Functional description

12/18 810.00113.0

5.2.3 "INT280-xxx" Diagnose

By means of the diagnose port, data such as the last 20 errors, error counters, current status and switching

behaviours can be read out with the INTspector.

A variety of parameters to be adjusted for optimal adaption to the application. Refer to the data sheet on which

parameters these are.

5.3 Explanation of individual parameters

Parameter name

Filling cycle type With "fixed", the filling cycle runs with the set filling and break time. If the filling

cycle type is switched to "adaptive", the "INT280-xxx" calculates the optimal

filling and break times itself. The times are calculated so that the set nominal

filling period number is calculated.

Filling time Time that the solenoid valve is opened cyclically if there is an oil deficiency.

Break time Time that the solenoid valve is closed cyclically if there is an oil deficiency. The

time is specified in percent of the filling time.

Overfill time Once the fill level of the oil has been reached, the solenoid valve remains open

for the time set here.

Set number of filling periods With "adaptive" control, the oil level regulator calculates the times so that this

number of filling times is needed until the filling.

Oil deficiency alarm monitoring A choice can be made here whether the alarm delay of the compressor run

should be evaluated or not.

Oil deficiency alarm delay If a deficiency of oil is detected, this time is started. Once the time has elapsed,

the relay switched the compressor off. If the function "Alarm monitoring only

when compressor is running" is active, the time is stopped when the

compressor is at standstill. Once the compressor starts up again, it continues

to run.

External alarm via DP bus When the Diagnose devices are connected, a choice can be made here whether

an alarm from a different Diagnose device will also cause the alarm relay of the

oil level regulator to be switched off and that the alarm is displayed at the LED

of the oil level regulator.

Operating recognition via DP bus A setting can be made here whether the run detection should be evaluated or

not of a connected Diagnose compressor protection unit.

Behaviour monitoring A setting can be made here whether the behaviour monitoring should be active

or not.

Filling cycle time overrun coefficientWhen the DP bus run detection is active, the oil level regulator determines an

average filling cycle time. If this time is exceeded during a filling process for the

coefficient set here, a warning is generated.

Time overrun without filling

coefficient

When the DP bus run detection is active, the oil level regulator determines an

average time without filling process. If this time is exceeded during compressor

run for the coefficient set here, a warning is generated.

Soiling stage 2 The glass cone is monitored for soiling. A choice can be made here whether the

compressor should be switched off if the second soiling stage is exceeded.

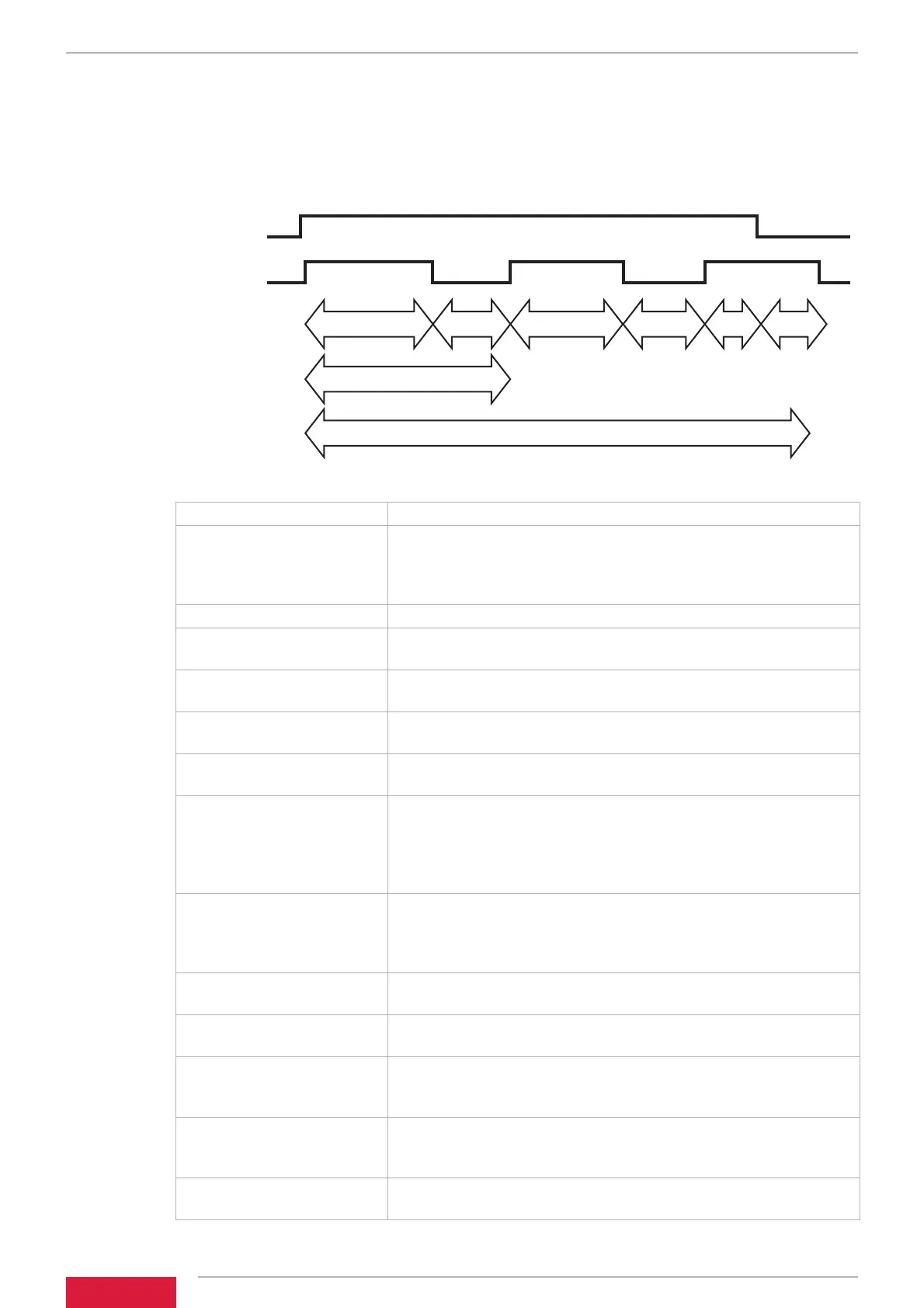

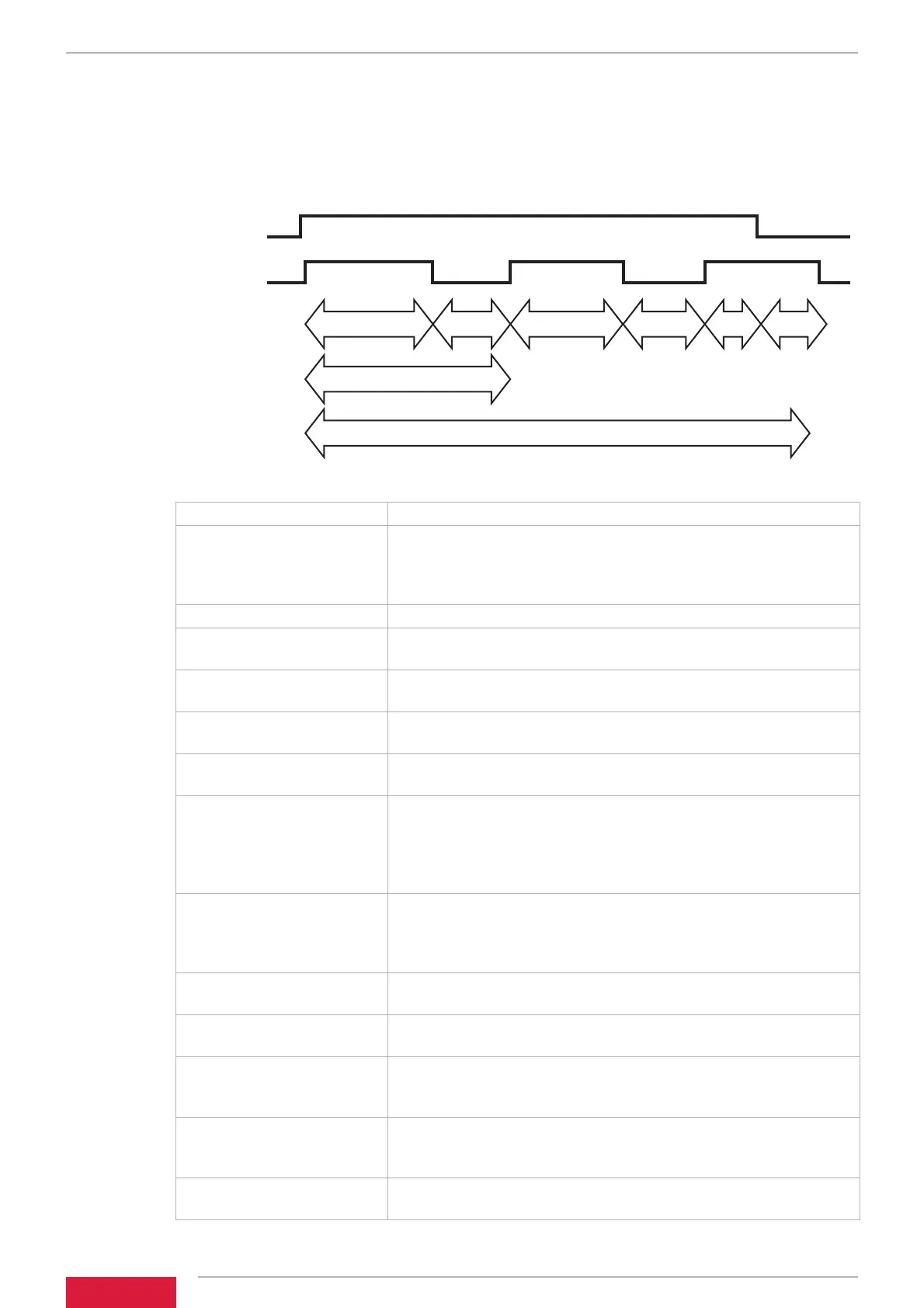

too low

good

open

closed

Oil level

Solenoid valve

Filling time Break time Filling time

Filling

Break time

Overfill

Filling period

Filling cycle

time

time

Loading...

Loading...