6

71

_07

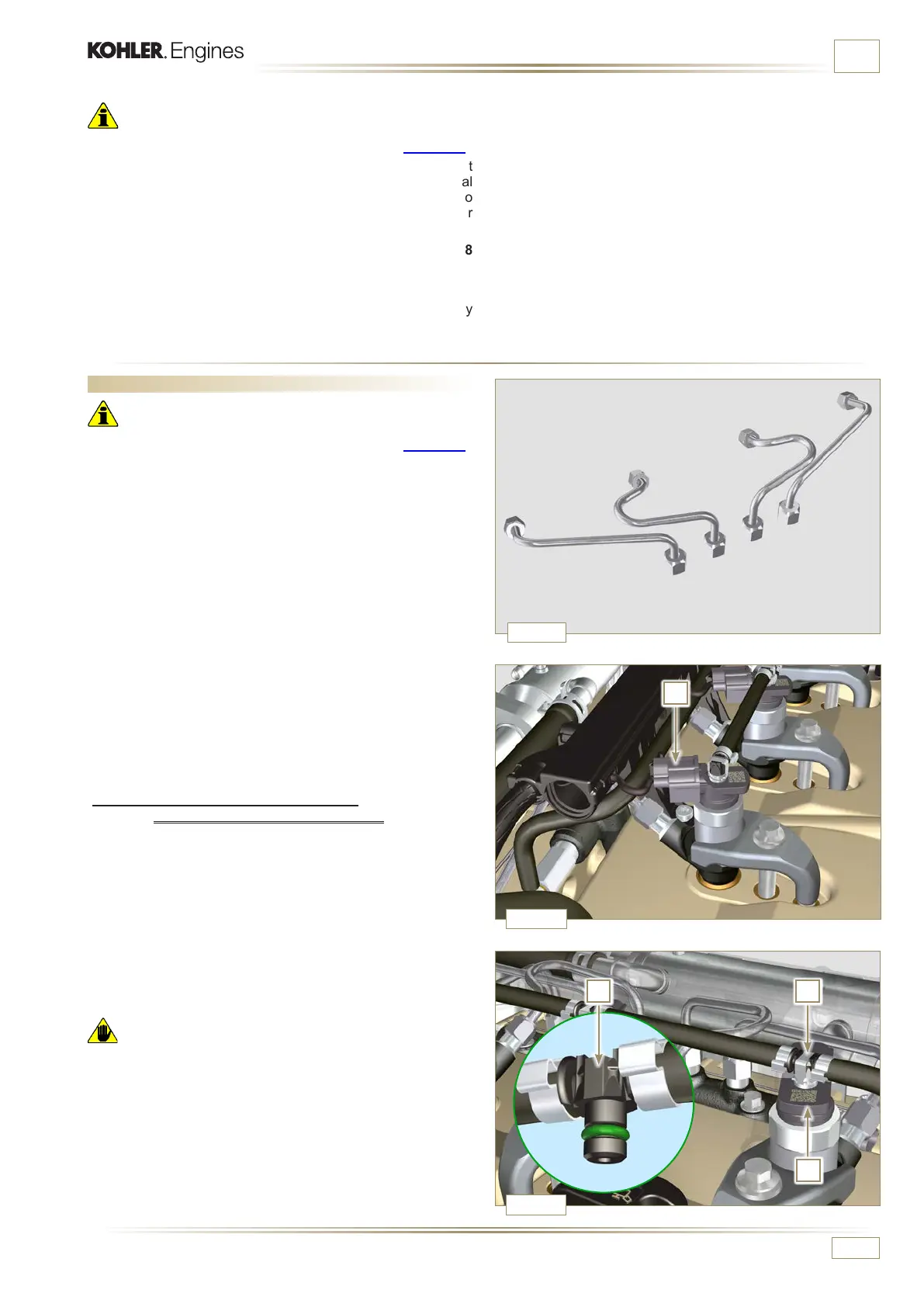

Fig. 6.3

E

F

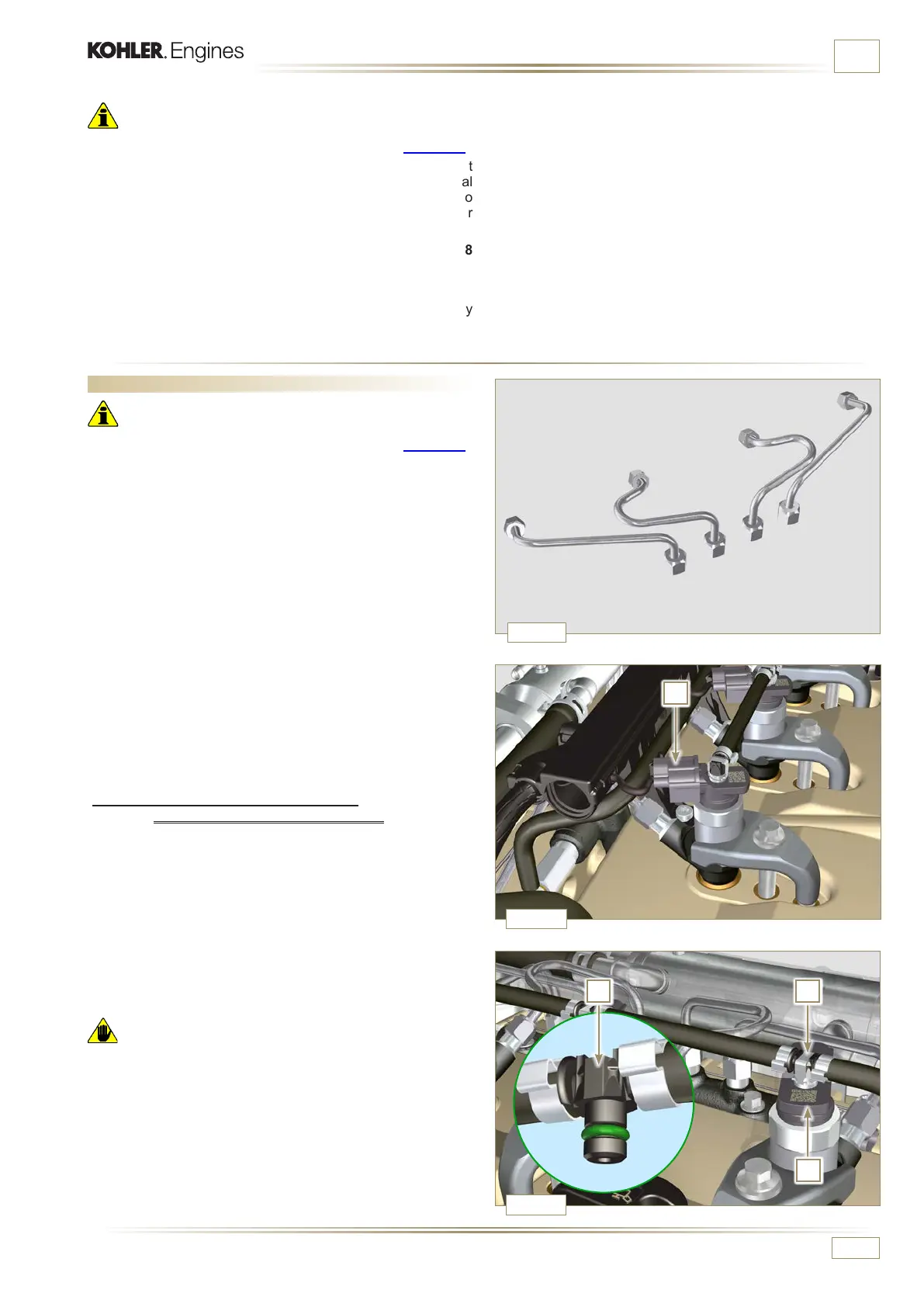

Fig. 6.2

C

G

Fig. 6.1

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

Important

• Before proceeding with operation, carefully read Par. 3.3.2

• In the event of the electronic injectors being disassembled (not

necessarily replaced) their position with respect to individual

cylinders must not be changed when re-assembled. Refer to

the reference between each injector and respective cylinder

number.

• Seal all injection component unions as illustrated in P a r. 2 . 9. 8

during disassembly.

• Handle the components as described in Par. 2.18.

• The high pressure pipes must be replaced every time they

are disassembled.

• After disassembly, protect the sensor against shocks,

dampness and any high temperature sources.

• Replace all seal gaskets after each assembly for all

components on which they are provided.

NOTE: In the event of a leak upon replacement (oil - coolant

- fuel - air), do not intervene with the engine running,

but stop it and wait for 5/10 minutes before checking

and solving the problem.

6.1.1 Fuel return pipes disassembly

(Common Rail/electronic injectors)

1 - Disconnect the connector C.

2 -

Remove clips E from the electronic injector F.

3 - Disconnect the junction G from the electronic injector F.

Warning

• After removing the fittings, the clips E must automatically

return to their initial position; otherwise they must be replaced.

4 - Seal all injection component unions as illustrated in

Par. 2.9.8.

6.1 Electronic injector replacement

Important

• Before proceeding with operation, carefully read Par. 3.3.2.

• Always replace the high pressure pipes after each

disassembly.

• Before disassembling the electronic injectors, make sure the

new high pressure pipes are available.

• If a new (or different) electronic injector is fitted on the engine,

the new calibration data must be entered in the ECU via a

specific instrument (ST_01).

• Electronic injectors are not repairable.

• This procedure may be performed on one or more electronic

injectors.

Loading...

Loading...