6

72

_07

M NF

L

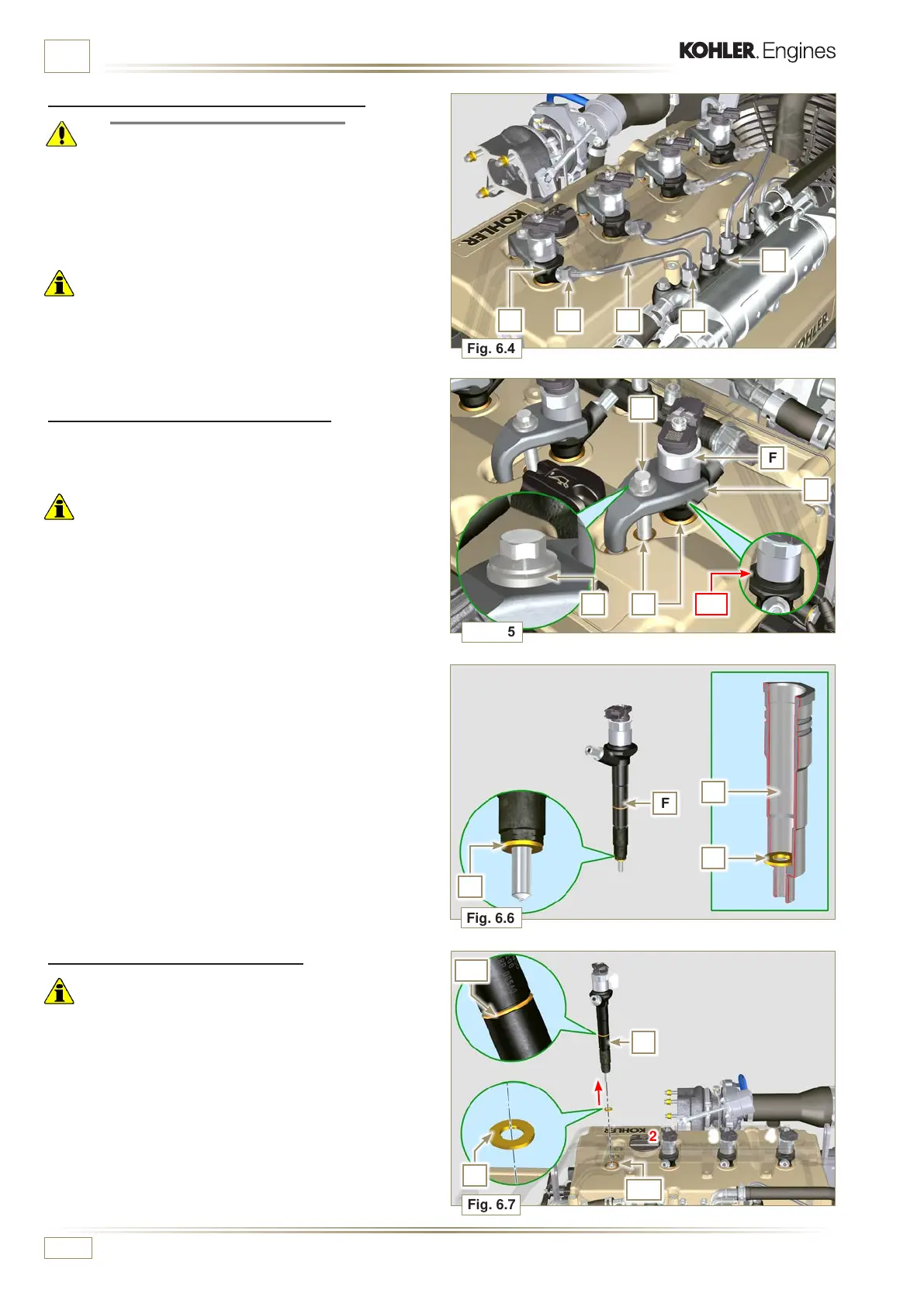

Fig. 6.4

1

2

3

4

H

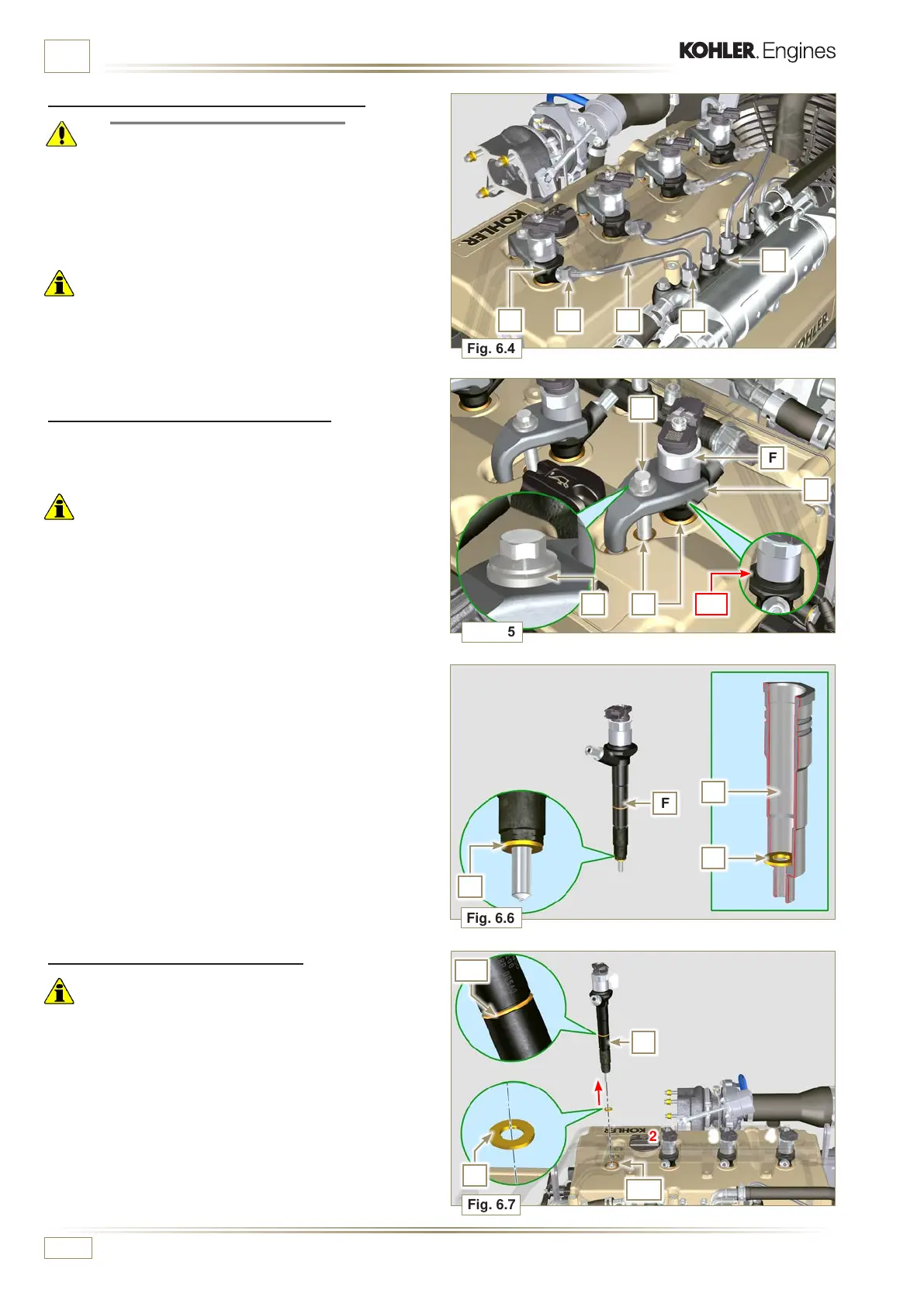

Fig. 6.6

S

Fig. 6.5

P

F

Q

R

F

T

S

Fig. 6.7

AA

F

S

2

3

4

1

X

AB

BC

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.1.2 High pressure fuel pipes disassembly

(Common Rail/electronic injectors)

Danger

• The fuel injection circuit is under high pressure, use safety

protections as described in Par 3.4.3.

• Ensure that the Common Rail is not under pressure by slowly

and carefully unscrewing one of the nuts H.

1 -

Undo the nut H on the Common Rail L and then the nut M

on the electronic injector F and remove the pipe N.

Important

• In the event that the electronic injectors are disassembled (not

necessarily replaced), mark them with the relevant cylinder

number from which they originate so as not to confuse them

during re-assembly.

• Seal all injection component unions as illustrated in P a r. 2 . 9 . 8 .

6.1.3 Electronic injectors disassembly

1 - Undo and remove capscrew P with washer R and then

brace Q.

Important

• Be careful not to damage the gaskets X.

• Replace rings X, if damaged.

2 - Pull out the electronic injector F.

NOTE: Should you be unable to remove the electronic injector

(acting only on point BC), use an open-ended spanner

(Ã 34 mm), by applying small rotations to unblock the

component.

3 -

Seal all injection component unions as illustrated in Par.

2.9.8.

4 -

Ensure that gasket S has remained in the correct position

(Fig. 6.6). Otherwise, recover the gasket from inside the

electronic injector T manifold.

6.1.4 Electronic injector assembly

Important

• Always replace and lubricate the gaskets AA and S of the

electronic injectors F with fuel, every time they are replaced.

• Reposition the electronic injectors (not replaced) by following

the references made for disassembly, as indicated in

Par. 6.1.2.

1 -

Insert the gasket S on the electronic injectors F (Fig. 6.7).

2 -

Insert electronic injector F into manifold T, being extra

careful not to damage gasket AB and direct it as indicated

in Fig. 6.7.

Loading...

Loading...