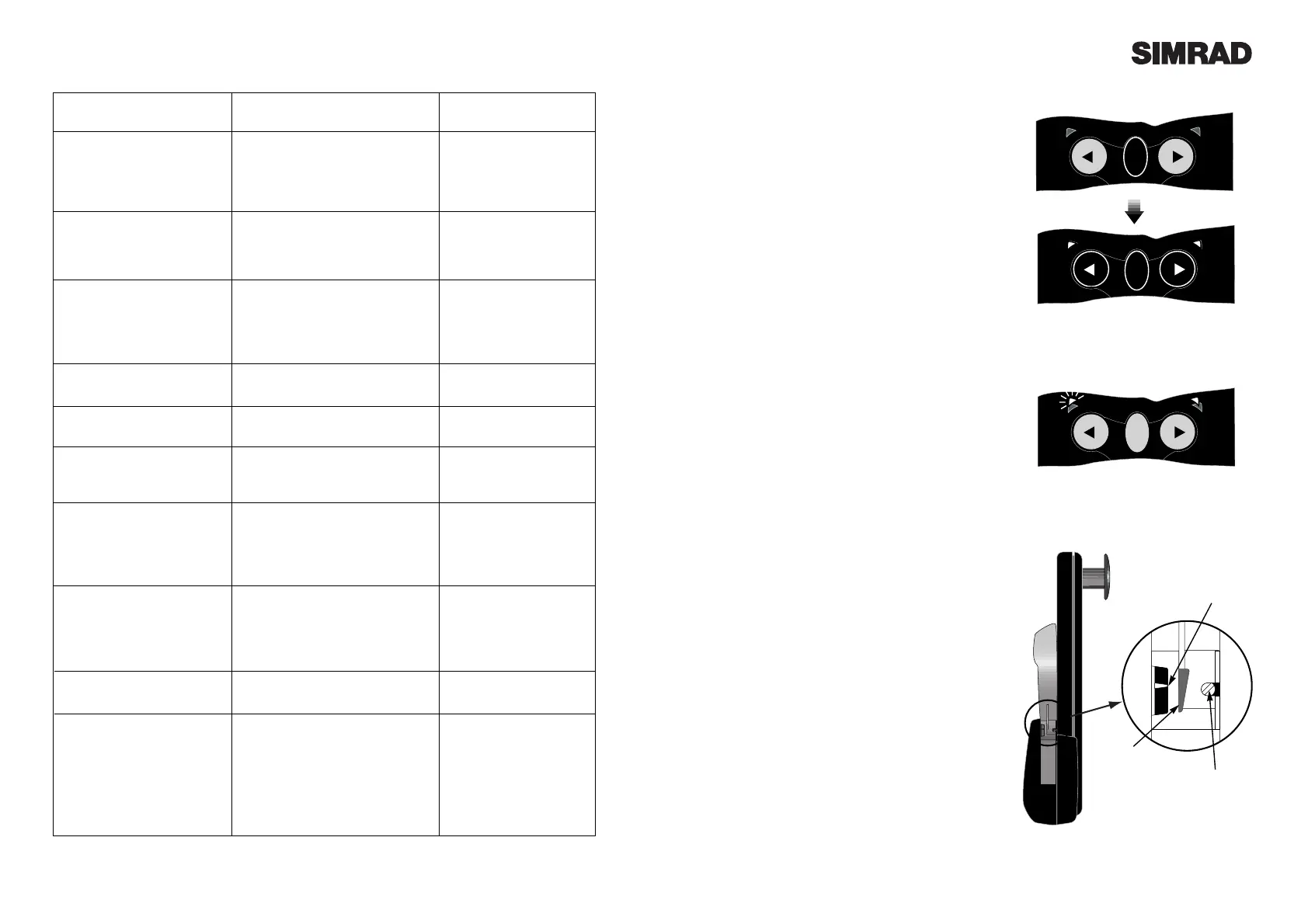

Symptom

Pilot consistently over or

under compensates when a

course error is detected

After functioning normally

course is suddenly lost and the

Wheelpilot goes into Standby

Mode.

Helm is hard over and alarm is

continuously on.

Power supply is live, but pilot

is not on.

Loss of course under Sail To

Wind Mode.

Cannot select Sail To Wind

Mode.

Cannot select NavLock Mode.

Autotack function not

working.

Pilot exits NavLock before

waypoint is reached.

Pilot does not hold accurate

course in auto mode

Probable Cause

* Gain setting is respectively too high

or too low.

* Steering sensitivity scaling has been

incorrectly set

* Power interrupted briefly, or low

voltage.

* Supply cable used too small.

* Intermittent connection.

* Steerage way insufficient to control

course, or sails are aback.

* Steering scaling set too high

* Wheelpilot is wired incorrectly.

* Apparent wind has become too light

to give a consistent direction.

* Masthead unit is not connected.

* Required NMEA sentence not being

transmitted.

* Navigational receiver not connected.

* No waypoints have been

programmed.

* Wrong NMEA format is being used.

* Pilot is in NavLock Mode.

* Pilot is in Steer To Wind Mode and

a) apparent wind is >90¼

b) autotack being attempted is in

the wrong direction.

* Cross Track Error has exceeded 1.21

Nm.

* Fluxgate compass is being affected

by interference from nearby magnetic

influences (binnacle compass,

speakers) or metallic objects (winches,

deck hardware etc).

Remedy

* Adjust gain setting (see

section 4.3).

* Enter the correct scaling for

the vessel (see section 4.1).

* Increase size of cable.

* Check all connections.

* Charge batteries.

* Uprate batteries.

* Reset the vessel on course

and re-engage pilot

* Enter the correct scaling for

the vessel (see section 4.1).

* Check wiring of pilot

(see section 5.2).

* Change to Compass

Mode.

* See section 5.5.

* Check NMEA interface

connections.

* Check NMEA0183 format

is being transmitted by

navigational receiver.

* Exit NavLock.

* Luff up until apparent

wind is less than 90¼.

* Reset the vessel on course

and re-engage NavLock.

* Check compass has been

calibrated (see section 5.3).

* Fit ATC600 external

fluxgate compass instead.

* Replace binnacle compass

with bulkhead compass.

* Relocate objects that are

causing interference.

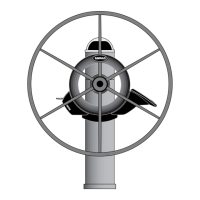

6.3 Auto Compass Calibration

Although the Wheelpilot internal compass is extremely

accurate, after installation it is necessary to calibrate the

compass to compensate for any deviations caused by

objects surrounding it on board the vessel.

With the vessel motoring along slowly (2-3 knots) in

calm conditions and the Wheelpilot in Standby Mode,

press the Starboard key a number of times to induce a

slow clockwise rotation of the vessel. Press and hold the

TAC K key, followed by the Por t and Starboard keys

simultaneously to enter Auto Compass Calibration

Mode (Fig 6.1). The Port and Starboard LEDs will both

light. Allow the vessel to turn through a minimum of

1

1

/

4

turns (450¼) in approximately two minutes, during

which time the fluxgate compass will automatically cali-

brate itself.

If the rate of turn or the boat speed is too high, the Port

LED will flash (FIg 6.2) indicating that it is necessary to

either slow the boat or decrease the angle of turn. If the

rate or turn or boat speed is too slow the Starboard LED

will flash, indicating that it is necessary to either

increase the boat speed or increase the angle of turn. A

double beep will indicate that the calibration has been

successful, and the Wheelpilot will return to Standby

Mode. If the calibration has been unsuccessful after a

period of four minutes, a long beep will sound. Try

again carefully following the above directions.

Note that this function is only available for auto cali-

brating the internal fluxgate compass. If an ATC600

external compass is being used, this is calibrated using a

separate display head. Please contact Simrad Product

Support for more information.

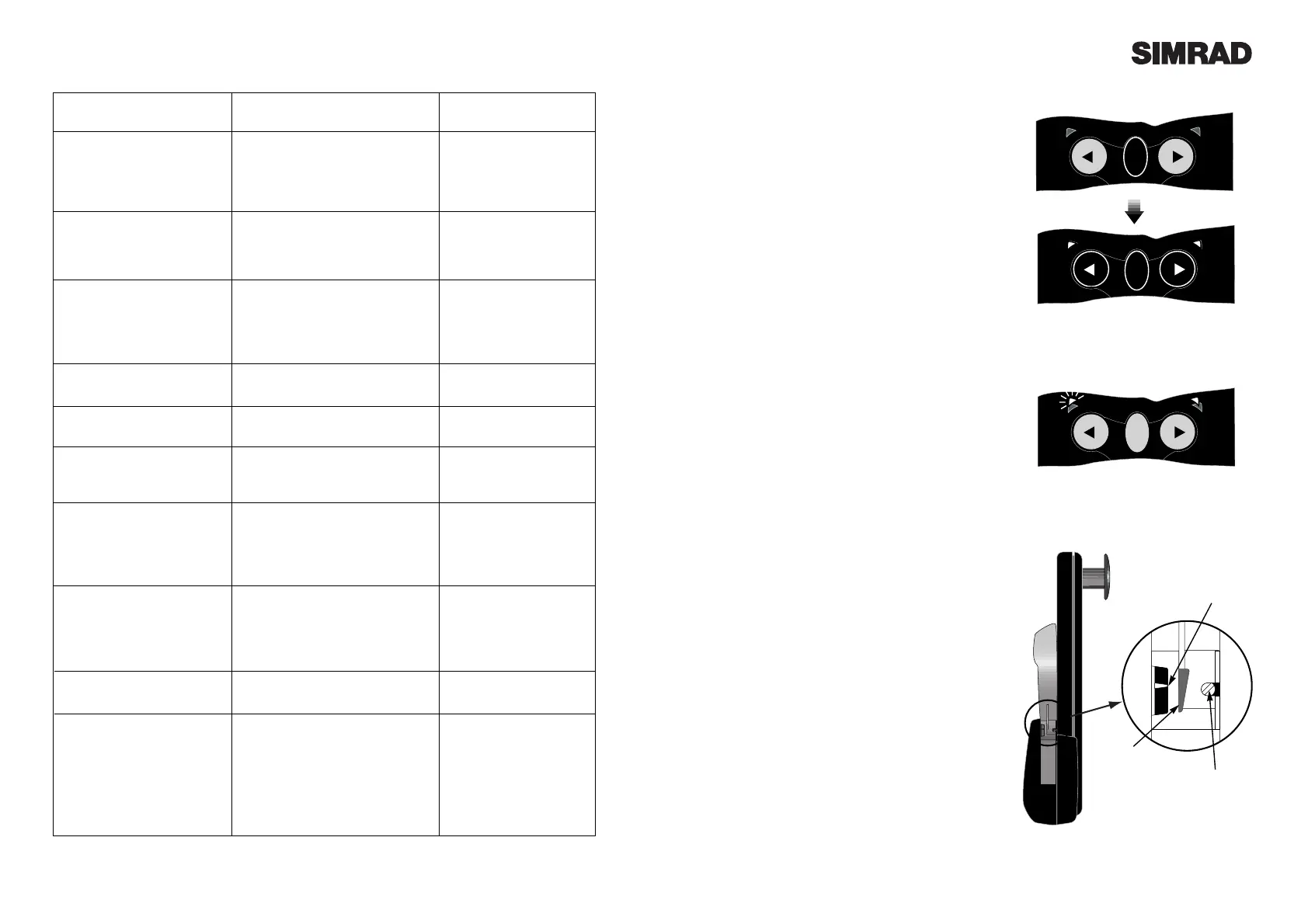

6.4 Adjusting Belt Tension

The belt tension is set when the Wheelpilot is assem-

bled, however it may be necessary to adjust this during

the lifetime of the pilot.

The tension is adjusted by means of a screw situated

underneath the clutch lever. This screw is only accessi-

ble when the lever is in the up (disengaged) position. To

increase the clutch tension, turn the screw clockwise. To

decrease the tension, turn the screw anticlockwise. The

scale next to the screw indicates the current tension set-

ting. When the pointer is at the top, the clutch is at max-

imum tension. Minimum tension is indicated when the

pointer is at the bottom.

Loading...

Loading...