6

73

_07

P

Q

R

AD

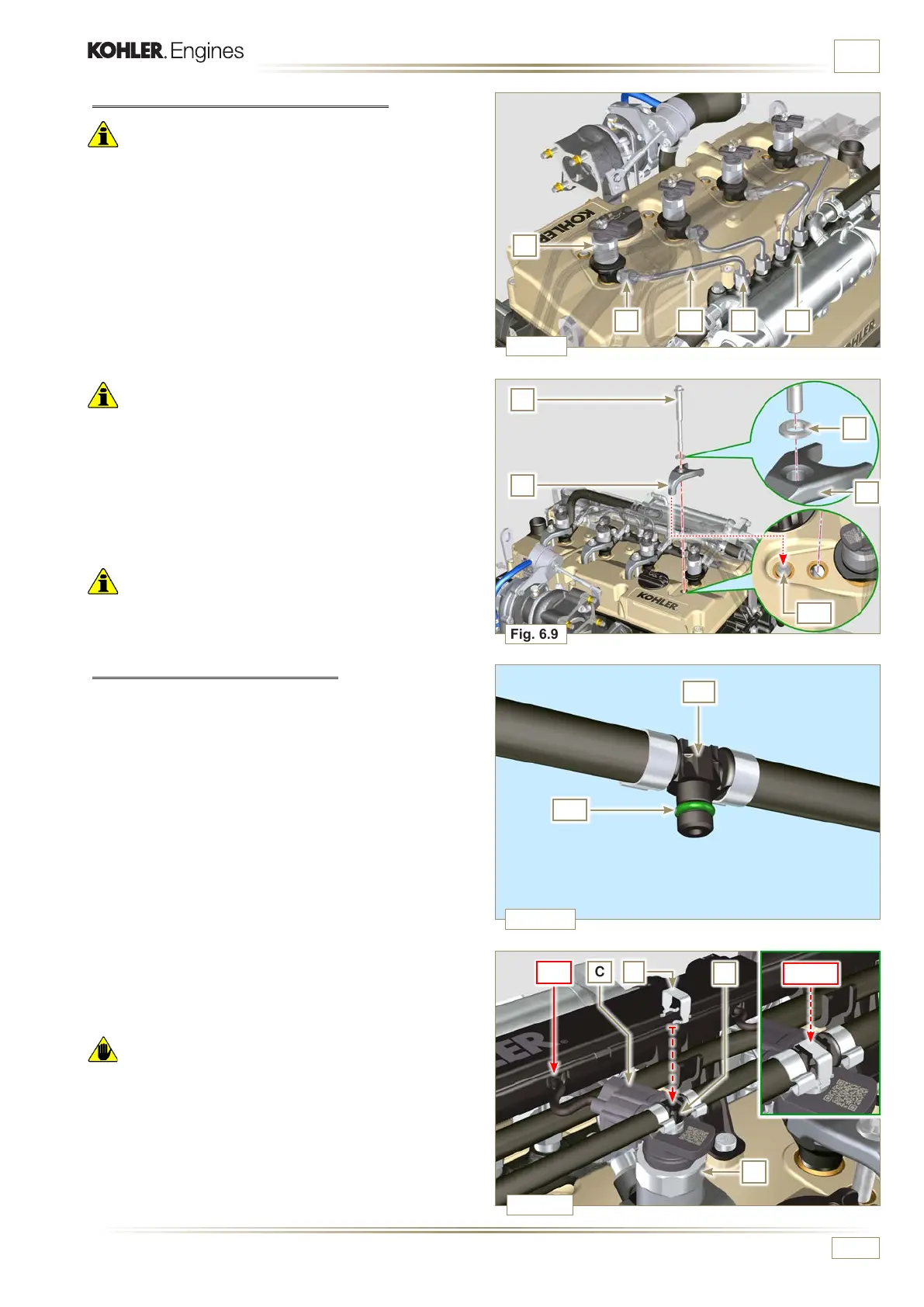

Fig. 6.9

Fig. 6.8

N HM L

F

Fig. 6.10

G

AE

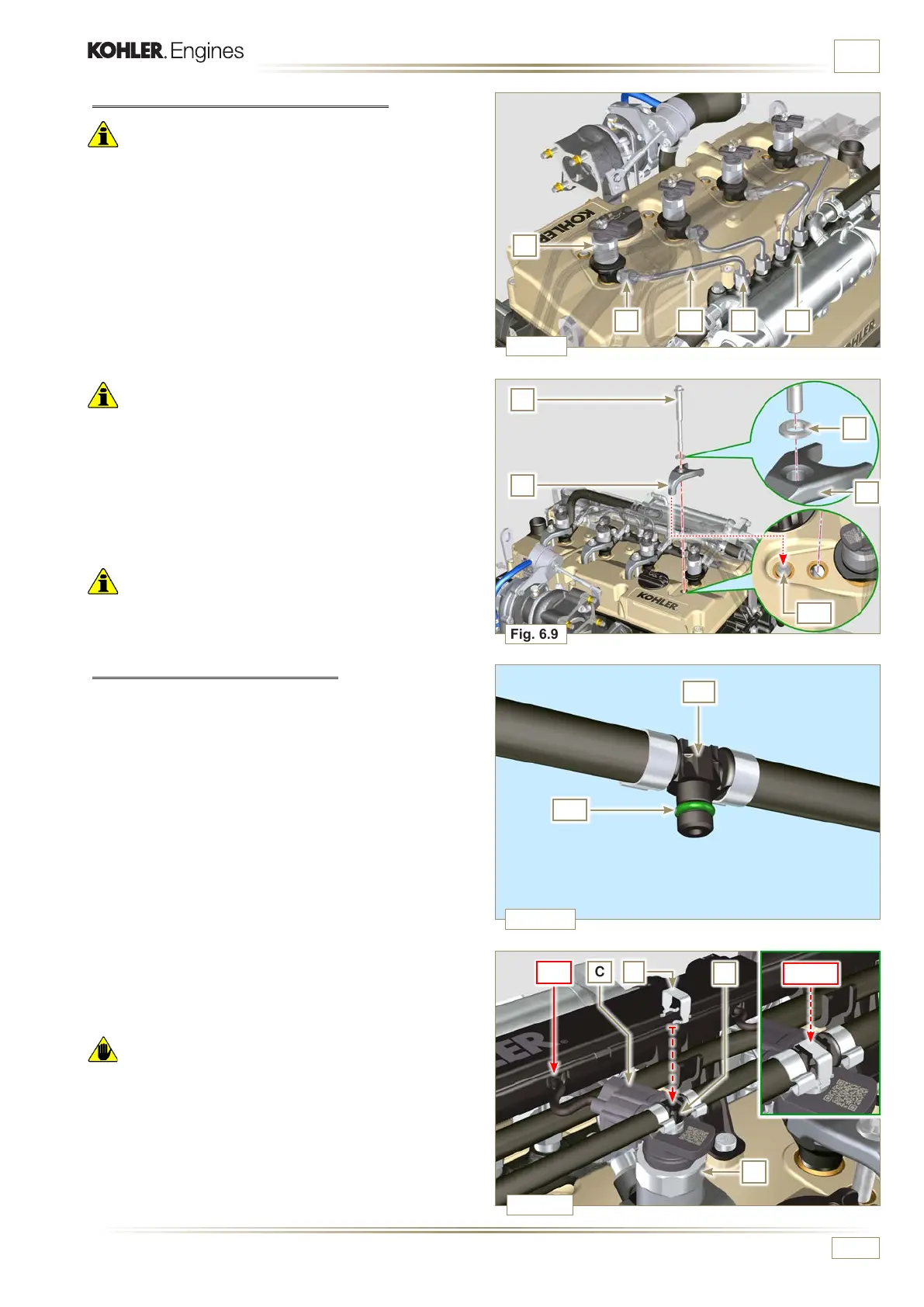

Fig. 6.11

F

C

AF

G

E

CLICK

S

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.1.5 High pressure fuel pipes assembly

Important

• Always replace the pipes N after each assembly.

1 -

Position tube N in the Common Rail seat of the electronic

injector; correct the position of the electronic injector by

means of the entrance of the electronic injector unions F

and Common Rail L.

2 - Apply the nuts H and M by hand without tightening them.

3 -

Position the fastening brace of electronic injectors Q on

capscrew surface AD, insert capscrews P in brace Q

inserting washer R.

Important

• Ensure that brace S is perfectly positioned onto the electronic

injector.

4 - Tighten the fixing screws P of the electronic injector

bracket (tightening torque at 20 Nm).

5 - Tighten the nut M (tightening torque at 25 Nm).

6 - Tighten the nut H (tightening torque at 30 Nm).

Important

• Replace the pipes N (Fig. 6.8) if the screws P are stiff when

tightened.

6.1.6 Fuel return pipes assembly

1 - Check the condition of the gaskets AE.

2 - Insert unions AF onto electronic injectors F and block them

with clips E.

3 - Mount the connectors C on the electronic injectors F.

Warning

• Slightly move the wiring support to check that there is no

voltage in the electrical wire of connector C in correspondence

with the outlet hole A F.

Loading...

Loading...