EN

UAB KOMFOVENT we reserve the right to make changes without prior notice

C5.1_22- 08

18

2.8. Troubleshooting

If the unit fails to operate:

• Make sure that the unit is connected to the power supply network.

• Check whether the main switch (if designed) is turned on.

• Check all fuses of the automatics. If necessary, replace blown-out fuses with new ones having the

same electrical parameters (the sizes of the fuses are indicated on the schematic electrical diagram).

• Check whether there is any failure message on the control panel. If there is indication, it needs to be

eliminated rst. In order to eliminate the failure, follow the table.

• If nothing is indicated on the control panel, check whether cable connecting control panel with the

unit is not damaged.

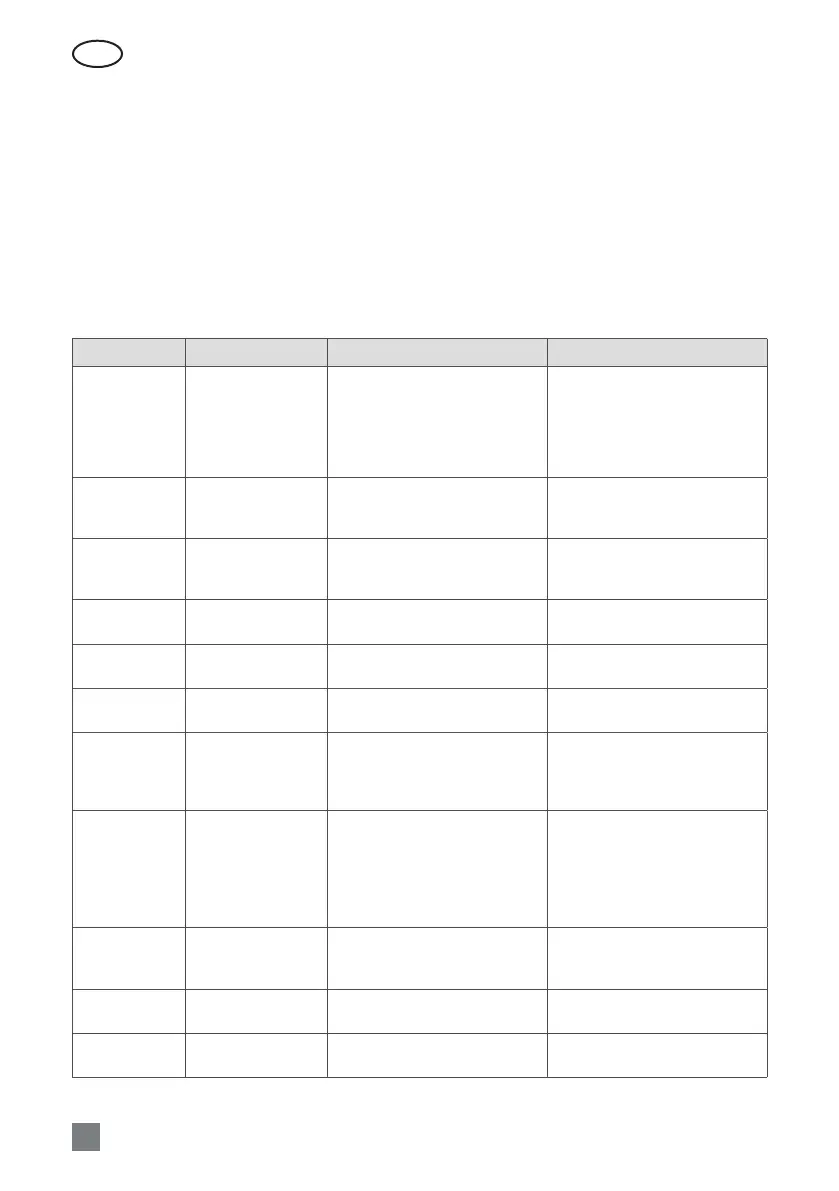

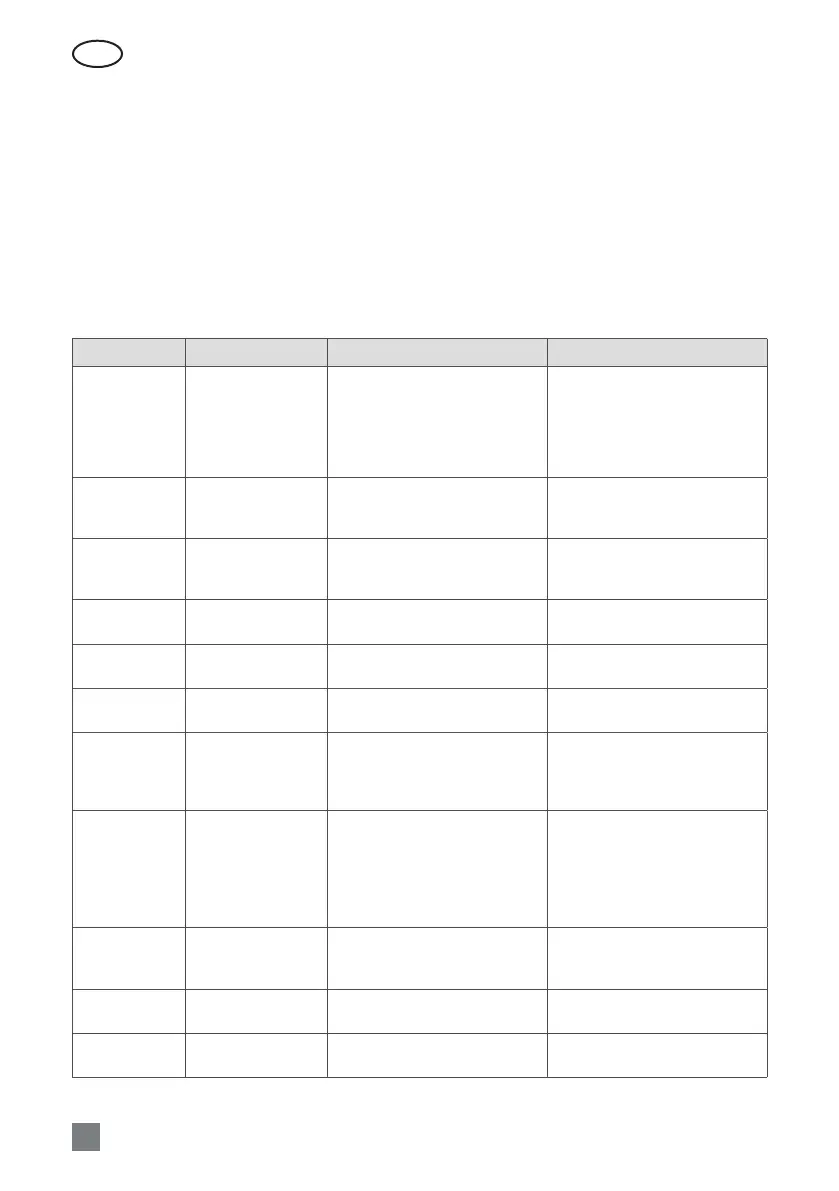

2.8 Table. Alarms indicated on the control panel, their possible causes and elimination methods

Code Message Possible cause Elimination

14B Service time

If unit continuous operation

(without breaks) was 12 months,

then periodic inspection message

appears.

After disconnecting the unit from

power supply, it is necessary to

carry out periodic inspection of

the unit, i.e. to check the condition

of the heat exchanger, the heater

and fans.

1B, 19A Low supply air ow

Too high resistance of the ventila-

tion system.

Check pressure pipes, air dampers,

air lters and make sure that the

ventilation system is not blocked.

2B, 20A Low extract air ow

Too high resistance of the ventila-

tion system.

Check pressure pipes, air dampers,

air lters and make sure that the

ventilation system is not blocked.

3B VAV calibration fail

Pressure sensors are not con-

nected or broken.

Check connections of the sensor or

replace the sensor.

4B

Change outdoor air

lter

The fresh air lter is blocked.

Shut down the unit and replace

the lter.

5B

Change extract air

lter

The extract air lter is blocked.

Shut down the unit and replace

the lter.

6B -11B Electric heater o

The heater is disconnected due to

too low air volume.

As soon as the heater cools down,

protection resets automatically. It

is recommended to increase the

ventilation intensity level.

113B,114B

CF exchanger not

calibrated

CF exchanger calibration not

performed or failed

Make sure that all doors are

closed, there is no obstruc-

tions in the ducts and AHU can

reached airflow setpoint of COM-

FORT 1 mode. Repeat calibration

manually (see2.5.1.3.).

127B Service mode

Temporary mode, which can be

activated by the service personnel.

The service mode is switched

o by simply deleting the alert

message.

1A, 2A

Supply air tempera-

ture sensor failure

The supply air temperature sensor

is not connected or broken.

Check connections of the sensor or

replace the sensor.

3A, 4A

Extract air tempera-

ture sensor failure

The discharged air temperature

sensor is not connected or broken.

Check connections of the sensor or

replace the sensor.

Loading...

Loading...