TP--6881 7/15 131Appendix

Appendix B Common Hardware Application Guidelines

Use the information below and on the following pages to

identify proper fastening techniques when no specific

reference for reassembly is made.

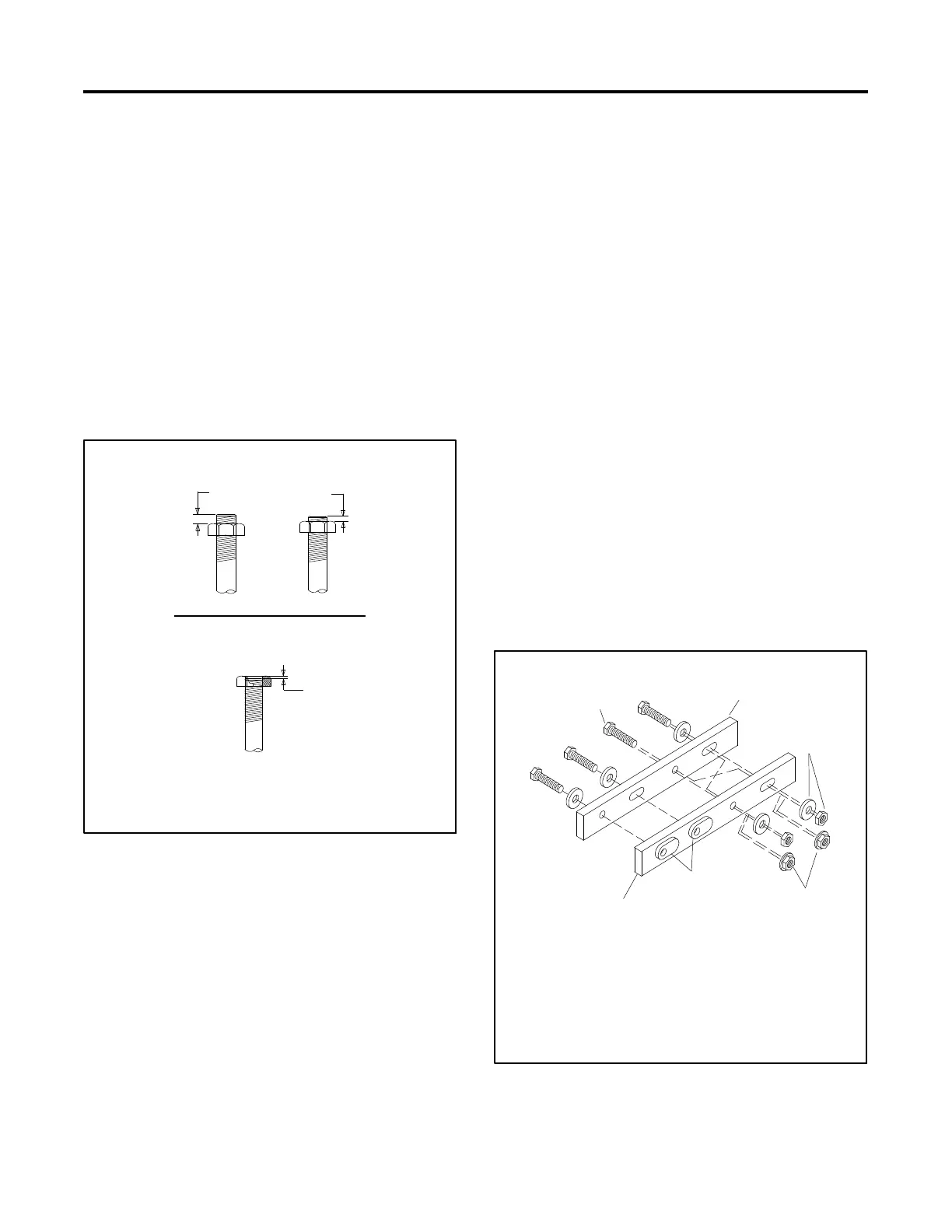

Bolt/Screw Length: When bolt/screw length is not

given, use Figure 1 as a guide. As a general rule, a

minimum length of one thread beyond the nut and a

maximum length of 1/2 the bolt/screw diameter beyond

the nut is the preferred method.

Washers and Nuts: Use split lock washers as a bolt

locking device where specified. Use SAE flat washers

with whiz nuts, spiralock nuts, or standard nuts and

preloading (torque) of the bolt in all other applications.

See Appendix C, General Torque Specifications, and

other torque specifications in the s ervice literature.

G--585

Preferred Nut/Bolt C learance

Unacceptable Nut/Bolt Clearance

1

2

3

1. 1/2 of bolt diameter

2. Min. 1 full thread beyond top of nut

3. Below top of nut

Figure 1 Acceptable Bolt Lengths

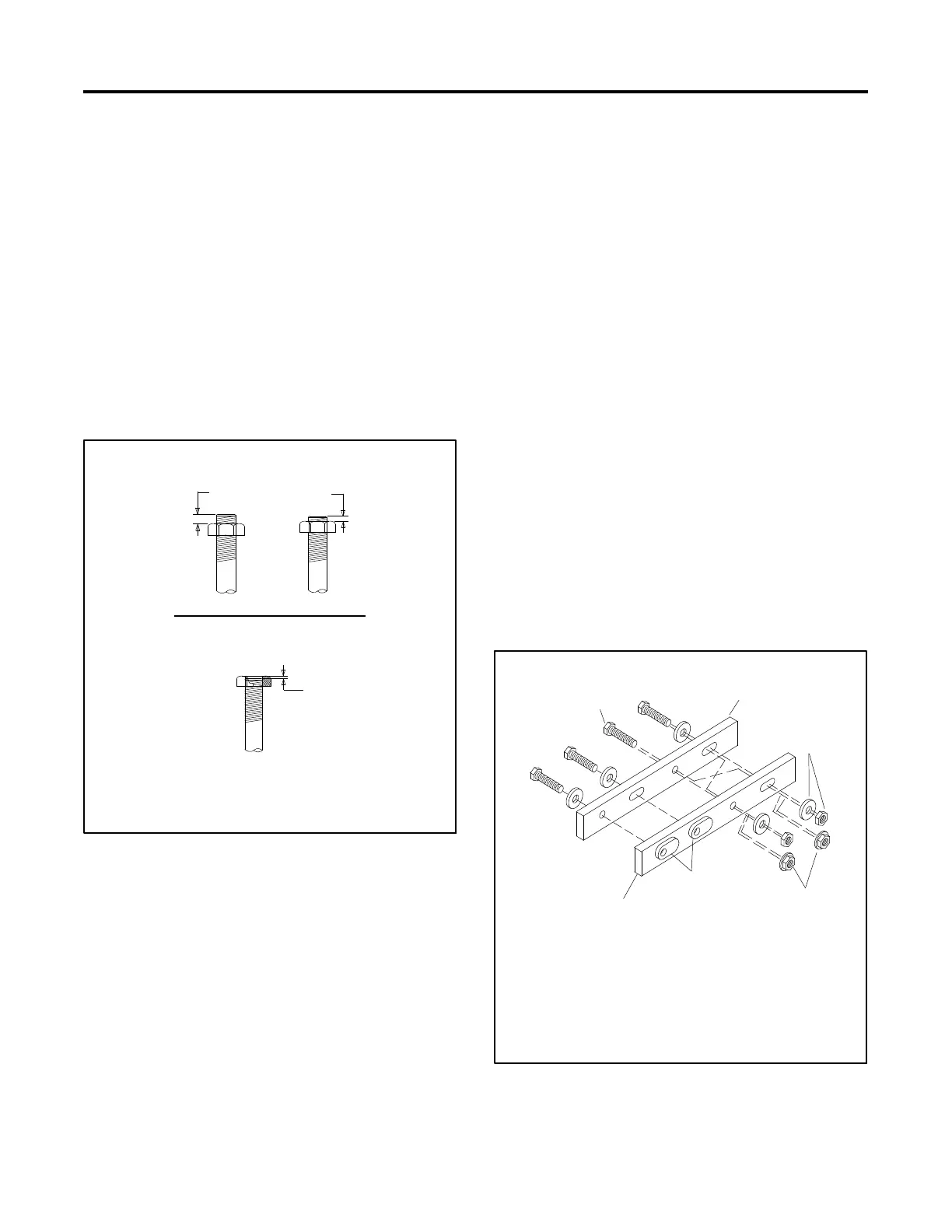

Steps for common hardware application:

1. Determine entry hole type: round or slotted.

2. Determine exit hole type: fixed female thread

(weld nut), round, or slotted.

For round and slotted exit holes, determine if

hardware is greater than 1/2 inch in diameter, or

1/2 inch in diameter or less. Hardware that is

greater than 1/2 inch in diameter takes a standard

nut and SAE washer. Hardware 1/2 inch or less in

diameter can take a properly torqued whiz nut or

spiralock nut. See Figure 2.

3. Follow these SAE washer rules after determining

exit hole type:

a. Always use a washer between hardware and a

slot.

b. Always use a washer under a nut (see 2 above

for exception).

c. Use a washer under a bolt when the female

thread is fixed (weld nut).

4. Refer to Figure 2, which depicts the preceding

hardware configuration possibilities.

G--585

1

2

3

4

5

6

1. Cap screw

2. Entry hole types

3. Standard nut and SAE washer

4. Whiz nut or spiralock: up to 1/2 in. dia. hardware

5. Weld nuts: above 1/2 in. dia. hardware

6. Exit hole types

Figure 2 Acceptable Hardware Combinations

Loading...

Loading...