40

Disassembly/Inspection and Service

KohlerEngines.com 18 690 01 Rev. B

Remove Camshaft and Valve Tappets

1. Remove camshaft by pulling it straight out of

crankcase.

2. Remove valve tappets by pulling straight out of

crankcase. Mark their positions.

Inspection and Service

Inspect gear teeth of camshaft. If teeth are badly worn

or chipped, or if some are missing, replacement of

camshaft will be necessary. If unusual wear or damage

is evident on either camshaft lobes or mating tappets

camshaft and both tappets must be replaced. Check

condition and operation of Automatic Compression

Release (ACR) mechanism.

Automatic Compression Release (ACR)

ACR Operation Details

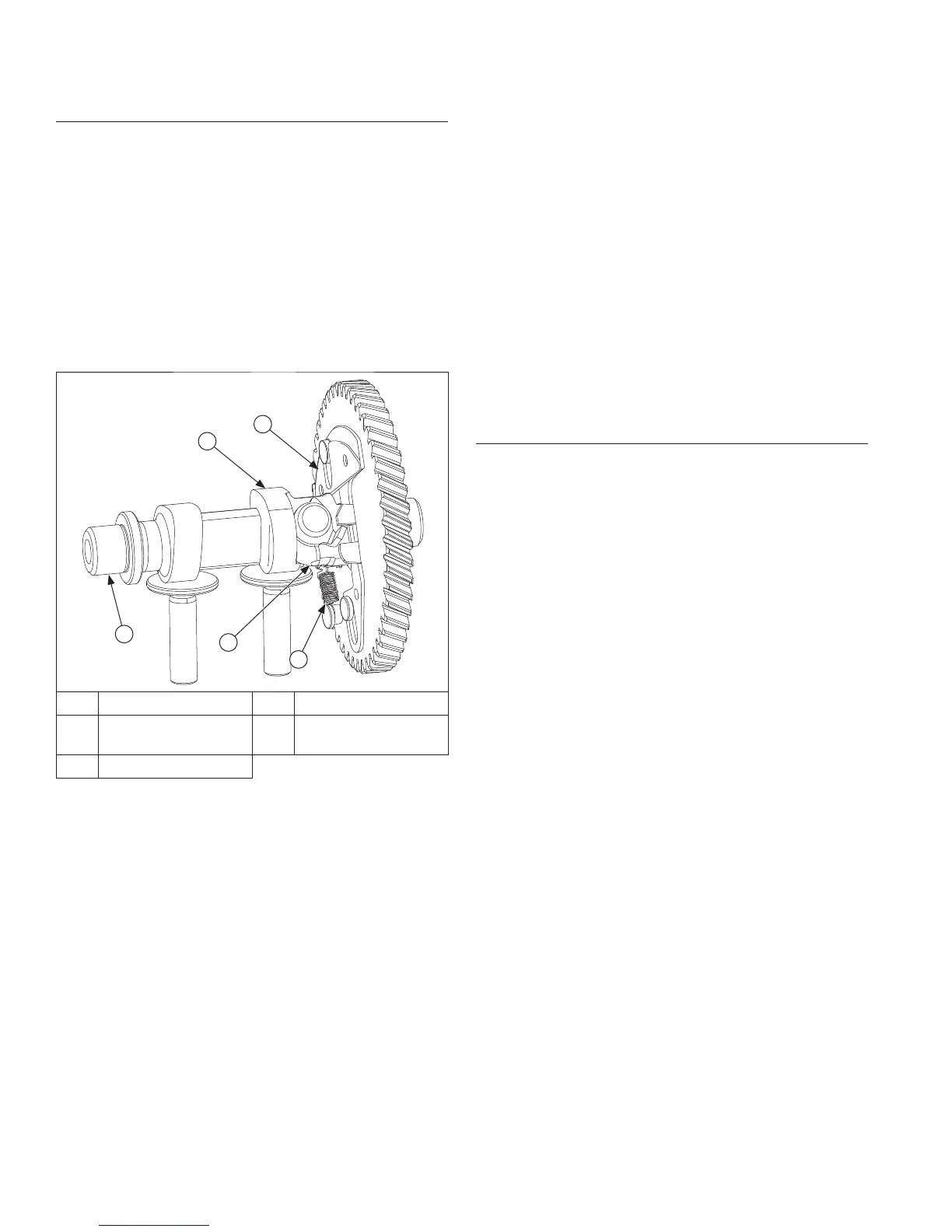

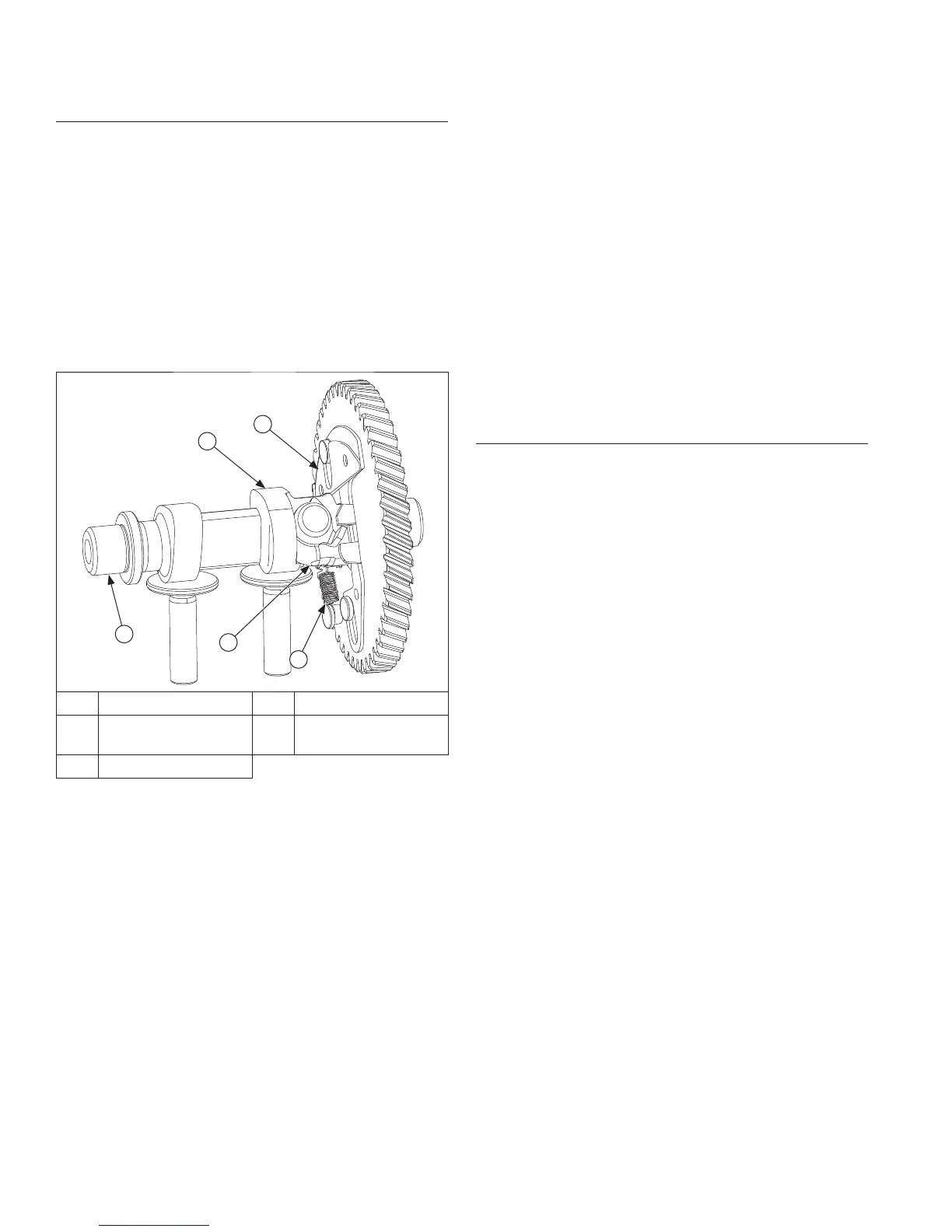

B

C

E

D

A

A Camshaft B Exhaust Cam Lobe

C

Decompression

Weight

D Return Spring

E Arm

These engines are equipped with an ACR mechanism.

ACR lowers compression at cranking speeds to make

starting easier.

Operation

ACR mechanism consists of a decompression weight

and arm mounted to camshaft, and activated by a return

spring. When engine is rotating at low cranking speeds

(1000 RPM or less), decompression weight holds arm

so it protrudes above heel of exhaust lobe. This holds

exhaust valve off its seat during fi rst part of compression

stroke.

After engine speed increases above approximately 1000

RPM, centrifugal force causes decompression weight

to move outward, causing arm to retract. When in this

position, arm has no effect on exhaust valve and engine

operates at FULL compression and power.

Benefi ts

As a result of reduced compression at cranking speeds,

several important benefi ts are obtained:

1. Manual (retractable) starting is much easier. Without

ACR, manual starting would be virtually impossible.

2. Electric start models can use a smaller starter and

battery that are more practical for application.

3. ACR eliminates need for a spark retard/advance

mechanism. A spark retard/advance mechanism

would be required on engines without ACR to

prevent kickback that would occur during starting.

ACR eliminates this kickback, making manual

starting safer.

4. Choke control setting is less critical with ACR. If

fl ooding occurs, excess fuel is blown out opened

exhaust valve and does not hamper starting.

5. Engines with ACR start much faster in cold weather

than engines without ACR.

6. Engines with ACR can be started with spark plugs

that are worn or fouled. Engines without ACR are

more diffi cult to start with those same spark plugs.

Remove Piston, Connecting Rod, and Crankshaft

NOTE: If a carbon ridge is present at top of cylinder

bore, use a ridge reamer to remove it before

attempting to remove piston.

1. Remove screws securing end cap to connecting rod.

Remove end cap. While guiding connecting rod,

slide piston and connecting rod from cylinder bore.

2. Remove crankshaft from crankcase.

Connecting Rod Inspection and Service

Check bearing area (big end) for excessive wear, score

marks, running and side clearances. Replace connecting

rod and end cap if scored or excessively worn.

Service replacement connecting rods are available in

STD size.

Pistons and Rings Inspection

Scuffi ng and scoring of pistons and cylinder walls occurs

when internal engine temperatures approach welding

point of piston. Temperatures high enough to do this are

created by friction, which is usually attributed to improper

lubrication and/or overheating of engine.

Normally, very little wear takes place in piston boss or

piston pin area. If original piston and connecting rod can

be reused after new rings are installed, original pin can

also be reused but new piston pin retainers are required.

Piston pin is included as part of piston assembly; if pin

boss in piston or pin itself is worn or damaged, a new

piston assembly is required.

Ring failure is usually indicated by excessive oil

consumption and blue exhaust smoke. When rings fail,

oil is allowed to enter combustion chamber where it is

burned along with fuel. High oil consumption can also

occur when piston ring end gap is incorrect, because

ring cannot properly conform to cylinder wall under this

condition. Oil control is also lost when ring gaps are not

staggered during installation.

When cylinder temperatures get too high, lacquer and

varnish collect on pistons, causing rings to stick, which

results in rapid wear. A worn ring usually takes on a

shiny or bright appearance.

Scratches on rings and pistons are caused by abrasive

material such as carbon, dirt, or pieces of hard metal.

Loading...

Loading...