7

102

_07

A

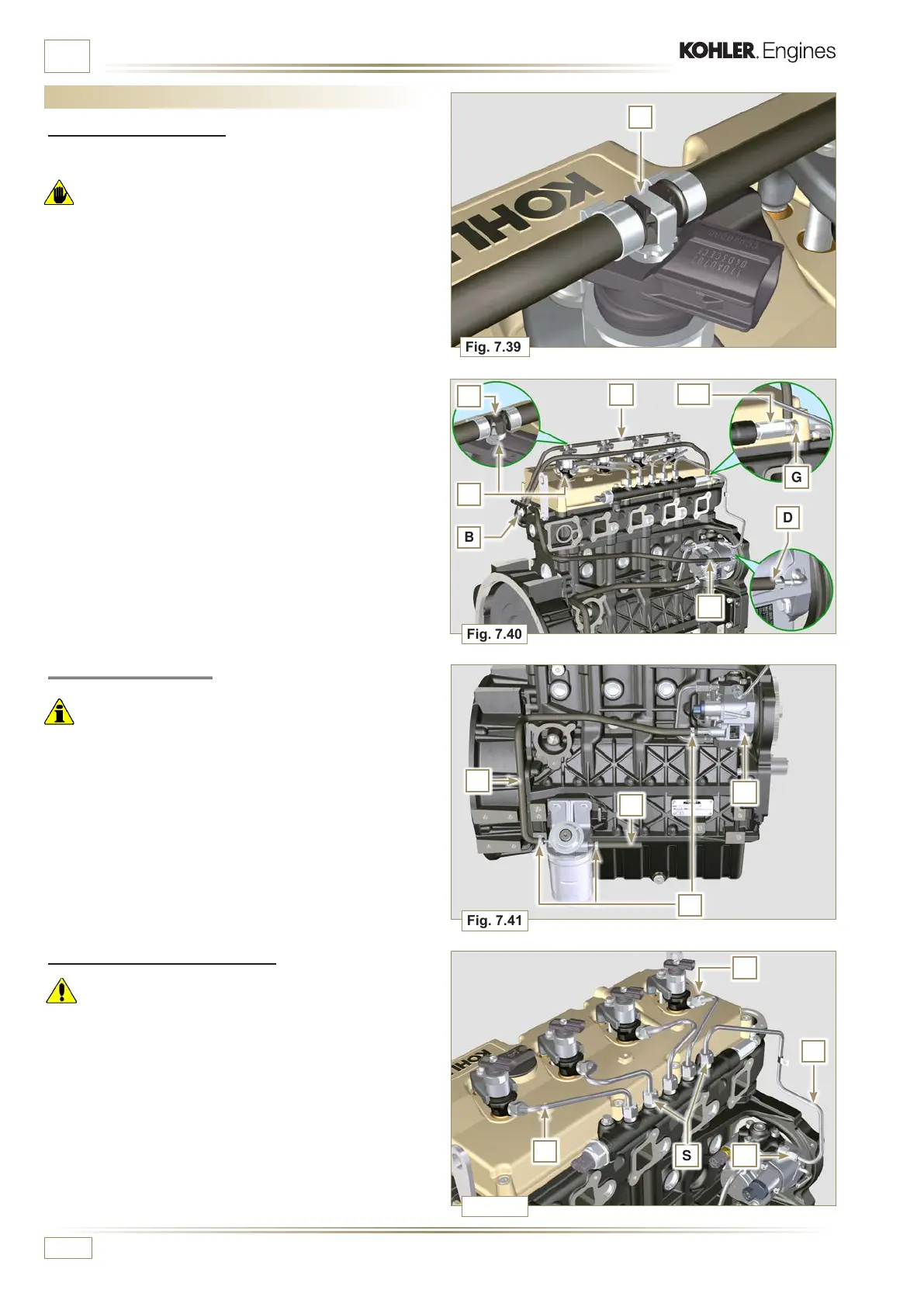

Fig. 7.39

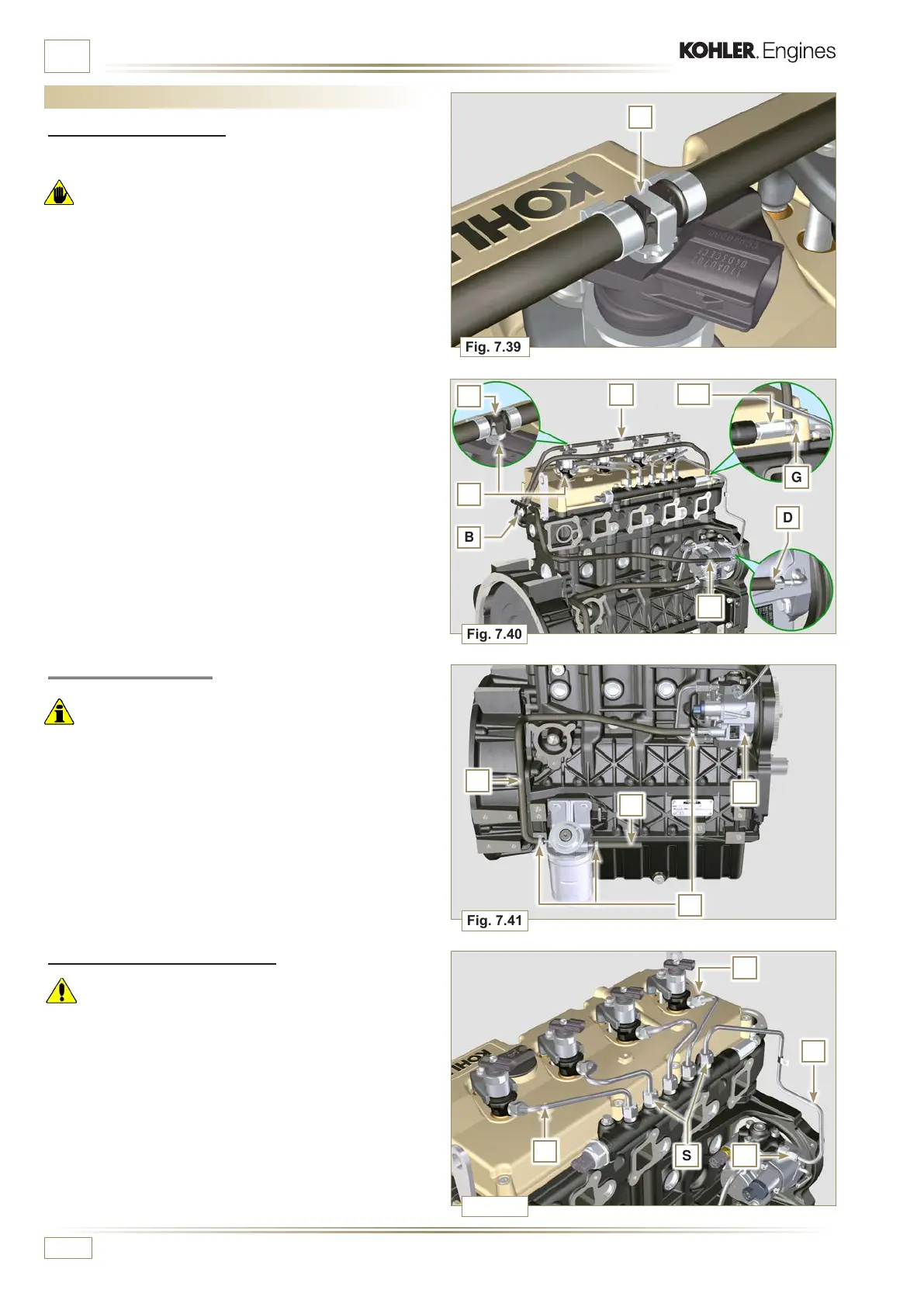

Fig. 7.40

M

B

D

E

G

N

Fig. 7.41

D

Q

R

P

Fig. 7.42

S

V

U

T

T

A

AA

ED0053029590

INFORMATION FOR DISASSEMBLY

7.10 Fuel system disassembly

7.10.1 Fuel return pipes

1 - Release the clips A.

Warning

• After removing the unions, the clips A must automatically

return to their initial position; otherwise they must be replaced.

2 - Undo the B distributor return fixing capscrew.

3 - Release the clamp D.

4 - Disconnect the pipe E from the fuel return fitting.

5 - Undo and remove the screw G with the relative gaskets

and put the cap on the Common Rail pressure relief valve

AA.

6 - Disconnect unions M from electronic injectors N.

7 - Remove the fuel return pipes.

7.10.2 Fuel ow pipes

Important

• Seal all openings of the inlet and return unions on the injection

pump D with the relevant caps, in order to prevent impurities

from entering.

1 - Loosen the clamps P.

2 - Remove the pipes Q and R.

7.10.3 High pressure fuel pipes

Danger

• The fuel injection circuit undergoes high pressure, use safety

protections as described in Para 3.4.3.

• Ensure that the Common Rail is not under pressure by slowly

and carefully unscrewing one of the nuts S.

1 -

Loosen the nuts S and T in sequence.

2 - Fully undo the nuts S and T in sequence, and remove the

high pressure pipes U and V.

Loading...

Loading...