Crack in rubber shoe track

When a crack in a rubber shoe lug extends to approximately

60 mm, repair it.

NOTICE

If a crack occurs and the steel cords are seen, repair it im-

mediately, even if it is small and short.

A crack up to 30 mm long or 10 mm deep does not need to be

repaired.

For judgment of replacement, repair, and continuation of use of the rubber shoe track, consult your Komatsu

distributor.

METHOD FOR CHECKING AND ADJUSTING RUBBER SHOES TRACK TENSION

(Rubber shoe specification)

• Wear of the rubber shoe depends on the working condition and type of soil. Accordingly, check the wear

and track tension at appropriate intervals. For performing the inspection and adjustment of the track shoes,

park the machine on the level and firm ground.

• When the machine is new or a new part is installed, the track becomes loose for 5 to 30 hours after the

tension is set to the specified value while the machine travels repeatedly. If you adjust the track tension at

short intervals until the initial loosening is finished, “coming off of the track caused by insufficient track ten-

sion” is prevented.

• Working with the track loosened can cause coming off of the track and rapid wear of the core metal.

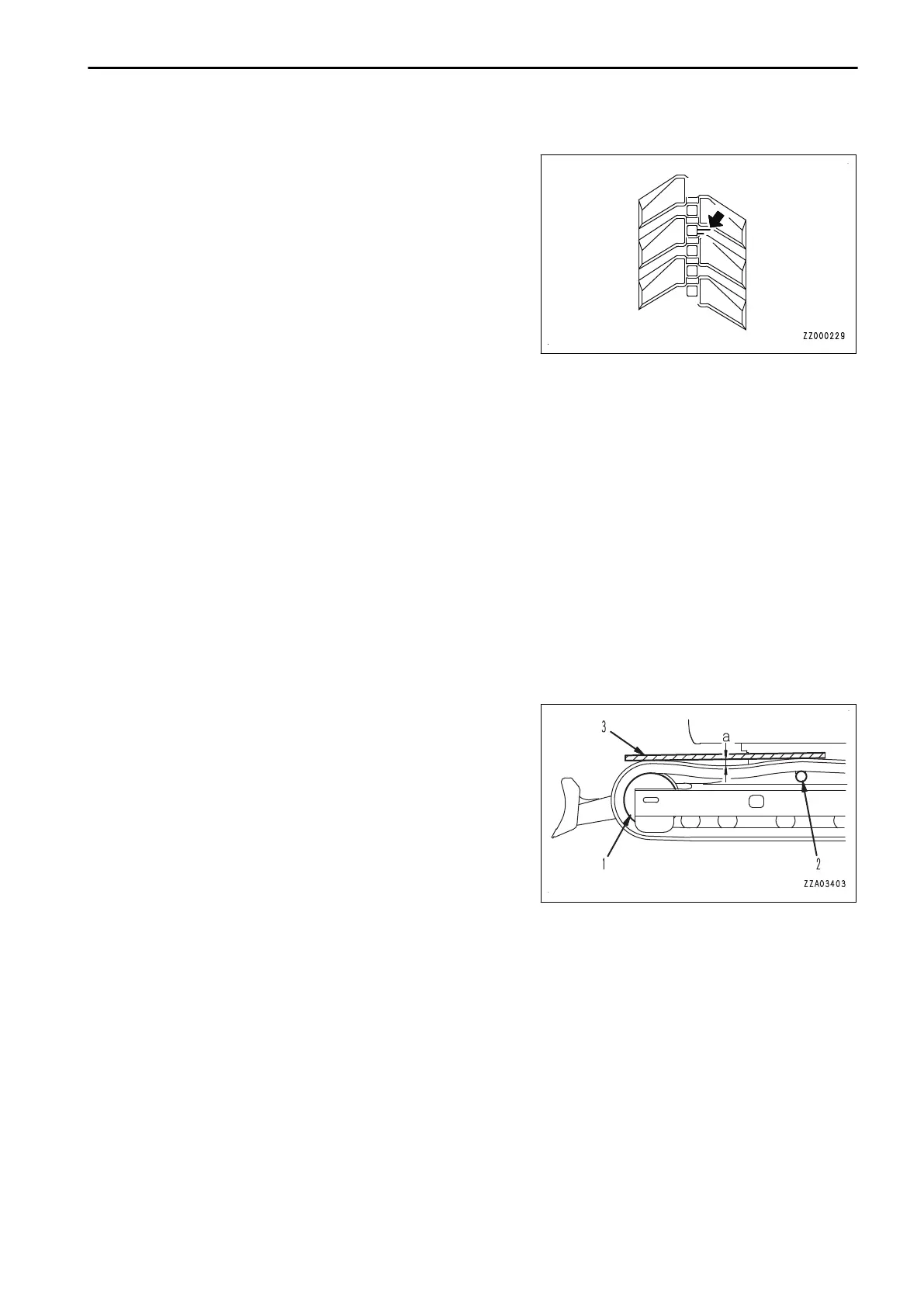

METHOD FOR CHECKING RUBBER SHOES TRACK TENSION

1.

Run the engine at low idle, then move the machine forward for a distance equal to the track length on

ground, and slowly stop the machine.

2.

Place straight wooden square bar (3) which reaches from

idler (1) to carrier roller (2) on the track.

3.

Measure maximum deflection (a) between the under sur-

face of the wooden bar and top surface of the track.

Standard deflection:

Deflection (a) should be 1 to 3 mm.

If the deflection is out of the standard range, adjust it into the standard range.

METHOD FOR INCREASING RUBBER SHOES TRACK TENSION

NOTICE

Since the standard value is small, take extreme care not to tense the rubber shoe track too much.

Prepare a grease pump.

MAINTENANCE MAINTENANCE PROCEDURE

4-27

Loading...

Loading...