7

103

_07

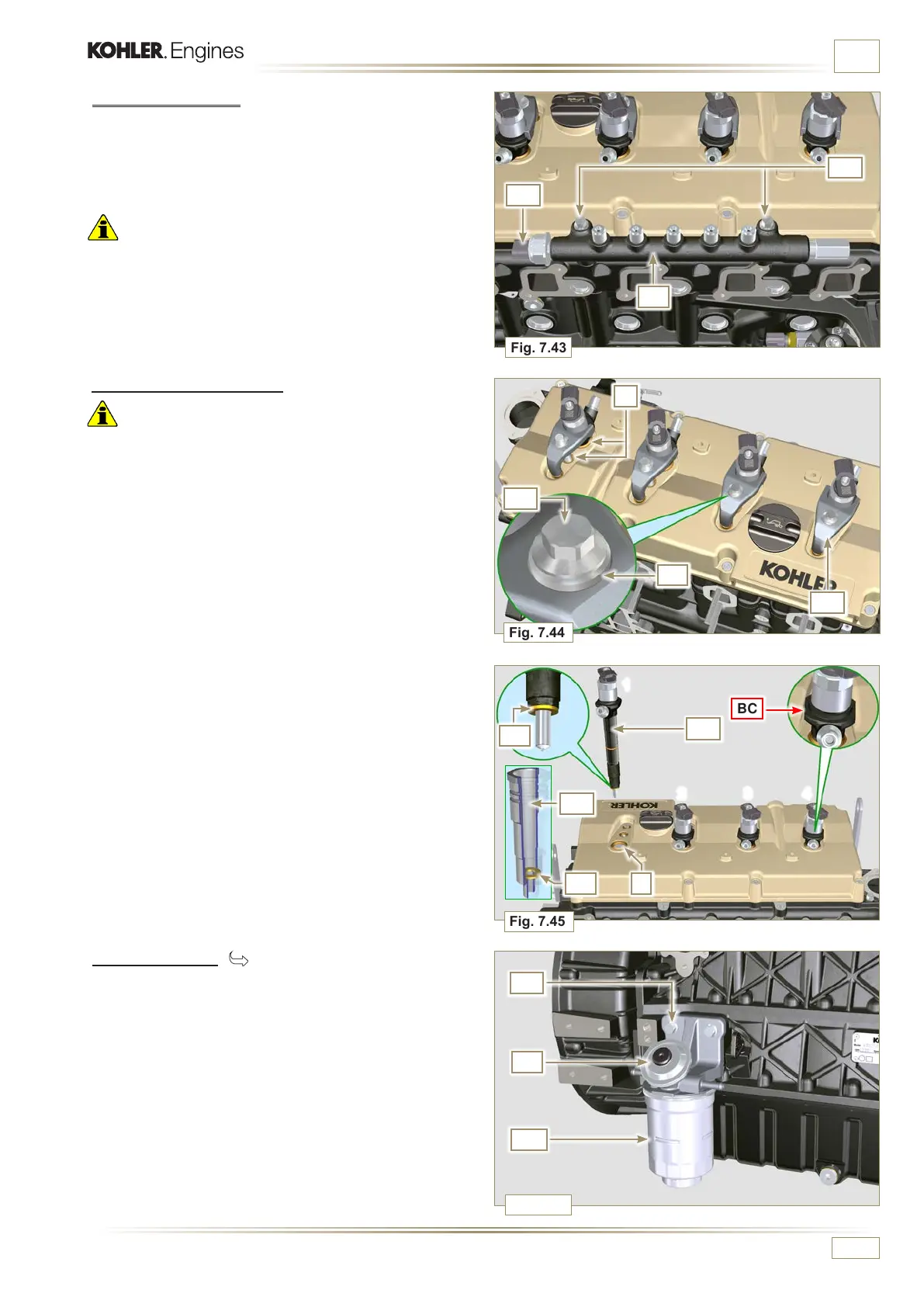

Fig. 7.43

AC

AB

AD

Fig. 7.44

AE

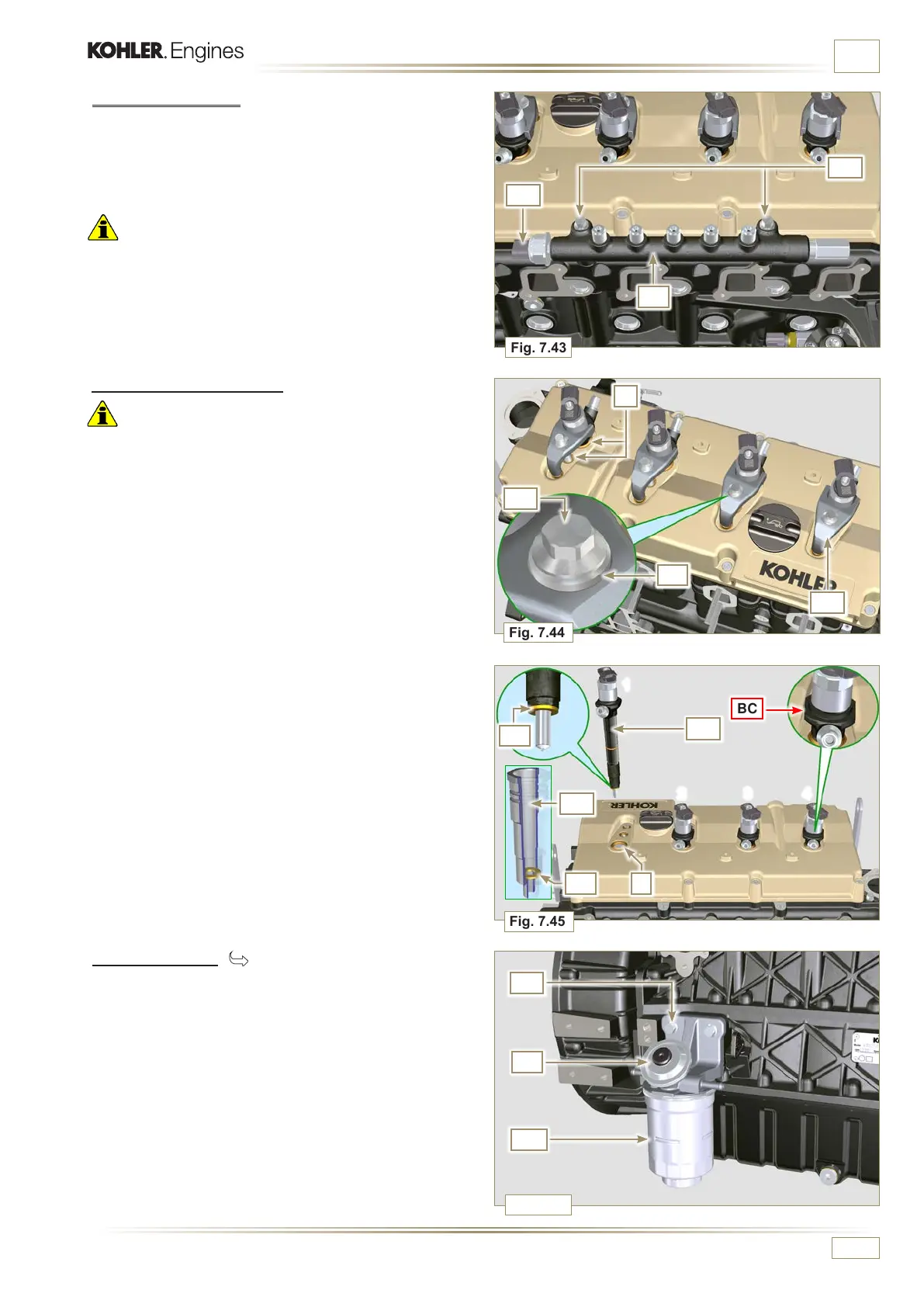

Fig. 7.45

AL

AM

X

Fig. 7.46

1

2 3 4

AN

AP

AW

AF

AG

X

BC

AH

AL

ED0053029590

INFORMATION FOR DISASSEMBLY

7.10.4 Common rail

1 - Undo the screws AB and remove the Common Rail AC.

NOTE: Take care to protect te sensor AD f r o m k n o c k s , m o i s t u r e

and any high temperature source. The internal parts of

the rail cannot be repaired.

Important

• Seal all injection component unions as illustrated in

Para 2.9.8.

• Il Common Rail non è riparabile.

7.10.5 Electronic injectors

Important

• In the event that the electronic injectors are disassembled (not

necessarily replaced), mark them with the relevant cylinder

number from which they originate so as not to confuse them

during re-assembly (Fig. 7.45).

• The electronic injectors cannot be repaired.

• If one or more electronic injectors are to be replaced, the new

calibration data must be inserted in the ECU via a specific

instrument (ST_01).

• Be careful not to damage the gaskets X.

1 -

Undo capscrews AE and remove them together with the

relative washers AF and then brace AG.

2 -

Pull out the electronic injector AH.

NOTE: Should you be unable to remove the electronic injector

(acting only on point BC), use an open-ended spanner

(Ã 34 mm), by applying small rotations to unblock the

component.

3 -

Seal all injection component unions as illustrated in

Par. 2.9.8.

4 -

Ensure that gasket AL has remained in the correct position

(Fig. 7.45).

Otherwise, recover the gasket from inside the electronic

injector AM.

7.10.6 Fuel lter ( )

1 - Undo the fuel cartridge AW from support AP.

2 - Undo the screws AN and remove the filter support AP.

Loading...

Loading...