117

8

_07

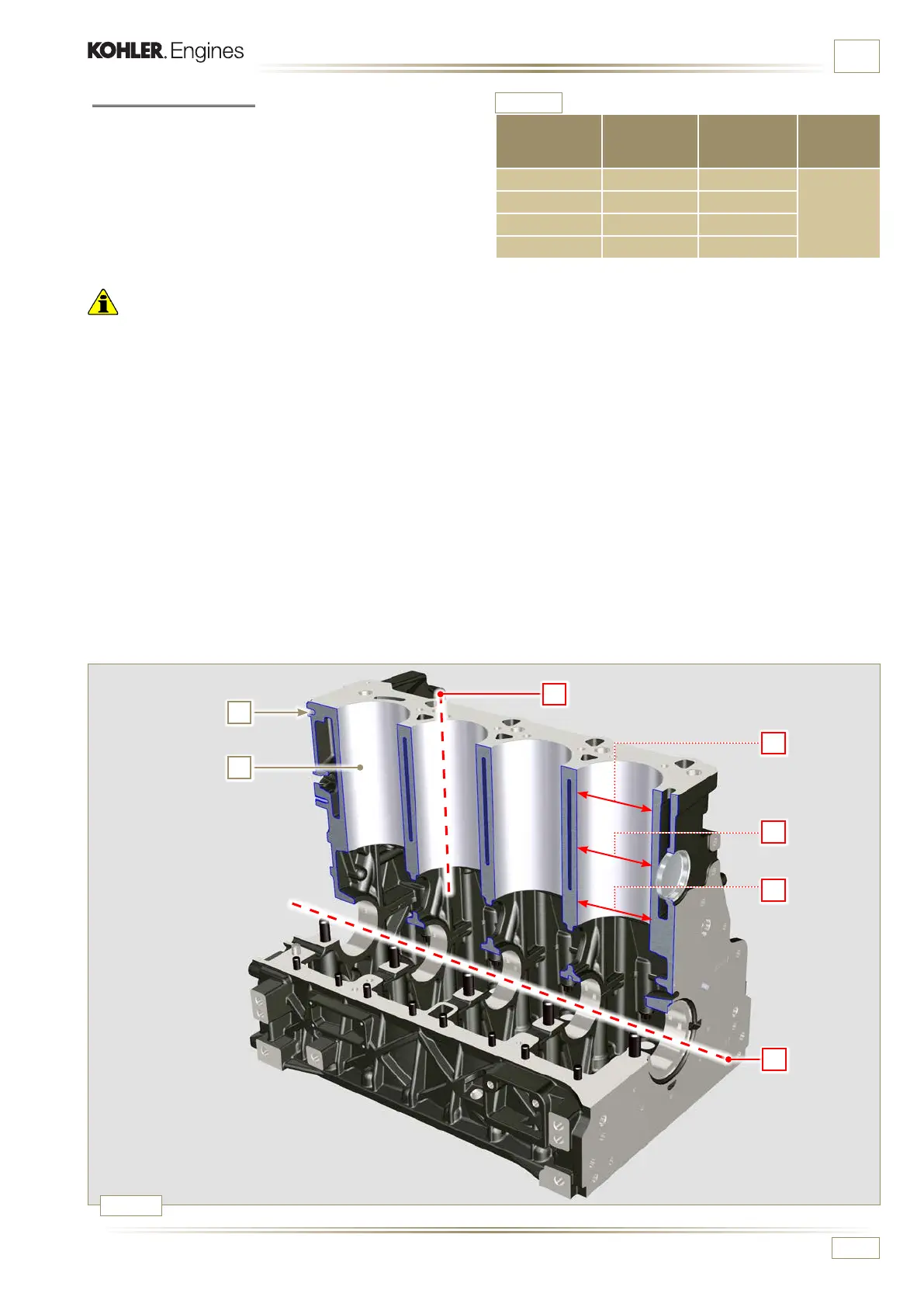

J

M

N

F

G

H

L

Fig. 8.2

ED0053029590

INFORMATION ABOUT OVERHAULING

8.2.2 Cylinder check

Position crankcase G onto a workbench.

With a dial gauge, measure the diameter in correspondence to

points J-M-N (Fig. 8.2) lengthwise and diagonally with regard

to axis H of the crankshaft.

If ovalisation or wear detected in a single point in J-M-N is

greater than +0.05 mm with regard to the value in Ta b . 8 .1 a , y o u

are required to perform grinding operations on all cylinders F.

Refer to Ta b. 8 .1a to estab l ish the cleara nc e valu e of cylin d er s

subjected to grinding operations.

Importante

• Grinding is prohibited before 10000 h of operation on all

engines provided with an EPA name plate (refer to Par. 1.3).

• The grinding involved is of +0.20, +0.50 and + 1 mm.

• Cylinder grinding operations must observe KOHLER

SPECIFICATIONS - cod. ED0035612500.

• Grinding must be strictly performed on all cylinders F.

Ta b . 8 .1 a d e t a i l s t h e d i m e n s i o n a l v a l u e s o f n e w c o m p o n e n t s o n l y.

(1)

The increase of +0.20 mm, may already be present on the

engine.

Tab. 8.1a

Grinding values

PISTON

Ø CYLINDER

(± 0.007 mm)

Ø PISTON

(± 0.007 mm)

CLEARANCE

VALUE (mm)

STD 88.010 87.950

0.046 - 0.074

+0.20

(1)

88.210 88.150

+0.50 88.510 88.450

+1.00 89.010 88.950

Loading...

Loading...