48

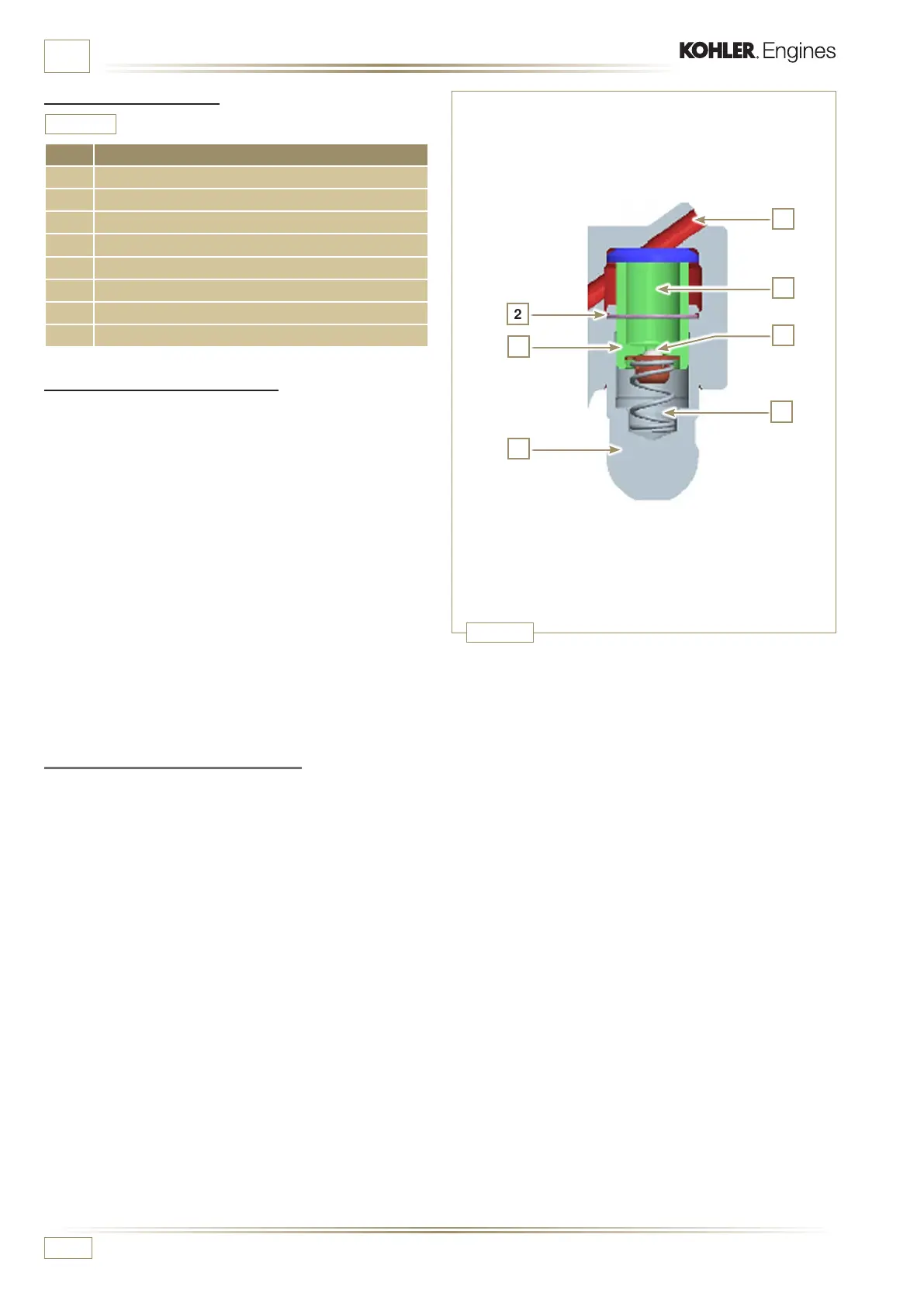

Fig. 2.54

A

B

1

2

3

4

5

Tab. 2.44

ED0053030410

TECHNICAL INFORMATION

2.16.5 Hydraulic tappets

POS. DESCRIPTION

A Low pressure chamber

B Hight pressure chamber

1 Hydraulic tappets oil rell pipe

2 Retaining ring

3 Piston

4 Unidirectional valve

5 Tappet body

6 Spring

2.16.5.1 Hydraulic tappet operation

The operating principle of the hydraulic tappet is based on the

incompressibility of the liquids and on controlled leakage.

The oil under pressure enters the tappet chamber A,

providing a constant supply of oil in the low-pressure

chamber.

Through the non-return valve, 4 the oil can only access the

high-pressure chamber B and exit via the clearance between

the piston 3 and the tappet body 5 (controlled leakage).

The chamber B is lled when the rocker arm is on the base

radius of the cam and the spring 6 keeps the piston 3 against

the valve stem, thus eliminating any system play. Thanks

to the spring extension, the tappet "extends", creating a

small depression in the chamber B, making the non-return

valve 4 open, and allowing the oil in the chamber A to pass

to chamber B, restoring the proper amount of oil required to

eliminate any play in the valves.

2.16.5.2 Difcult operating conditions:

For proper operation of the hydraulic tappets is essential that

the low pressure chamber of the piston 3 is always full of oil.

In some conditions this may not occur (due to the fact that oil

leaks, when the engine is switched off, can also partially drain

the tappets): this situation will result in play that will occur with

a typical noise similar to ticking, not to be confused with the

normal ticking of the injectors.

1 - When the engine is cold, the tappet filling time could be

very long if the oil used is not suitable for the specific

environmental conditions (Tab. 2.2).

2 - If the engine is very hot: at idle speed, oil pressure may

be low, and small air bubbles could form in the circuit.

Because of this, this compressing the tappet slightly and

producing valve play which is responsible for the ticking

sound. On account of this, the tappet compresses slightly

giving rise to a valve clearance, thus generating a slight

ticking sound, which however disappears rapidly (MAX

10 seconds) once normal operating conditions have been

restored.

Anyway the duration of ticking Anyway the duration of ticking

sound must be MAX 30 seconds. If not, the problem is surely

due to the poor quality of the oil, wear or impurities that,

transported by the oil, can inltrate between the ball valve

and its seat inside the piston, compromising the operation of

the tappet itself; In these cases, the only solution is to replace

the oil or hydraulic tappets.

The prolonged persistence of the ticking sound or abnormal

noise must be investigating in order to prevent any malfunctions;

if necessary, replace the hydraulic tappets and engine oil.

Loading...

Loading...