Submersible Motor Pumps (150 mm and above)

1

1. General

KSB’s submersible Pump-motors, generally referred as

“pumpsets” in this manual are developed in accordance with

state- oftheart of design and manufacturing technology, with

extreme care and rigid quality control. This manual contains

important information for reliable operation of the pumpset.

The special feature of this submersible pumpset are installation

in narrow deep wells to pump the clean water for various

applications like water supply systems, irrigation & sprinkling

systems, ground water pumping, pressure boosting, fountains

etc.

For any additional information or instructions, please contact

KSB’s nearest office.

2. Safety of Pumpset

This operating manual contains fundamental installation,

operation and maintenance instructions. Hence this must be

clearly understood by concerned people, prior to the installation,

operation & maintenance. The booklet must always be located

for easy access at site.

2.1 Safety checks of Pumpset

• After the receipt of pumpset in a packed condition, check it

for any damages during transit and if observed, inform to the

concern KSB’s Dealer.

• Avoid lifting & dragging of motor through cable.

This operating manual does not take into account any safety

regulations those may apply specifically to the site. It’s a pump

operator’s responsibility that any such regulations are adhered

to.

2.2 Labeled instruction on pumpset

Follow the instructions given on the motor / pump e.g.

- Various plugs for water connections viz. filling, venting,

draining etc. on motor.

- Arrow indicating the direction of rotation.

2.3 Unauthorized spare parts and modifications

Modifications or alterations of the pumpset are strictly not

permitted. Original spare parts from KSB and accessories

authorized by the KSB only ensure safety of the pumpsets.

The use of spurious parts invalidates any warranty liability of

the manufacturer.

2.4 Unauthorized mode of operation

The warranty related to the operation reliability and safety of

the pumpset supplied is valid only if the equipment is operated

as per the designated parameters that have been mutually

agreed upon. The operating limits should not exceed from the

limits of Flow “Q” & Head “H” specified on the pump nameplate

and Voltage & Current in Amp specified on the motor nameplate.

2.5 Unauthorized site condition

The warranty of the pumpset will be in accordance with our

terms of Warranty Certificate. Our warranty will not apply if;

• The pump is used for handling the liquids other than those

specified / mutually agreed.

• The damages to the pumpset arise due to corrosion & erosion

or due to incorrect electrical supply connections or due to

reason not attributable to KSB.

2.6 Water characteristics

Submersible pumps are designed for handling the clean water,

within the following main characteristics: (As per IS 8034: 2002)

a) Turbidity : 50 ppm*, Max (Silica scale)

b) Chlorides : 500 ppm*, Max

c) Total Solids : 3000 ppm*, Max

d) pH value : 6.5 to 8.5

e) Temperature : 33

o

C, Max

f) Specific gravity : 1.004

g) Hardness : 300, Max (Drinking water)

* ppm - parts per million

3.0 Preparation for Installation

3.1 Installation and operational accessories

The following accessories are necessary for installation and

commissioning of the pumpset :

• Extended cable (to be calculated as per 3.3.3) with

vulcanizing Rubber compound / Cushion compound and

electric insulation PVC tapes.

• Control panels with protection devices, Discharge Valve,

Pressure Gauge, Discharge pipes.

• Overload Trip unit, Water Level Guard,

• 2 Pairs of supporting or installation clamps for vertical

installation (for Horizontal installation supporting arrangement

as shown in Fig. 7)

(The motor is supplied with 3 core waterproof cable in standard

length of 3.25 meter).

3.2 Auxiliary equipment required for installation

and dismantling

For installing and removing the pumpset, reliable lifting device

(e.g. crane, chain pulley block) is required to handle the total

weight of the pumpset, riser pipe and an extended cable weight.

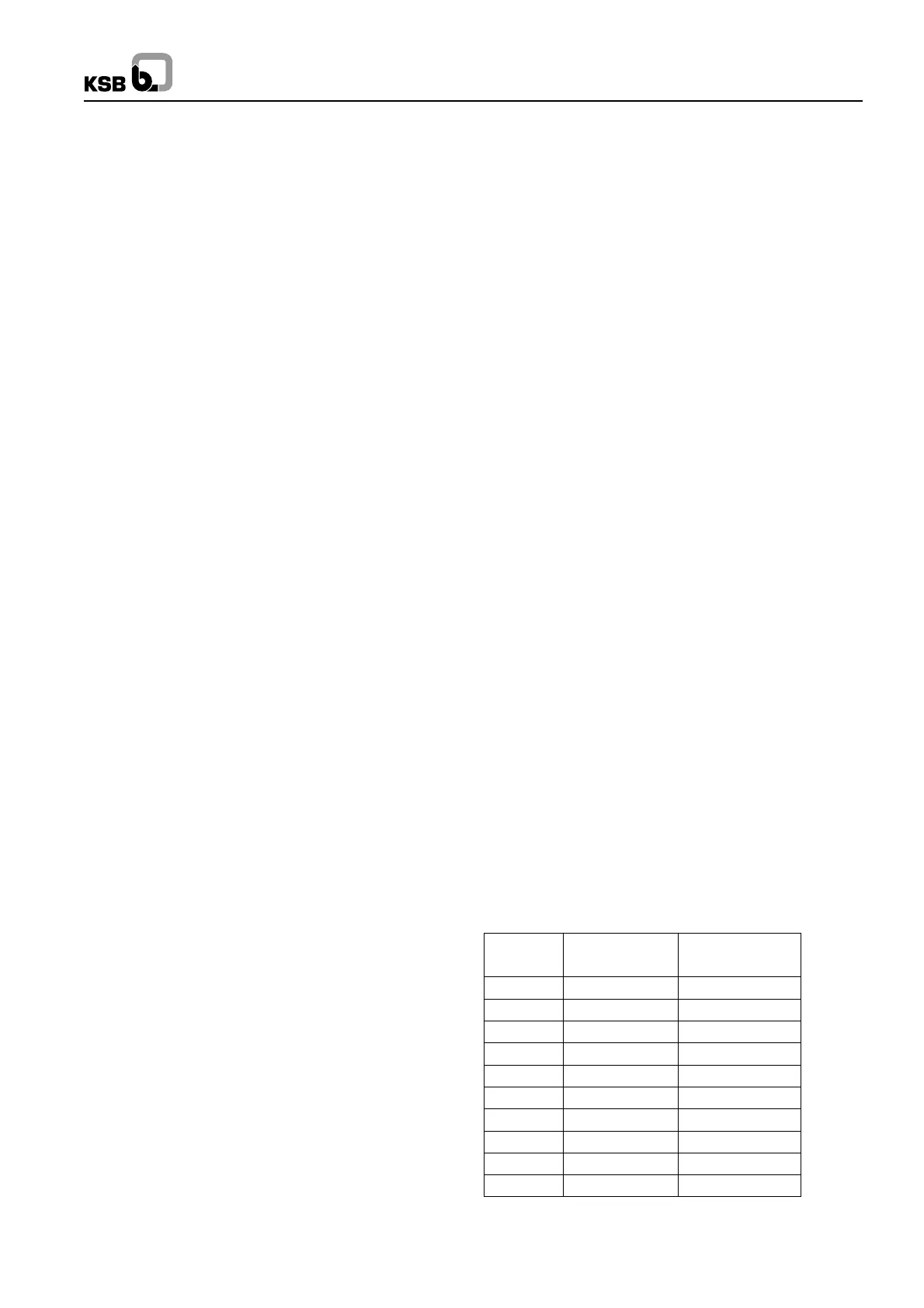

Please refer Table no 1 & 2 for the weight of pump and motor

respectively.Weight of pumpset for respective stages needs to

be calculated from Table no. 1.

Pump Type

Approx. Wt. of Per stage

one stage pump Approx. Wt. (kg.)

UQD 112 20 1

UQD 152 20 1

UQD 182 20 1

UQD 212 25 1.5

BPD 242 30 3

BPD 273 30 3

BPD 302 30 3

BPI 322 40 5

BPHA 333 40 7

BPHA 384 40 7

Table No. 1 : Per Stage weight of the pump

Loading...

Loading...