20-102 PC09-1

TESTING AND ADJUSTING

MEASUREMENT OF ENGINE

ROTATION

★ Engine rotation measuring tool

When installing or removing the measuring

instrument, be careful not to touch a highly

heated portion of the engine.

★ Carry out measuring the engine rotation under

the following conditions.

• Engine cooling water temperature: To be

within the operating range

• Hydraulic oil temperature: To be between 45

– 55°C

1. Open up the engine hood.

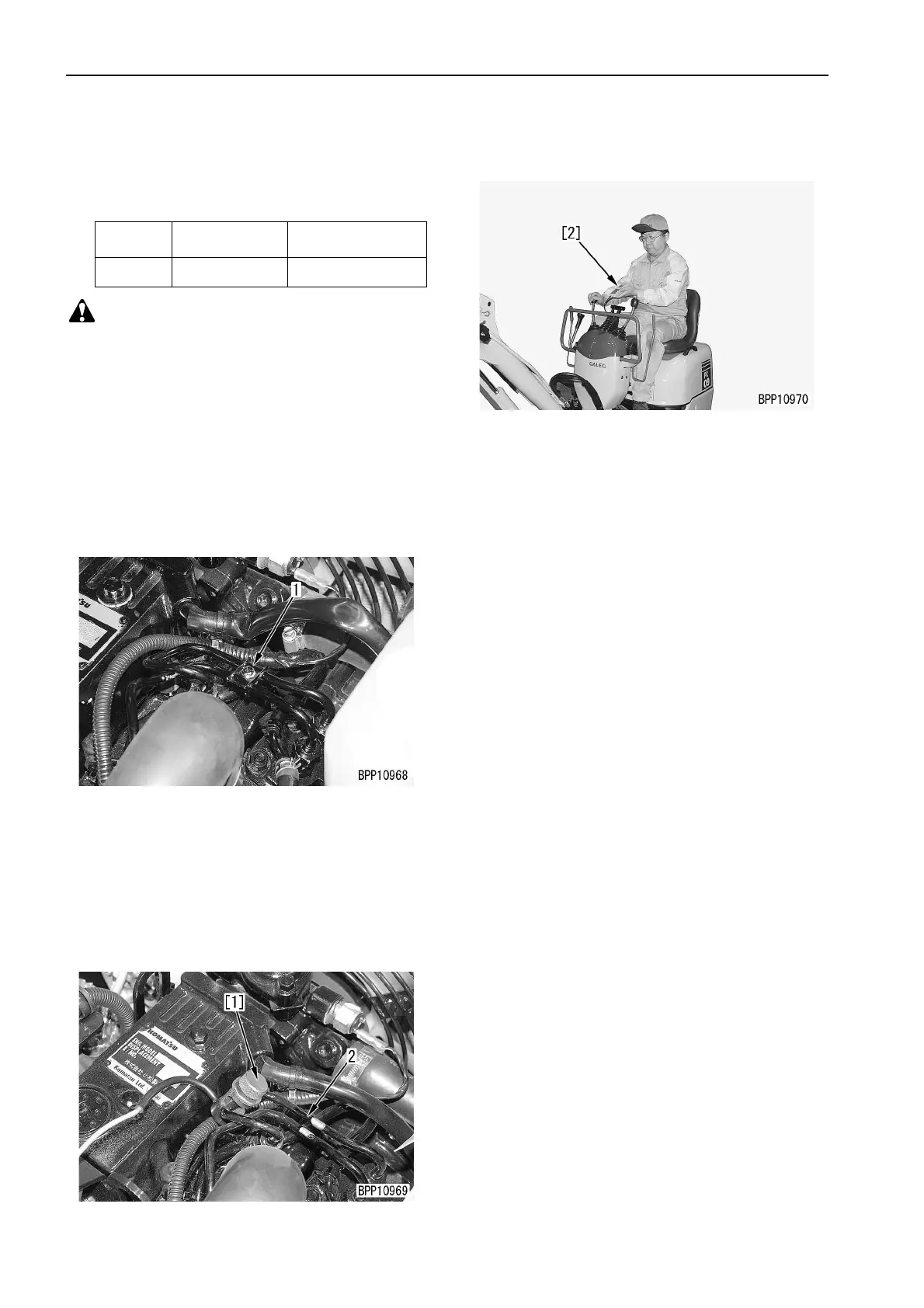

2. Remove clamp (1) of the fuel injection piping.

.

3. Install clamp [1] of multi-tachometer A to fuel

injection piping (2).

★ With 2D68E engines, the No. 1 cylinder is

located on the flywheel side. The clamp may be

installed to either of the No. 1 and No.2 cylin-

ders.

Symbol Part No. Part Name

A 799-203-9000 Multi-tachometer

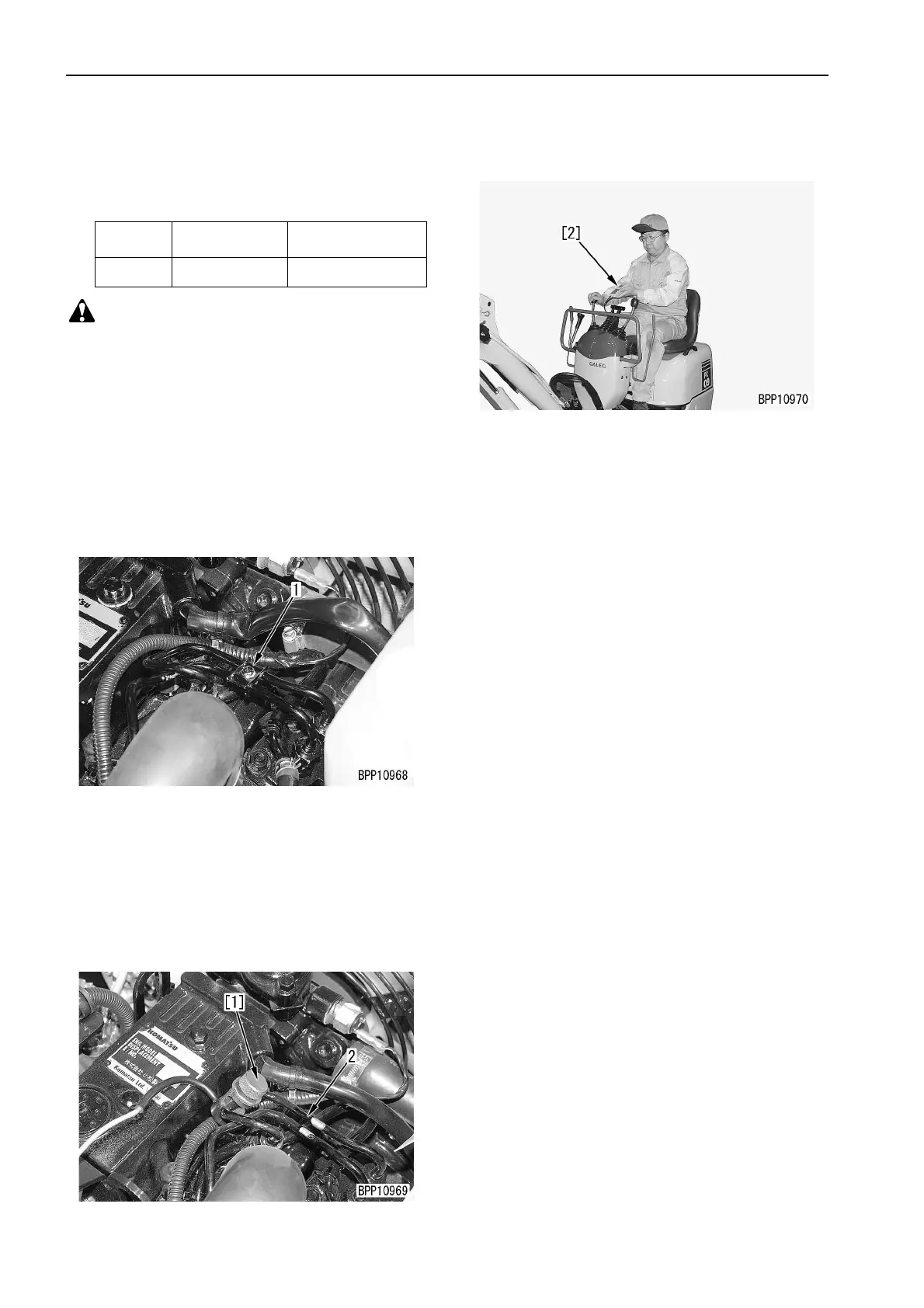

4. Connect clamp [1] to an amplifier and meter [2].

★ Adjust amplifier sensitivity so that a steady

engine rotation may be read out.

5. Start the engine and measure each engine rota-

tion under the following different conditions.

1) ROTATION at low idling

Set the fuel dial to the low idling position and

put all the control levers and pedals to the

neutral position, then measure the rotation.

2) ROTATION at high idling

Set the fuel dial to the high idling position

and put all the control levers and pedals to

the neutral position, then measure the rota-

tion.

3) ROTATION with 1 pump in relief state

Set the fuel dial to the high idling position

and put the arm cylinder in relief state at its

stroke end, then measure the rotation.

4) Rotation with 2 pumps in relief state

Set the fuel dial to the high idling position

and put both arm cylinder and bucket cylin-

der in relief state at their stroke ends simul-

taneously, and then measure the rotation.

MEASUREMENT OF ENGINE ROTATION

Loading...

Loading...