103

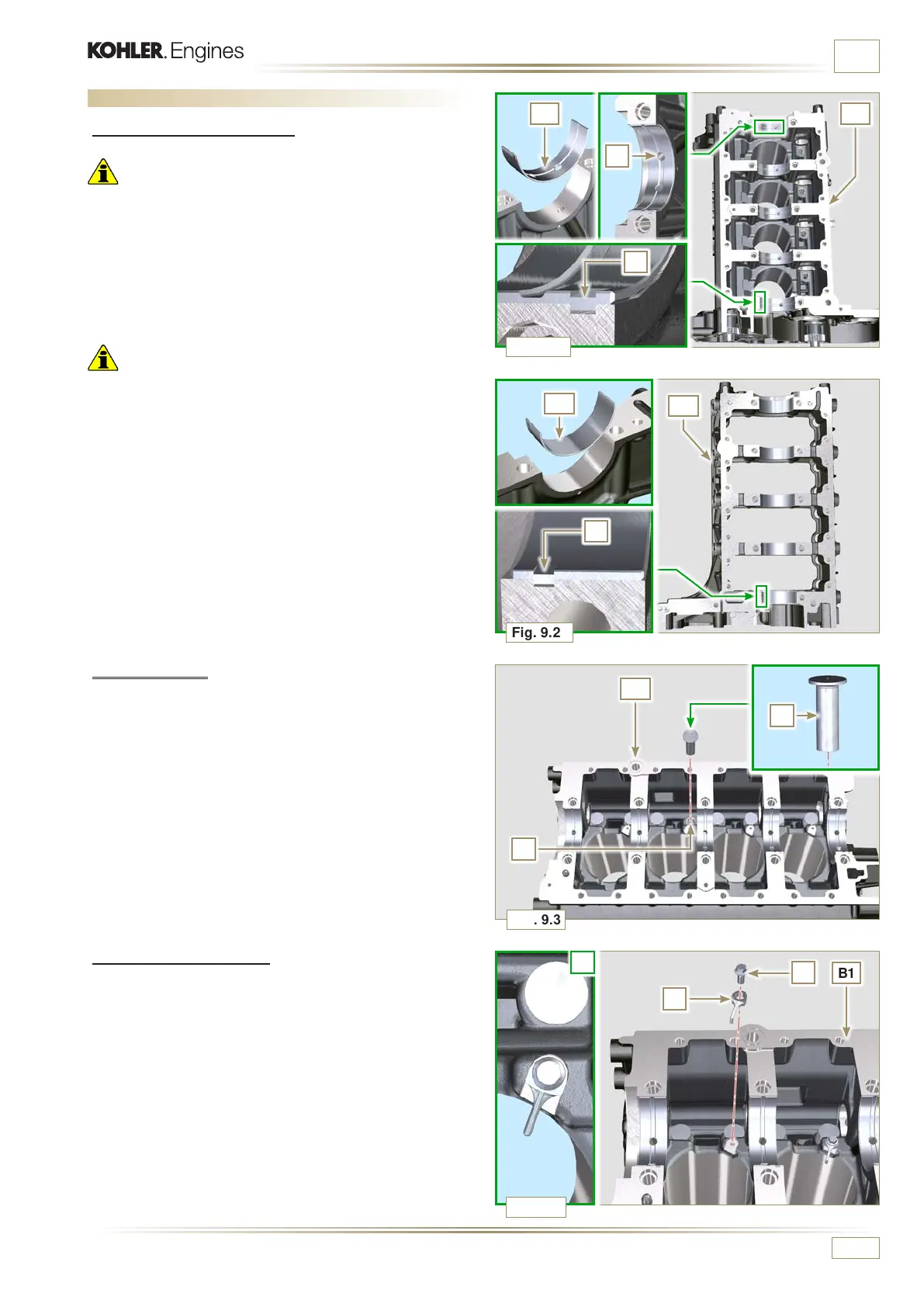

Fig. 9.2

C

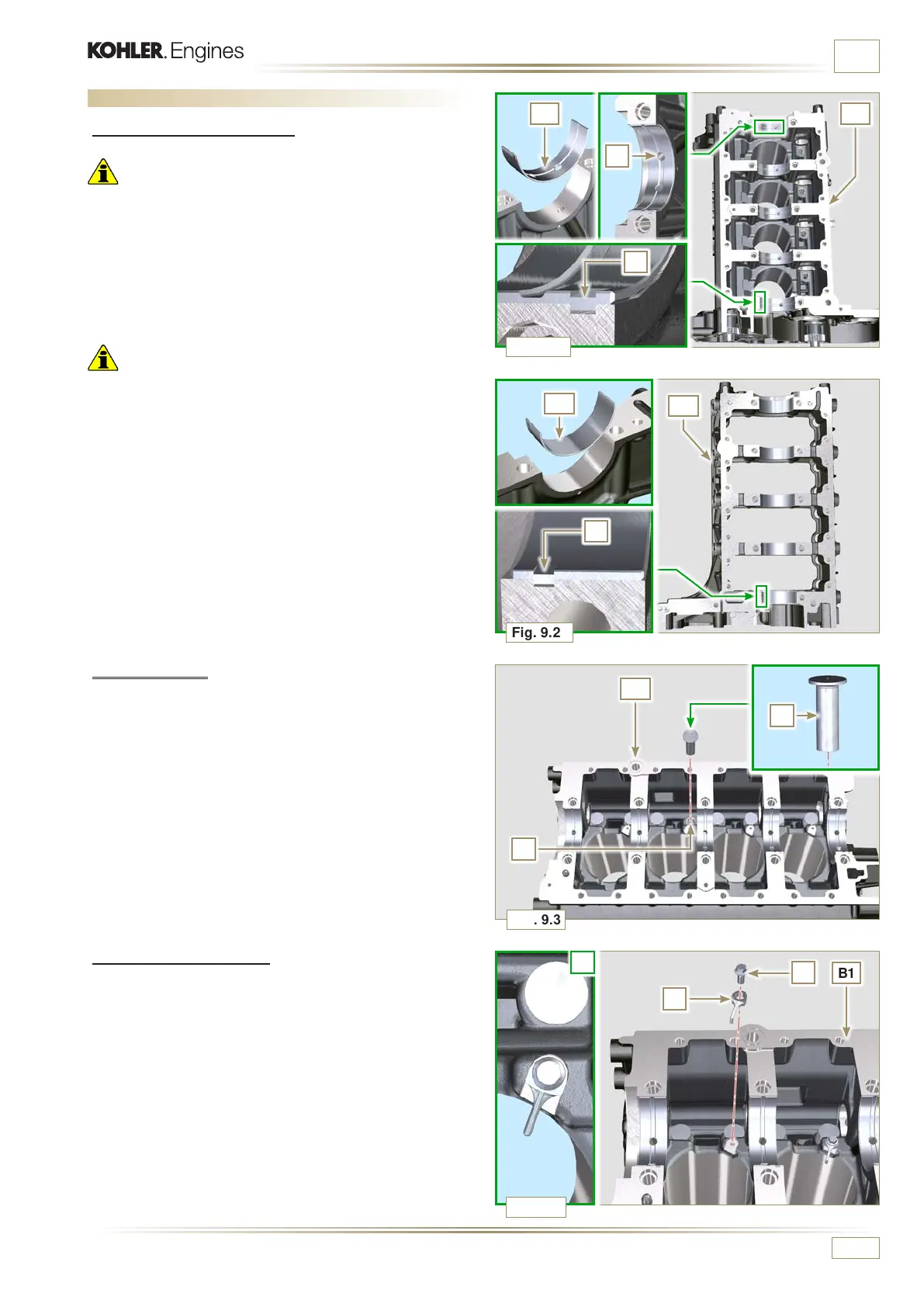

B1

A2

Fig. 9.4

Fig. 9.3

Fig. 9.1

C

F

A1

D

B1

B1

E

B1

L

H

G

ED0053030410

ASSEMBLY INFORMATION

2 - Fit the new half-bearings A2 onto the lower crankcase B2

using the reference notches C.

3 - Lubricate the half-bearings A1 and A2 with oil.

9.3.2 Tappets

1 - Lubricate the tappets E with oil.

2 - Insert the tappets E into the housings F of the upper

crankcase B1.

9.3 Engine block assembly

9.3.1 Crankshaft bushings

Important

• Execute the procedure in Par. 8.2.1 and 8.2.2, before

proceeding with assembly.

• The crankshaft half-bearings are made of special material.

Therefore, they must be replaced every time they are

assembled to prevent seizures.

1 - Fit the new half-bearings A1 onto the crankcase upper half

B1 adhering to the reference notches C.

Important

• After the half-bearings are fitted, check that the lubrication

holes D correspond with the crankcase grooves B1.

• The lower and upper half bearings CANNOT be singularly

replaced, and both halves must be replaced together.

9.3.3 Oil spray nozzles

1 - Insert the sprayers G onto the upper crankcase B1

manually screwing the screw fittings H.

2 - Ensure that the spray nozzles G are inserted correctly in

their seat, as shown in detail L and tighten the connecting

screws H (tightening torque of 10 Nm).

Loading...

Loading...