GB-7

Manual calibration

▷ The minimum and maximum opening angle can

be anywhere within the range set using switching

cams S3 andS4.

Move the valve to the required min. position by

pressing toggle switchS11.

Press the min button (approx. 3seconds) until the

blue LED goes out briefly (approx. 0.5seconds).

Move the valve to the required max. position by

pressing toggle switchS11.

4 Press the max button (approx. 3seconds) until

the blue LED goes out briefly (approx. 0.5sec-

onds).

Characteristic curve inversion

▷ The mA value for low fire has to be greater than

the mA value for high fire.

Press the min or max button until the red LED

lights up briefly (approx. 0.5 seconds) and hold

it in for approx. 3 seconds more until the blue

LED goes out briefly (approx. 0.5 seconds).

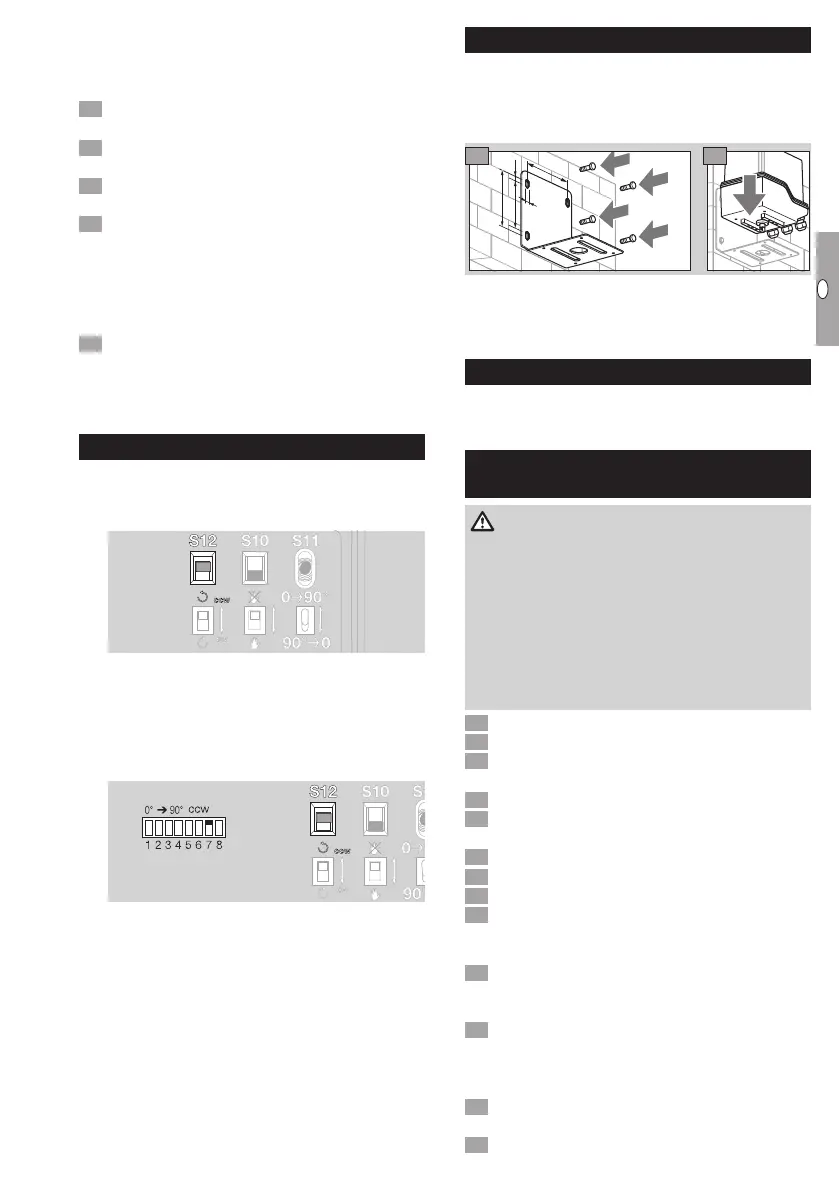

Changing the direction of rotation

IC 50

▷

The direction of rotation is defined using slide

switchS12.

▷

cw (blue mark on the cover) = valve opens

clockwise,

ccw (white mark) = valve opens anti-clockwise.

IC 50..E

▷

The direction of rotation is defined using DIP

switch7 and slide switchS12.

IC 50, IC 50..E

▷ When changing the direction of rotation, these

two switches must be set to the same position:

cw (blue mark on the cover) and ccw (whitemark).

▷

The function of switching cams S3/S4 changes

if the direction of rotation (ccw/cw) is modified,

see page6 (Commissioning).

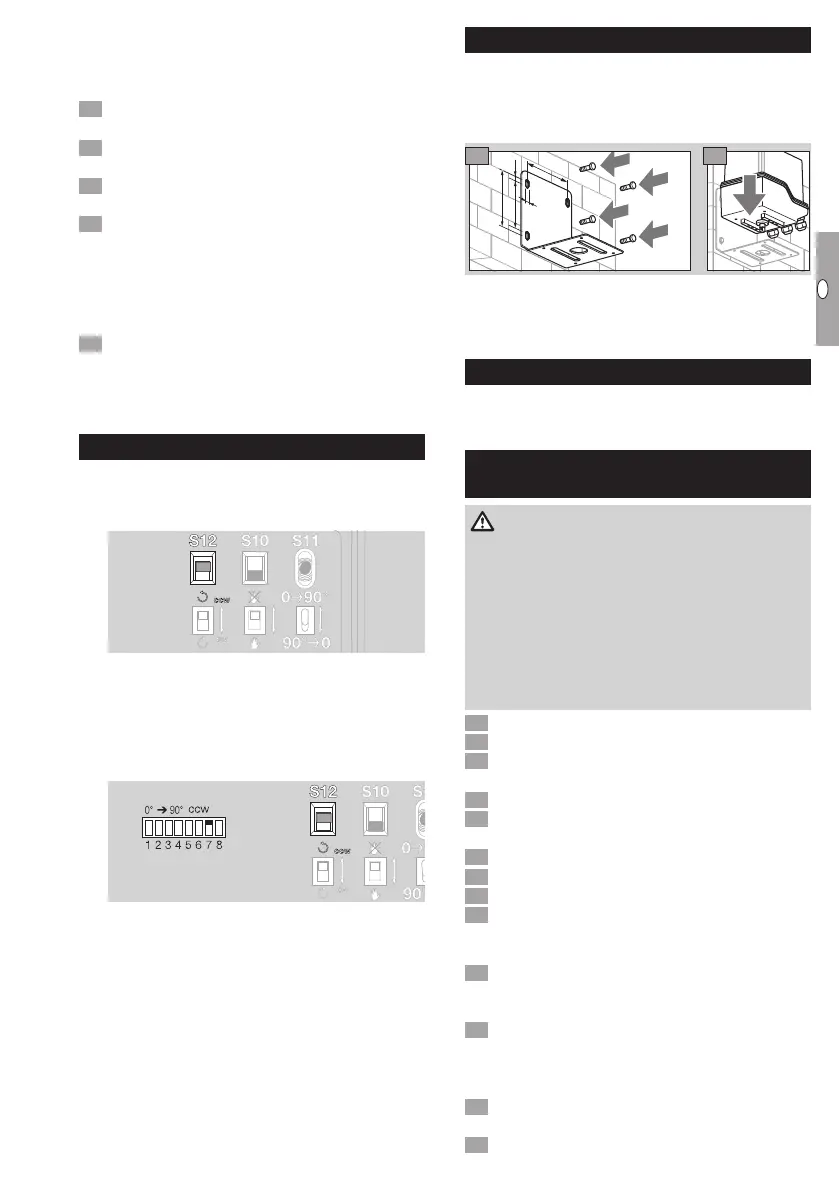

Accessories

Wall mounting bracket

The wall mounting bracket is required if the actuator

is to be attached to a wall.

OrderNo.: 74924791

10

93

113

7

1 2

▷

Attachment sets for mounting to butterfly

valveDKR, see Butterfly valve DKR operating

instructions.

Maintenance

Actuators IC 50 suffer little wear and require little ser-

vicing. We recommend a function check once a year.

Assistance in the event of

malfunction

WARNING

To avoid harm to persons and damage to the unit,

please observe the following:

– Electric shocks can be fatal! Before working

on possible live components, ensure the unit

is disconnected from the power supply.

– Never remove the circuit board!

– Unauthorized repairs or incorrect electrical con-

nections may cause the butterfly valve to open

resulting in defects.

? Fault

! Cause

• Remedy

? The valve disc does not move.

! The actuator is in Manual mode (IC50..E: blue

LED is lit).

• Set slide switch S10 to Automatic mode.

! No voltage at terminal 5.

• Check voltage at terminal 5.

! Motor coil or electronics defective as a result of

excessive ambient temperature and/or excessive

operating voltage.

• Check ambient temperature and/or operating

voltage, see type label or page8 (Technical

data).

! Cam trip points maladjusted. S4 has been set to

a wider angle than S3 (IC50..E: red LED lights

up, blue LED flashes 1×, if the unit has been

automatically calibrated).

• Adjust the trip points, see page6 (Commis-

sioning). Then calibrate the IC50..E.

! Electrical fault!

Loading...

Loading...