Posi-Lock Connecting Rods

The

rod

caps

on

Posi-Lock

connecting

rods

have

a

slight

press

fit

when

assembled.

If

difficulty

in

disassembling

a

Posi-Lockrod

from

the

crankshaft

is

experienced, use

the

following procedure.

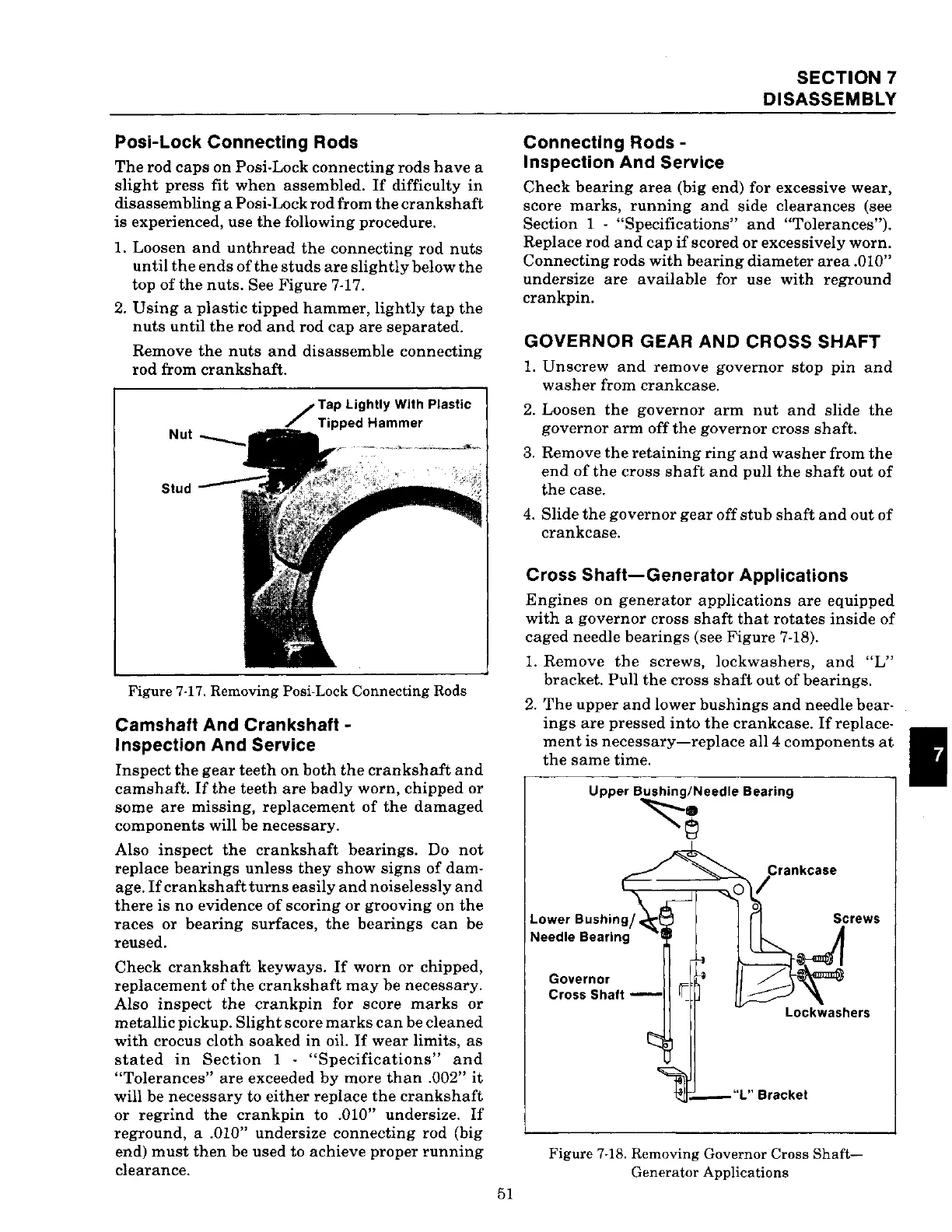

1. Loosen

and

unthread

the

connecting

rod

nuts

until

the

ends

of

the

studs

are

slightly

below

the

top

of

the

nuts.

See

Figure

7-17.

2.

Using

a

plastic

tipped

hammer,

lightly

tap

the

nuts

until

the

rod

and

rod

cap

are

separated.

Remove

the

nuts

and

disassemble

connecting

rod

from

crankshaft.

Tap

Lightly

With

Plastic

Nut

Stud

Figure 7-17. Removing Posi-Lock Connecting Rods

Camshaft And Crankshaft -

Inspection And Service

Inspect

the

gear

teeth

on

both

the

crankshaft

and

camshaft.

If

the

teeth

are

badly

worn,

chipped

or

some

are

missing,

replacement

of

the

damaged

components

will

be

necessary.

Also

inspect

the

crankshaft

bearings.

Do

not

replace

bearings

unless

they

show

signs

of

dam-

age.

If

crankshaft

turns

easily

and

noiselessly

and

there

is

no

evidence

of

scoring

or

grooving

on

the

races

or

bearing

surfaces,

the

bearings

can

be

reused.

Check

crankshaft

keyways.

If

worn

or

chipped,

replacement

of

the

crankshaft

may

be

necessary.

Also

inspect

the

crankpin

for score

marks

or

metallic

pickup.

Slight

score

marks

can

be

cleaned

with

crocus

cloth

soaked

in

oil.

If

wear

limits,

as

stated

in

Section

1 -

"Specifications"

and

"Tolerances"

are

exceeded

by

more

than

.002"

it

will

be

necessary

to

either

replace

the

crankshaft

or

regrind

the

crankpin

to .010" undersize.

If

reground,

a .010"

undersize

connecting

rod (big

end)

must

then

be used to

achieve

proper

running

clearance.

51

Connecting

Rods-

Inspection And Service

SECTION

7

DISASSEMBLY

Check

bearing

area

(big end) for excessive

wear,

score

marks,

running

and

side

clearances

(see

Section 1 - "Specifications" and "Tolerances").

Replace

rod

and

cap

if

scored

or

excessively

worn.

Connecting

rods

with

bearing

diameter

area

.010"

undersize

are

available

for use

with

reground

crankpin.

GOVERNOR GEAR AND CROSS SHAFT

1.

Unscrew

and

remove

governor

stop

pin

and

washer

from

crankcase.

2.

Loosen

the

governor

arm

nut

and

slide

the

governor

arm

off

the

governor

cross

shaft.

3.

Remove

the

retaining

ring

and

washer

from

the

end

of

the

cross

shaft

and

pull

the

shaft

out

of

the

case.

4.

Slide

the

governor

gear

off

stub

shaft

and

out

of

crankcase.

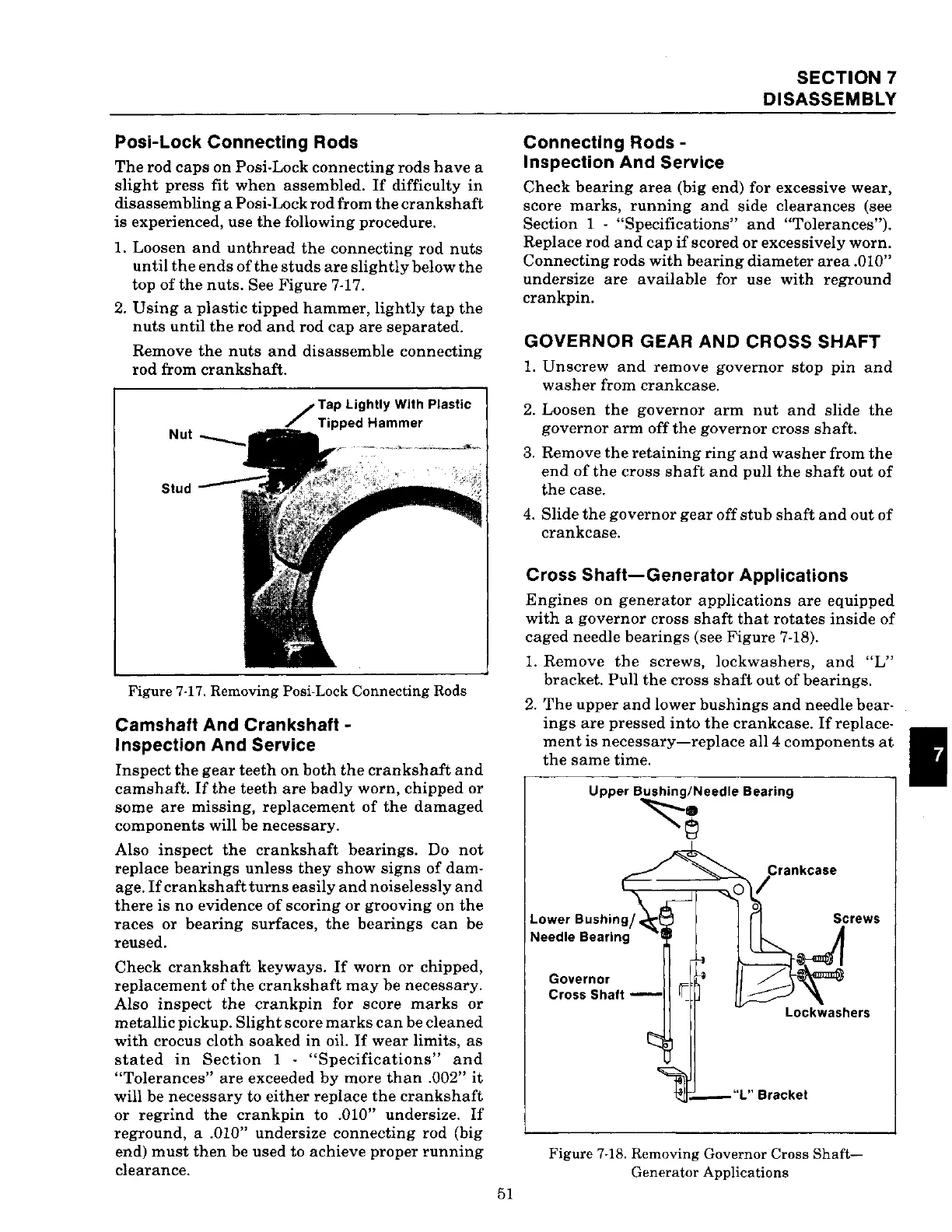

Cross

Shaft-Generator

Applications

Engines

on

generator

applications

are

equipped

with

a

governor

cross

shaft

that

rotates

inside

of

caged

needle

bearings

(see

Figure

7-18).

1.

Remove

the

screws,

lockwashers,

and

"L"

bracket.

Pull

the

cross

shaft

out

of

bearings.

2.

The

upper

and

lower

bushings

and

needle

bear-

ings

are

pressed

into

the

crankcase.

If

replace-

ment

is

necessary-replace

all4

components

at

the

same

time.

Upper

Bushing/Needle

Bearing

~~

Lower

Bushingj

Needle Bearing

Governor

Cross Shaft -

Lockwashers

Figure 7-18. Removing Governor Cross

Shaft-

Generator Applications

Loading...

Loading...