5-5

Crankshaft

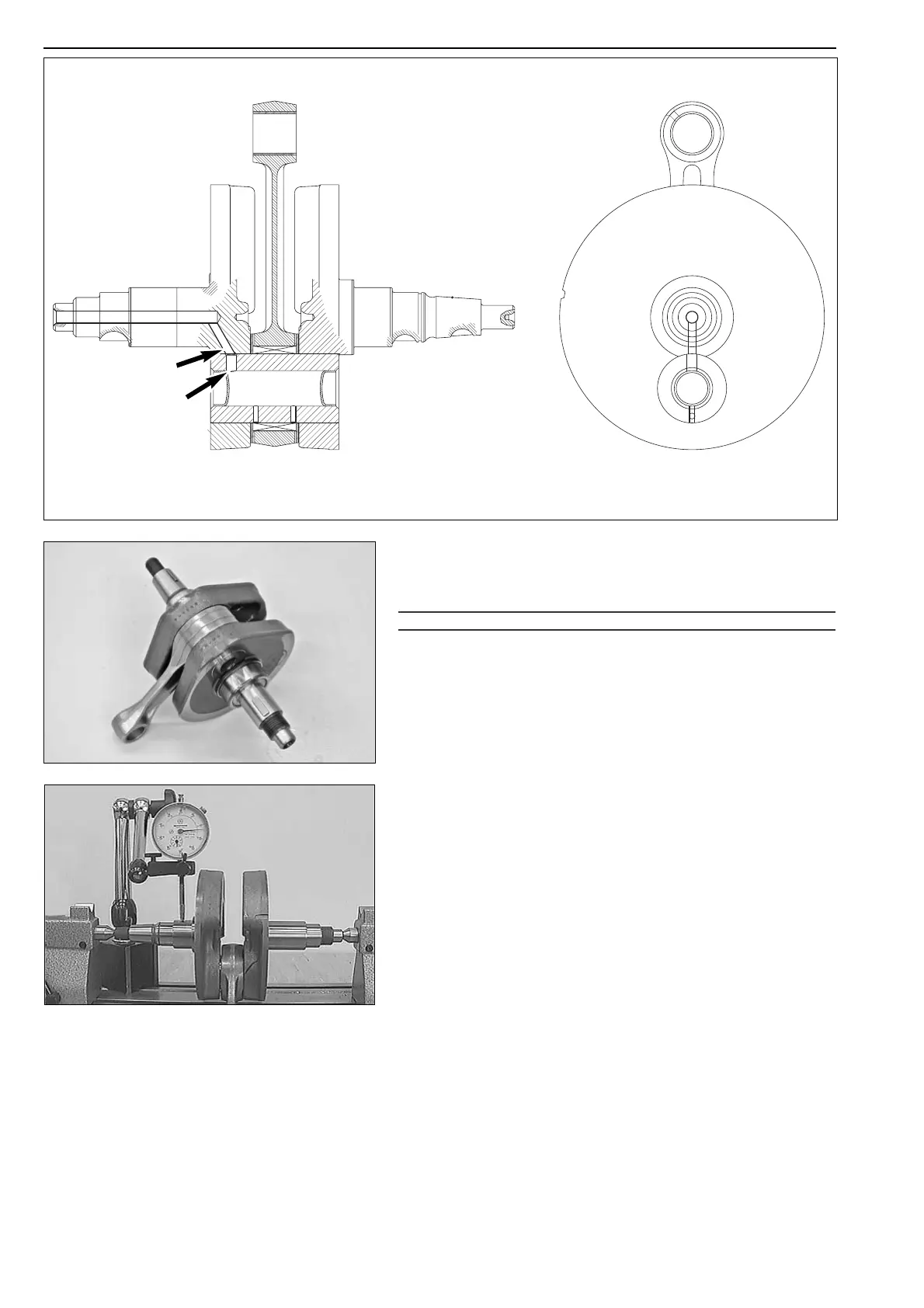

If replacing the conrod bearing, make sure the crank pin is in the right

position. The holes in the crankshaft web

A must align with the holes

in the crank pin

B.

!

CAUTION

!

I

F YOU PRESS IN THE CRANK PIN IN THE WRONG POSITION

, THE CONROD BEARING

WILL NOT BE SUPPLIED WITH ENGINE OIL

, WHICH WILL RESULT IN DAMAGE TO THE

BEARINGS

.

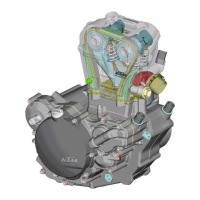

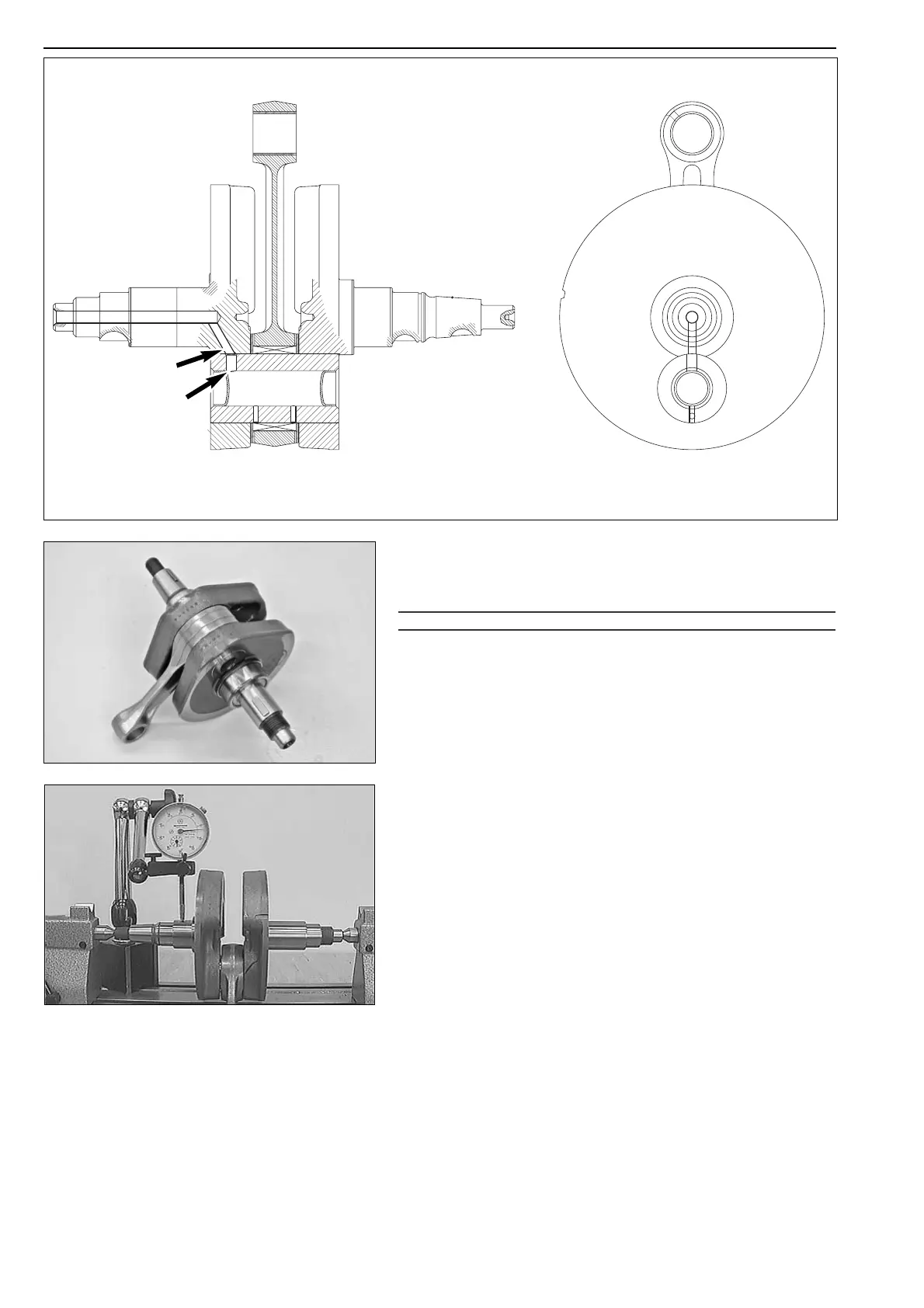

If you will continue to use the crankshaft, check the crankshaft journal

for runout. Place the crankshaft on a roller stand or similar support and

use a dial gauge to check the crankshaft journal for runout.

Crankshaft journal runout: max. 0.15 mm

Check the conrod bearing for radial and axial clearance.

Radial clearance: max. 0.03 mm

Axial clearance: max. 0.8 mm

A

B

Loading...

Loading...