78

Reassembly

KohlerEngines.com 32 690 01 Rev. G

Install Intake Manifold

Torque Sequence

1

2

3

4

NOTE: If wires were disconnected from ignition modules

on engines with DSAM, reattach leads and seal

base of terminal connectors with GE/Novaguard

G661 or equivalent dielectric compound. Beads

should overlap between terminals to form a solid

bridge of compound. Do not put any compound

inside terminals.

1. Install intake manifold using new O-rings, with wiring

harness attached, onto cylinder heads. Slide any

wiring harness clips onto appropriate bolts before

installing. Ground lead for fuel solenoid (if equipped)

should be attached to inner screw on side 2. Using

sequence shown, torque screws in 2 increments,

fi rst to 7.4 N·m (66 in. lb.), then to 9.9 N·m

(88 in. lb.).

2. Connect kill lead to tab terminal on standard ignition

modules.

Install Rectifi er-Regulator (if equipped)

1. Install B+ terminal/lead into center position of

rectifi er-regulator plug so it locks in place, and

connect plug to rectifi er-regulator.

2. Attach rectifi er-regulator to opening in backing plate

from underside, and secure with mounting screws.

Torque screws to 4.0 N·m (35 in. lb.)

Install Inner and Outer Cylinder Baffl es

1. Attach outer cylinder baffl es and secure with M6

screw (lower cylinder location), and M5 screw into

backing plate. Tighten screws as listed following step

2.

2. Attach inner baffl es including any lifting straps to

cylinder head fl anges and to 2 crankcase mounting

bosses. Lift strap should be outside outer baffl e.

Secure with M5 screws. Remaining lower inner

baffl e mounting screws will be installed later.

Torque baffl e mounting screws:

M5 screws: 6.2 N·m (55 in. lb.) into a new cored

hole, or 4.0 N·m (35 in. lb.) into a used hole.

M6 screws: 10.7 N·m (95 in. lb.) into a new cored

hole, or 7.3 N·m (65 in. lb.) into a used hole.

3. Install spark advance module (DSAM) if equipped,

onto outer cylinder baffl e.

Install Carburetor

WARNING

Explosive Fuel can cause fi res and severe

burns.

Do not fi ll fuel tank while engine is hot or

running.

Gasoline is extremely fl ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or fl ames. Spilled fuel could ignite

if it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

1. Install a new carburetor gasket. Make sure all holes

align and are open.

2. Install carburetor, throttle linkage and governor lever

as an assembly.

3. If carburetor is equipped with a fuel solenoid,

connect red (power) lead. Attach eyelet terminal of

ground lead to inner top carburetor cover mounting

screw.

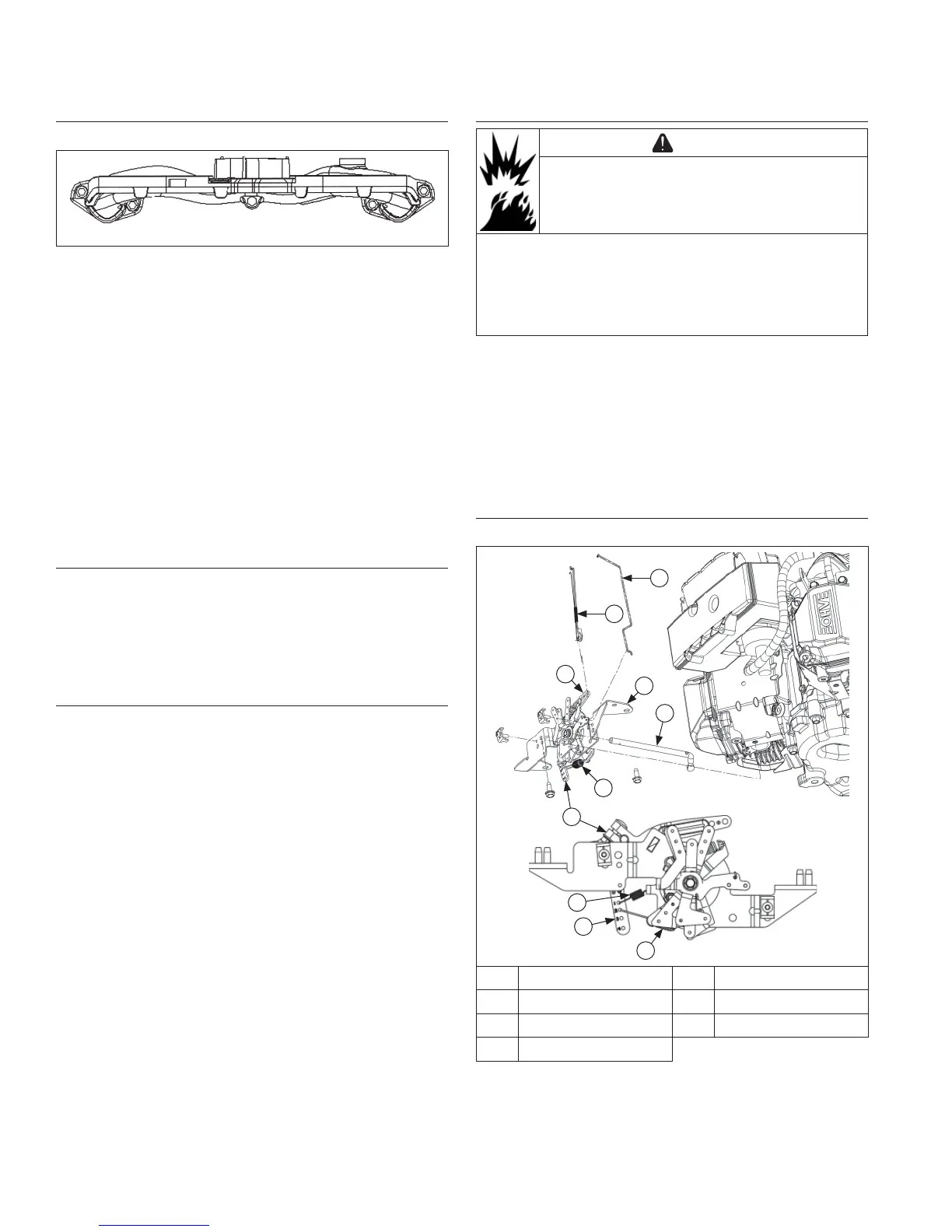

Install External Governor Controls

Control Bracket Components

F

G

C

C

C

B

A

D

D

E

A Choke Linkage B Throttle Linkage

C Governor Lever D Governor Spring

E Cross Shaft F Control Bracket

G Dampener Spring

Loading...

Loading...