18

Fan Powered Terminal Units IOM

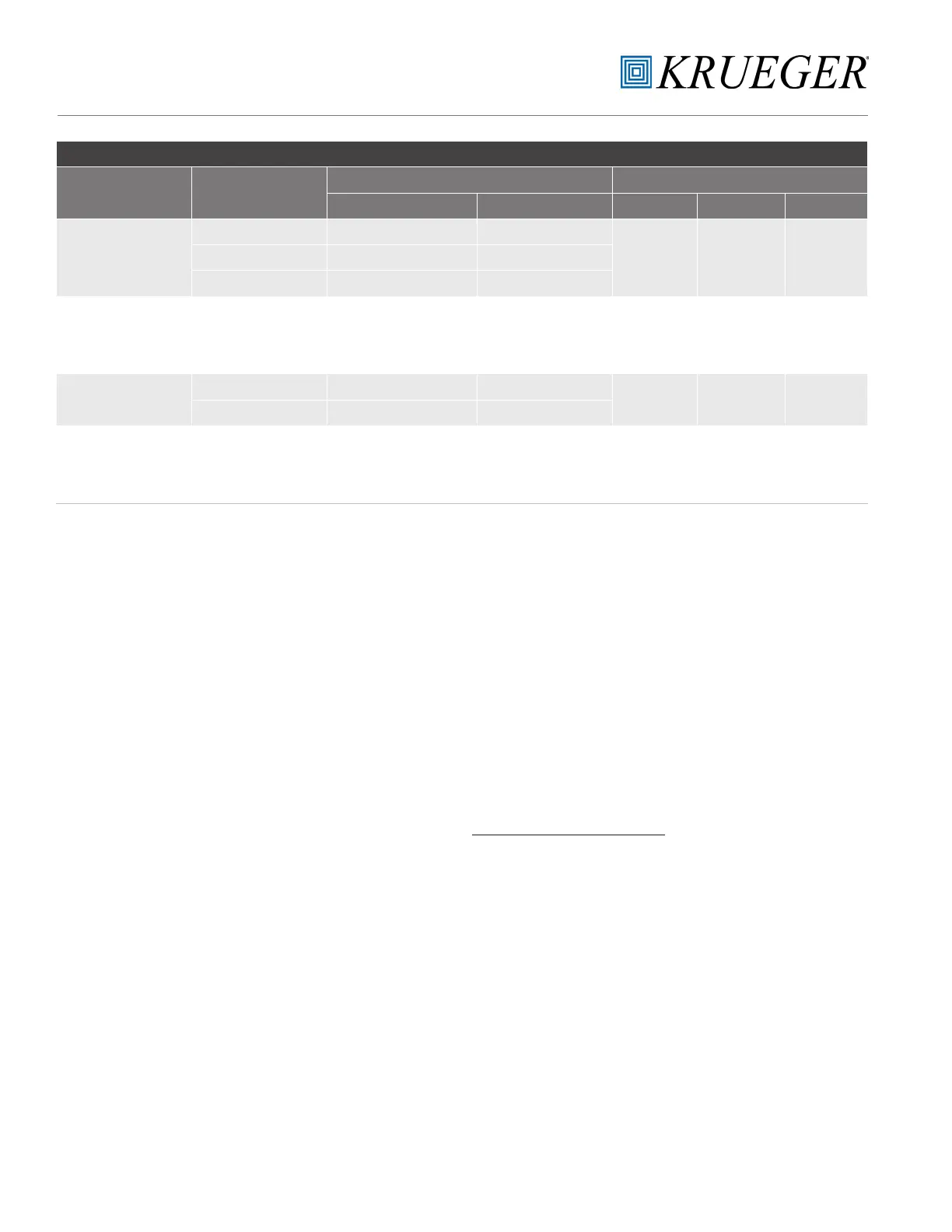

TABLE 10A – KLPS-D Series Fan Terminal Unit

UNIT SIZE INLET SIZE

PRIMARY AIR FLOW ECM MOTOR

MAX MIN MOTOR HP MAX FAN MIN FAN

1

4 230 40

1/3 775 1055 350 62

6 515 90

2

4 230 40

1/3 875 1355 350 62

6 515 90

3

6 515 90

1/3 1000 150

8 920 160

5

6 515 90

1/2 11625 2508 920 160

10 1430 250

Note: Minimum Primary airow may be 0 cfm.

BALANCING PARALLEL FLOW UNITS

The KLPP, KQFP, and QFV parallel fan terminals are designed

to operate with the fan supplying air equal to 40 to 60% of

the VAV damper maximum primary air setting. Adjustments

to the parallel units fan should be made with the primary

air closed o. Refer to unit capacity tables to ensure

airow through the electric heater meets the minimum

requirements before operating heater.

Each control option has specic procedures required for

balancing the unit, but some steps are common to all parallel

fan units, as described below.

To balance parallel fan unit:

SETTING FAN AIRFLOW

NOTE: If the unit has electric heat or hot water heat,

temporarily disable these functions before balancing

the fan.

If unit has optional electric heat disconnect downstream of

fan motor connections to power, open disconnect. If unit

does not have optional electric heat disconnect, re-move

one electric heat power line connection. Be sure to insulate

loose line from ground wire or other wires.

1. Set the controller to provide heating airow demand only.

Typically, this is accomplished by setting the thermostat

to the highest possible temperature setting.

NOTE: A minimum of 0.1” w.g. downstream static

pressure is required in the duct to ensure proper

heater operation.

2. Determine that the VAV damper is fully closed. This may

require a temporary override of the VAV controller. Do

not adjust minimum and maximum cfm set points at this

time.

3. Using a ow hood or duct traverse, determine the

delivered fan airow (cfm).

NOTE: Both ow hood and duct traverse are subject

to measurement errors. Be sure that all applicable

measurement precautions are taken.

4. Compare the required design cfm in heating mode to the

actual delivered airow. If there is a minimum setting for

the VAV damper in heating mode (as recommended by

ASHRAE [American Society of Heating, Refrigeration, and

Air Conditioning Engineers] Standard 62), this quantity is

included in the total measured airow.

5. Adjust the fan SCR at unit control box to achieve the

desired airow rate.

SETTING OF VAV (PRIMARY) AIRFLOW

ADJUSTMENT OF SET POINTS

Each parallel fan unit is equipped with a pneumatic or

electronic volume controller that regulates the quantity of

cold primary air entering the terminal and the conditioned

space. If required airow levels are specied with the job

order, the minimum and maximum cfm levels will be set

at the factory. If minimum and maximum levels are not

specied, a default value is used. Other settings of minimum

and maximum primary airow must be set in the eld.

Airow (cfm) ranges for the primary air damper are shown

in Tables 11, 12 and 13 for KQFP, QFV and KLPP units. The

minimum primary airow (other than zero) is the minimum

ow rate controllable by the unit volume controller. The

primary air damper can be set at zero for shuto or at the

minimum cfm listed.

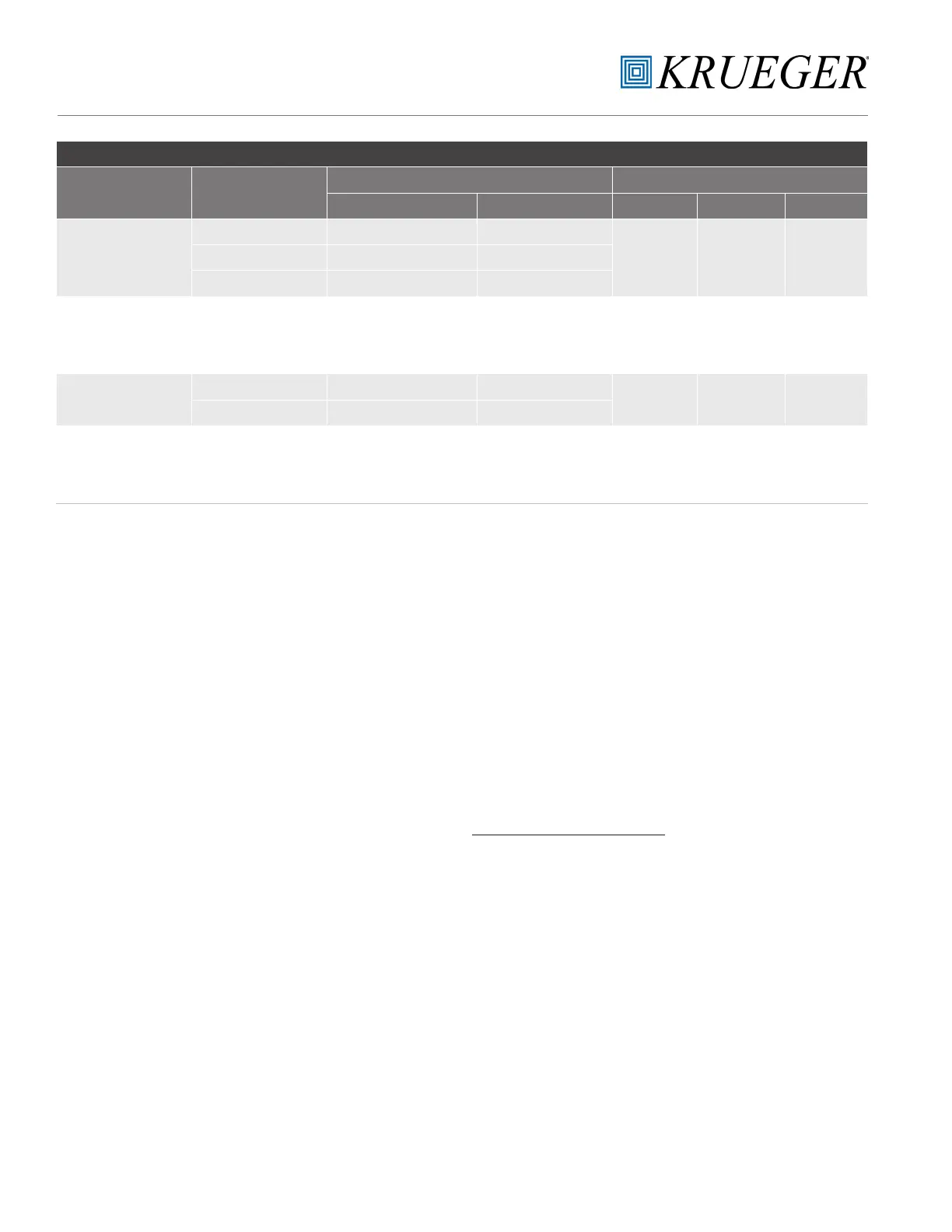

TABLE 10A – KLPS-D Series Fan Terminal Unit

Loading...

Loading...