TP-6881 7/15 103Section 5 Component Testing and Adjustment

5.16 Continuity Checks

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Moving parts.

WARNING

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

Testing live electrical circuits. Hazardous voltage or

current can cause severe injury or death. Have trained and

qualified personnel take diagnostic measurements of live

circuits. Use adequately rated test equipment with electrically

insulated probes and follow the instructions of the test

equipment manufacturer when performing voltage tests.

Observe the following precautions when performing voltage

tests: (1) Remove all jewelry. (2) Stand on a dry, approved

electrically insulated mat. (3) Do not touch the enclosure or

components inside the enclosure. (4) Be prepared for the

system to operate automatically.

(600 volts and under)

To further check generator set components, disconnect

the battery and remove wiring harness plugs from the

controller circuit board. Use an ohmmeter to check the

continuity of the components listed in Figure 5-37. Also

see Section 7, Wiring Diagrams.

Figure 5-37 gives resistance readings for functional

components. A zero reading on the ohmmeter indicates

continuity. No ohmmeter reading indicates very high

resistance or an open circuit. A measurement that

varies significantly from the value shown in the table

indicates a faulty component; replace faulty

components.

Note: Disconnect the generator set battery before

performing continuity checks to prevent damage

to the ohmmeter.

For rotor and stator resistance and continuity checks,

see Section 5.4, Stator, and Section 5.5, Main Field

(Rotor).

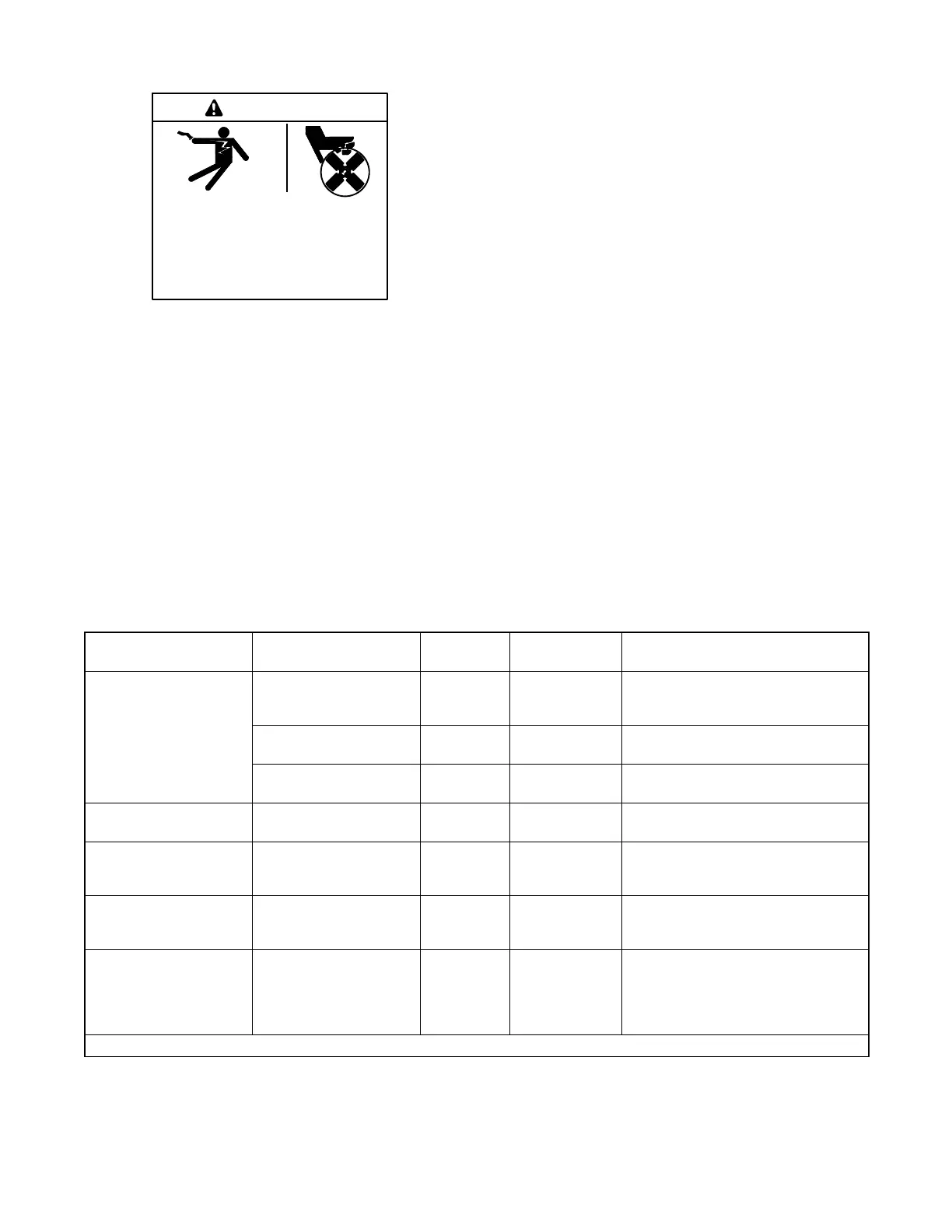

Component

Ohmmeter

Connections

Ohmmeter

Scale

Generator Set

State

Ohmmeter Readings for

Operative Components

P1 wiring harness P1-2 and ground Rx1 OFF Less than 1 ohm (continuity)

Any other reading indicates a poor

ground connection.

P2-6 and P2-7 (stator

leads 11 and 44)

Rx1 OFF Less than 1 ohm (continuity). If no

continuity, check wiring.

P2-3 and P2-4 (stator

leads 55 and 66)

Rx1 OFF Less than 1 ohm (continuity). If no

continuity, check wiring.

Controller wiring P1-1 and battery positive

(+)

R x 100 OFF Less than 1 ohm (continuity). If no

continuity is found, check wiring.

Auxiliary winding breaker

(20-amps)

P2-3 and stator lead 55 R x 100 OFF Less than 1 ohm (continuity). If no

continuity is found, check for an open

circuit.

Low oil pressure (LOP)

switch *

Lead 13 and ground

(engine block)

R x 100 OFF Less than 1 ohm (continuity). No

continuity indicates a faulty switch

and/or wiring.

Temperature sensor

(OTS) *

P1-9 and P1-10 R x 1000 OFF 180--2500 ohms, depending on en-

gine temperature. See Sec-

tion 5.12.2. Less than 1 ohm or an

open circuit indicates faulty wiring or

a faulty sensor.

* See Section 5.12.2, Fault Shutdown Switches

Figure 5-37 Continuity Checks

Loading...

Loading...