Rev. Date: 3/14/18 Page 15

MODEL #500

Mechanical Settings (cont.)

OPTIONAL SHREDDER ASSEMBLY:

If this unit is supplied with a shredder assembly; airlock/agitator speeds are preset at the factory. No further sprocket setting

speeds are needed, as this system will accommodate most fibers and applications. However, the shredder direction can be

adjusted as described below.

SHREDDER ADJUSTMENT:

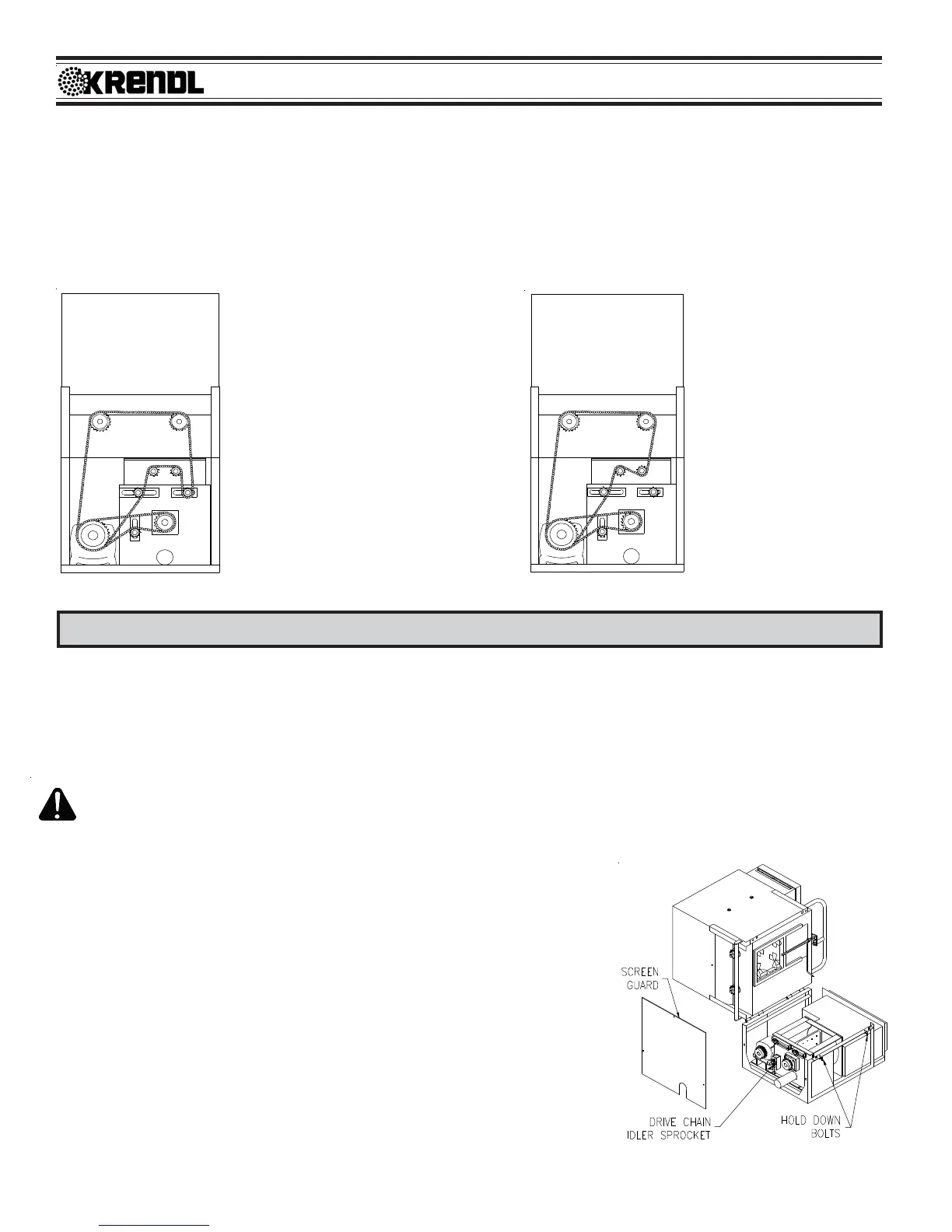

(illustration K) (illustration L)

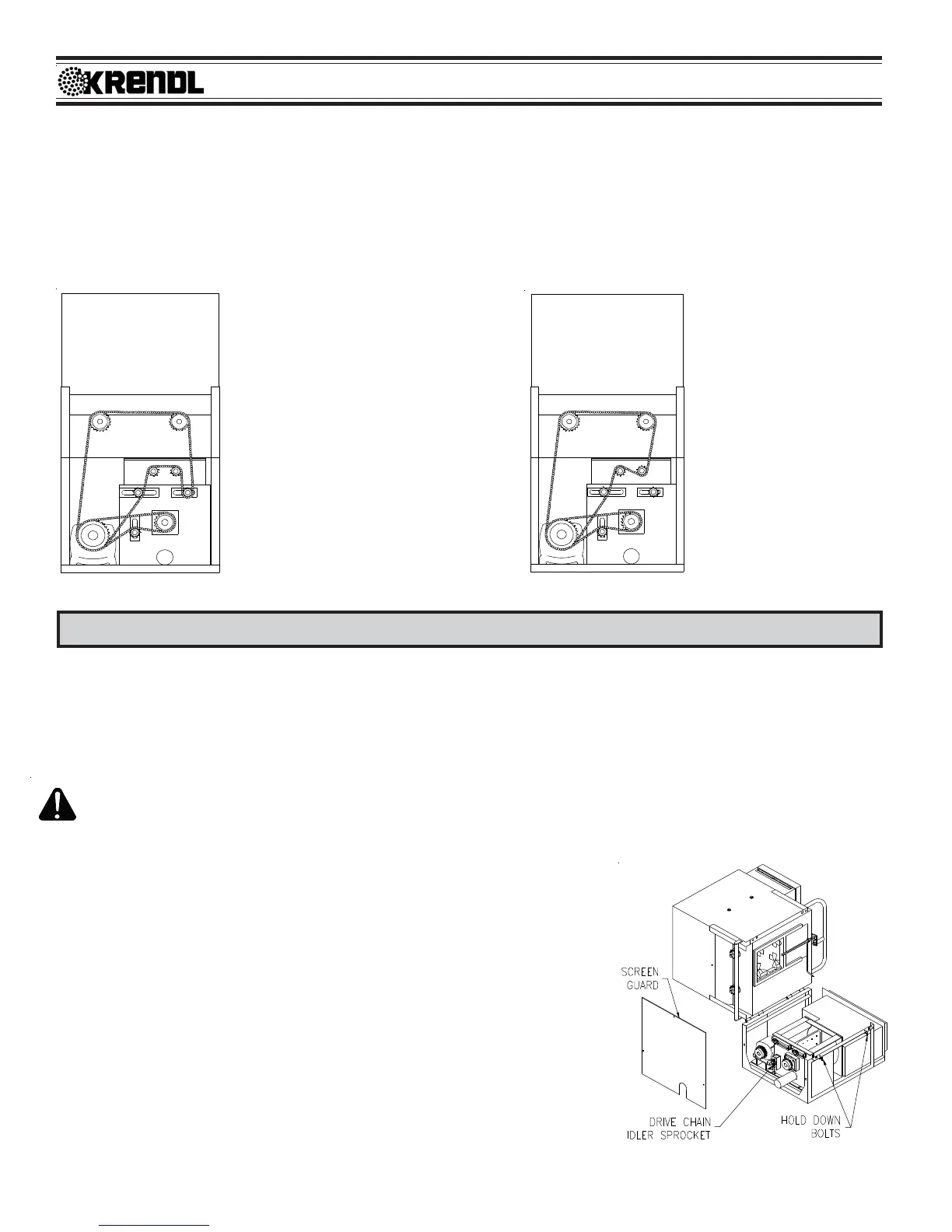

GENERAL MAINTENANCE

Periodic preventive maintenance will add years of life to your equipment. Reviewing the information in this manual will go a

long way in reducing downtime and lost income. To Flip hopper up for easy maintenance of lower base unit: (See illustration

M) Remove side screen guard of machine. Loosen idler sprocket and remove drive chain. Release hold down bolts at airlock

end of machine and lift hopper back gently until it rests safely on the floor.

KEEP CLEAN: During operation, keep material from accumulating on Blower Filter. Always keep Filter in place while

operating machine. After each use, remove fiber from hopper and blow out hose. (Use BLOWER mode at Main Control

Panel or Hand Pendant.) Clean air from insulation hose can then be used to blow fiber from agitator motor and Blower

Filter area. The Blower Door attached to this unit reduces filter maintenance.

Unidirectional Rotation (See il-

lustration K) is preferred as an

all-around setting for a combina-

tion of materials and applications.

This setting provides for the great-

est coverage and best control

of the fibers in wall cavity spray,

commercial spray, internal wet-

ting (stabilized) and open blow

applications.

Center-Down Rotation

(See illustration L) force

feeds the fiber into the

airlock at a faster rate.

This direction is preferred

for the greatest produc-

tion of various fibers in an

open attic blow application

although coverage may de-

crease.

AIRLOCK:

SEAL REPLACEMENT: The purpose of the airlock seal is to trap air and fiber until

it rotates 180

O

to the 6:00 o'clock position. At this point, fiber is pushed by air from

the blower, out of the chamber. Worn or damaged seals allow air and fiber to

escape back into hopper, thus reducing production and coverage. When it is

necessary to replace seals, follow these directions:

Airlock rotor plates that are damaged (bent) will need replaced. (Refer to Rotor

Plate Replacement on next page.) Take out rubber seal by removing six plate

fastening bolts and top plate. The base plate will remain attached to airlock shaft.

To install a new seal, reverse procedure. Seal should be inserted tight against the

back base plate, pressing the lower tabs of seal down under the adjacent seal with

a flat blade screwdriver. (See illustration N-1) Make sure all bolt holes are aligned

while each side of seal is equally pressed against the end plates, before tightening

bolts. Seal should be bent backwards for counterclockwise rotation, viewing from

drive side of machine.

(illustration M)

Loading...

Loading...