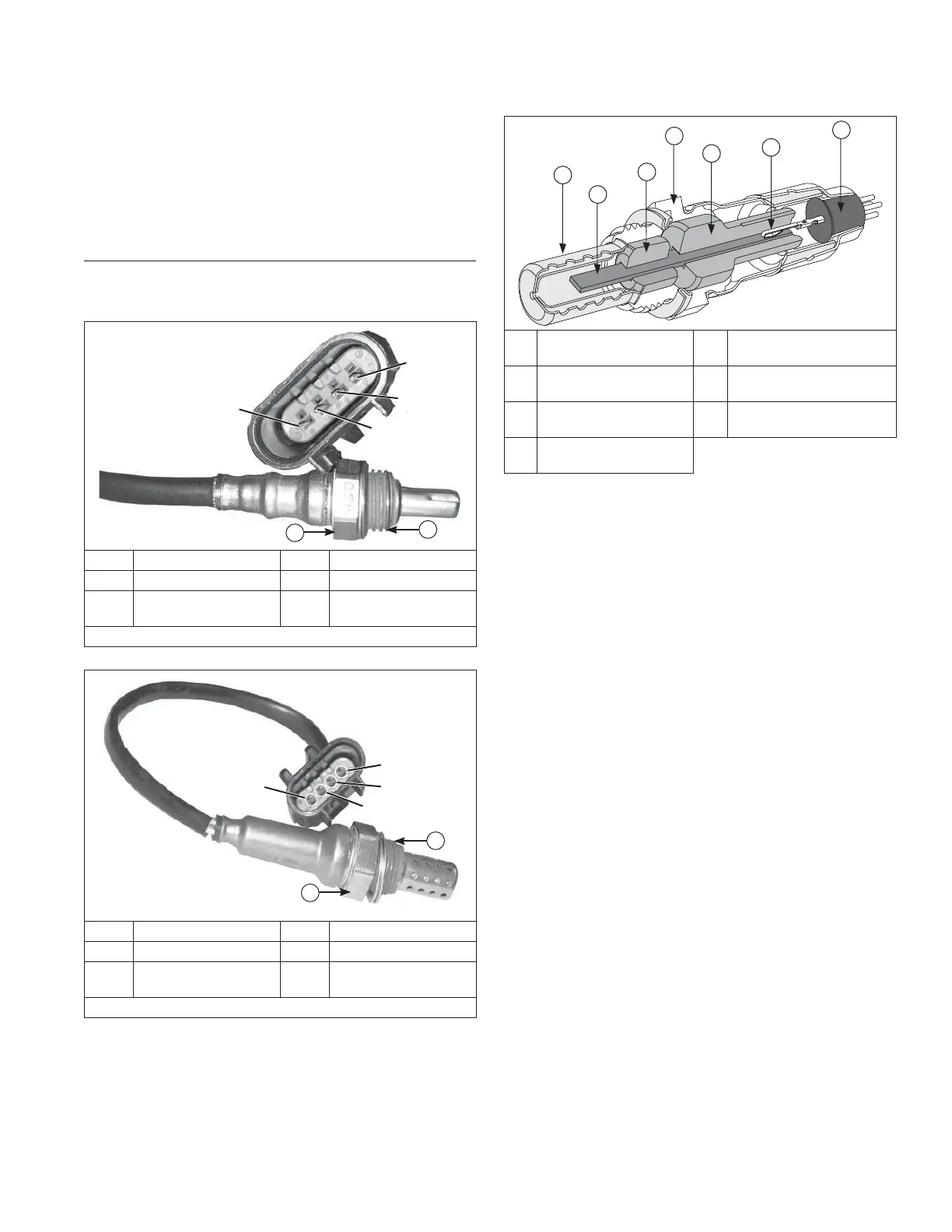

Style 2 (Larger Sensor)

Pin D

Pin C

Pin B

Pin A

A

B

Pin A Heater + Pin B Heater -

Pin C Sensor Output Pin D Sensor Ground

A

22 mm or 7/8 in.

Wrench Size

B

18 mm x 1.5

Thread Size

Installation Torque 50.1 N·m (37 ft. lb.)

Cutaway Oxygen Sensor Components (O2)

A

B

C

D

E

F

G

A Protection Shield B

Planar Element

and Heater

C Lower Insulator D

Stainless Steel

Housing

E Upper Insulator F

Terminal Connection

to Element

G

High Temp

Water Seal

Temperature must be controlled very accurately and gas

constituents measured to a high degree of accuracy for

absolute sensor measurements. This requires laboratory

equipment to determine a good or bad sensor in fi eld.

Furthermore, as with most devices, intermittent problems

are diffi cult to diagnose. Still, with a good understanding

of system and sensor, it is possible to diagnose many

sensor problems in fi eld.

Using KOHLER

®

Diagnostic System (KDS) Gen 2, see

Tools and Aids, connected to ECU is a useful technique

for observing sensor performance. However, user must

understand that such software reads a signal generated

by ECU. If there is an ECU or wiring problem, readings

could be misinterpreted as a sensor problem. Digital

nature of signal to KDS tool means that it is not reading

continuous output of sensor. A voltmeter can also be

used as an eff ective tool in diagnosing sensors.

Using injector timing test within KDS tool will aid in

testing operation of O2 sensor. See instructions within

help (?) area of injector timing test.

It is advisable to use an electronic meter such as a

digital voltmeter. Simple mechanical meters may place

a heavy electrical load on sensor and cause inaccurate

readings. Since resistance of sensor is highest at

low temperatures, such meters will cause largest

inaccuracies when sensor is in a cool exhaust.

Loading...

Loading...